Direct Clutch Disassembly

INSPECT PACK CLEARANCE OF REVERSE CLUTCH

INSPECT PACK CLEARANCE OF DIRECT CLUTCH AND OVERDRIVE CLUTCH

REMOVE DIRECT MULTIPLE DISC CLUTCH DISC

REMOVE OVERDRIVE DIRECT CLUTCH DISC

REMOVE OVERDRIVE CLUTCH RETURN SPRING SUB-ASSEMBLY

REMOVE OVERDRIVE DIRECT CLUTCH PISTON

REMOVE OVERDRIVE DIRECT CLUTCH DRUM SUB-ASSEMBLY

REMOVE OVERDRIVE DIRECT CLUTCH O-RING

Direct Clutch -- Disassembly |

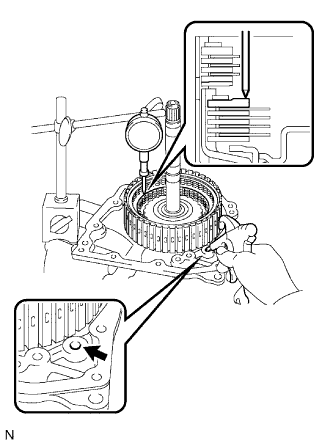

| 1. INSPECT PACK CLEARANCE OF REVERSE CLUTCH |

Install the intermediate shaft and needle roller bearing onto the rear transaxle cover.

Using a dial indicator, measure the reverse clutch pack clearance while applying and releasing compressed air (392 kPa, 4.0 kgf/cm2, 57 psi).

- Standard pack clearance:

- 0.60 to 0.82 mm (0.0236 to 0.0323 in.)

If the pack clearance is not as specified, inspect the discs, plates and flange.

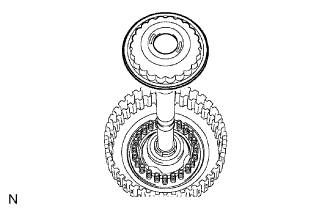

| 2. INSPECT PACK CLEARANCE OF DIRECT CLUTCH AND OVERDRIVE CLUTCH |

Using a dial indicator, measure the direct clutch and overdrive clutch pack clearance while applying and releasing compressed air (392 kPa, 4.0 kgf/cm2, 57 psi).

- Standard pack clearance:

- 0.61 to 0.83 mm (0.0240 to 0.0327 in.)

If the pack clearance is not as specified, inspect the discs, plates and flange.

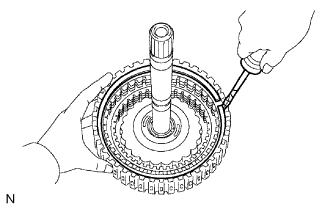

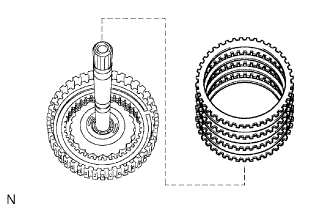

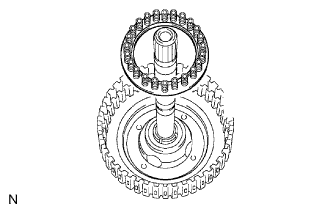

| 3. REMOVE DIRECT MULTIPLE DISC CLUTCH DISC |

Using a screwdriver, remove the snap ring from the intermediate shaft.

Remove the flange, 3 discs, 3 plates and cushion plate from the intermediate shaft.

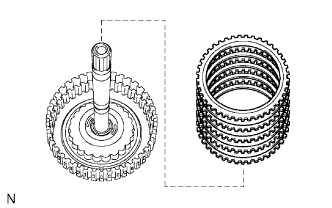

| 4. REMOVE OVERDRIVE DIRECT CLUTCH DISC |

Using a screwdriver, remove the snap ring from the intermediate shaft.

Remove the flange, 4 discs and 4 plates from the intermediate shaft.

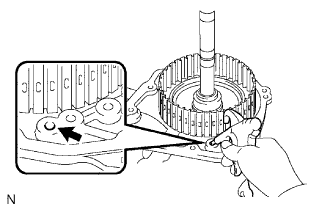

| 5. REMOVE OVERDRIVE CLUTCH RETURN SPRING SUB-ASSEMBLY |

Place SST on the clutch balancer and compress the spring with a press.

- SST

- 09387-00020

Using a snap ring expander, remove the snap ring from the direct clutch drum.

- NOTICE:

- Stop the press when the spring seat is lowered to a position 1 to 2 mm (0.039 to 0.078 in.) from the snap ring groove. This prevents the spring seat from being deformed.

- Do not expand the snap ring excessively.

Remove the clutch balancer from the direct clutch drum.

Remove the overdrive clutch return spring from the direct clutch drum.

| 6. REMOVE OVERDRIVE DIRECT CLUTCH PISTON |

Install the intermediate shaft on the transaxle rear cover.

Holding the direct clutch piston by hand, apply compressed air (392 kPa, 4.0 kgf/cm2, 57 psi) to the transaxle rear cover to remove the direct clutch piston.

| 7. REMOVE OVERDRIVE DIRECT CLUTCH DRUM SUB-ASSEMBLY |

Holding the direct clutch drum by hand, apply compressed air (392 kPa, 4.0 kgf/cm2, 57 psi) to the transaxle rear cover to remove the direct clutch drum.

| 8. REMOVE OVERDRIVE DIRECT CLUTCH O-RING |

Using a screwdriver, remove the O-ring from the direct clutch drum.