Differential Case Reassembly

INSTALL FRONT DIFFERENTIAL SIDE GEAR

INSTALL FRONT NO. 1 DIFFERENTIAL PINION SHAFT

INSPECT FRONT DIFFERENTIAL SIDE GEAR BACKLASH

INSTALL FRONT DIFFERENTIAL PINION SHAFT STRAIGHT PIN

INSTALL FRONT DIFFERENTIAL RING GEAR

Differential Case -- Reassembly |

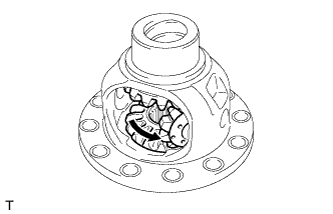

| 1. INSTALL FRONT DIFFERENTIAL SIDE GEAR |

Coat the contact surfaces of the front differential side gears with gear oil.

Install the 2 front No. 1 differential side gear thrust washers to the 2 front differential side gears.

Install the 2 front differential side gears, 2 front differential pinions, and 2 front differential pinion thrust washers to the front differential case.

- HINT:

- While rotating the front differential side gears, install the 2 front differential pinions and 2 front differential pinion thrust washers.

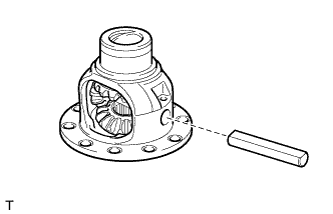

| 2. INSTALL FRONT NO. 1 DIFFERENTIAL PINION SHAFT |

Coat the front No. 1 differential pinion shaft with MP grease.

Install the front No. 1 differential pinion shaft to the front differential case so that the hole for the front differential pinion shaft straight pin is aligned with the hole in the front differential case.

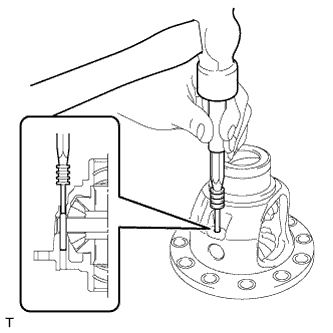

| 3. INSPECT FRONT DIFFERENTIAL SIDE GEAR BACKLASH |

Using a dial indicator, measure the front differential side gear backlash.

- Standard backlash:

- 0.05 to 0.20 mm (0.00197 to 0.00787 in.)

If the backlash is not as specified, replace the side gear thrust washers with washers of a different thickness. Use the table below to select a side gear thrust washer which will ensure that the backlash is within the specification.

- Standard Thrust Washer Thickness:

Mark

| Specified Condition

|

1

| 1.00 mm (0.0394 in.)

|

2

| 1.10 mm (0.0433 in.)

|

3

| 1.20 mm (0.0472 in.)

|

4

| 1.30 mm (0.0511 in.)

|

- HINT:

- Select washers of the same thickness for both the right and left sides.

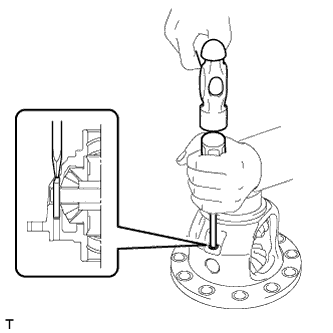

| 4. INSTALL FRONT DIFFERENTIAL PINION SHAFT STRAIGHT PIN |

Using a 5 mm pin punch and hammer, tap in the front differential pinion shaft straight pin to the front differential case.

Using a chisel and hammer, stake the front differential case.

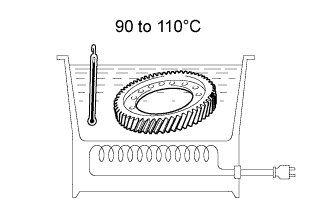

| 5. INSTALL FRONT DIFFERENTIAL RING GEAR |

Clean the contact surfaces of the front differential case and ring gear.

Heat the front differential ring gear to 90 to 110°C (194 to 230°F) in boiling water.

After the moisture on the ring gear has completely evaporated, quickly align the matchmarks on the ring gear and the differential case and install the ring gear to the differential case.

Text in Illustration*1

| Matchmark

|

Install the 12 bolts.

- Torque:

- 106 N*m{1081 kgf*cm, 78 ft.*lbf}