Underdrive Clutch Inspection

INSPECT UNDERDRIVE CLUTCH PACK CLEARANCE

INSPECT NO. 1 UNDERDRIVE CLUTCH DISC

INSPECT UNDERDRIVE CLUTCH DRUM SUB-ASSEMBLY

INSPECT UNDERDRIVE CLUTCH RETURN SPRING SUB-ASSEMBLY

Underdrive Clutch -- Inspection |

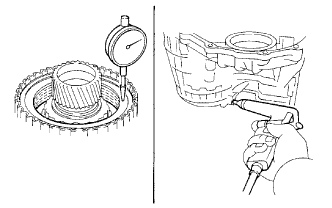

| 1. INSPECT UNDERDRIVE CLUTCH PACK CLEARANCE |

Install the underdrive clutch to the transaxle.

- NOTICE:

- Be careful not to damage the oil seal rings.

Install a dial indicator as shown in the illustration.

Measure the underdrive clutch pack clearance while applying and releasing compressed air (392 kPa, 4.0kgf/cm2, 57 psi)

- Standard pack clearance:

- 1.51 to 1.90 mm (0.0594 to 0.0748 in.)

If the pack clearance is not as specified, inspect the discs, plates and flange.

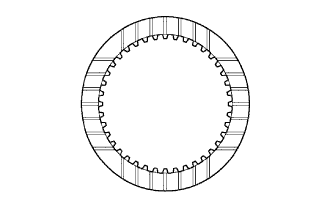

| 2. INSPECT NO. 1 UNDERDRIVE CLUTCH DISC |

Check to see if the sliding surface of the disc, plate and flange are worn or burnt. If necessary, replace them.

- HINT:

- If the lining of the discs is peeling off or discolored, or even if a part of the printed mark is defaced, replace all discs.

- Before assembling new discs, soak them in ATF for at least 15 minutes.

| 3. INSPECT UNDERDRIVE CLUTCH DRUM SUB-ASSEMBLY |

Using a caliper gauge measure the inside diameter of the underdrive clutch drum bush.

- Standard drum bush:

- 37.06 to 37.08 mm (1.4591 to 1.4598 in.)

- Maximum drum bush:

- 37.13 mm (1.4618 in.)

If the inside diameter is greater then the maximum, replace the underdrive clutch drum sub-assembly.

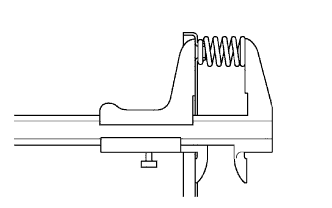

| 4. INSPECT UNDERDRIVE CLUTCH RETURN SPRING SUB-ASSEMBLY |

Using a vernier caliper, measure the free length of the spring together with the spring seat.

- Standard free length:

- 17.14 mm (0.6752 in.)