Manual Transaxle Assembly Installation

INSTALL SPEEDOMETER DRIVEN HOLE COVER SUB-ASSEMBLY

INSTALL CLUTCH RELEASE WITH BEARING CYLINDER ASSEMBLY

REMOVE CLUTCH RELEASE BLEEDER SUB-ASSEMBLY

INSPECT CLUTCH PIPE LINE

INSTALL CLUTCH RELEASE BLEEDER SUB-ASSEMBLY

INSTALL CLUTCH FLEXIBLE HOSE BRACKET

INSTALL CLUTCH ORIFICE ASSEMBLY

INSTALL CLUTCH RELEASE CYLINDER TO ACCUMULATOR TUBE

INSTALL ORIFICE TO FLEXIBLE HOSE TUBE

INSTALL REAR ENGINE MOUNTING BRACKET

INSTALL ENGINE MOUNTING BRACKET LH

INSTALL FRONT ENGINE MOUNTING BRACKET

INSTALL MANUAL TRANSAXLE ASSEMBLY

INSTALL ENGINE WIRE

INSTALL STARTER ASSEMBLY

INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

Manual Transaxle Assembly -- Installation |

- NOTICE:

- When the transaxle is removed, be sure to use a new clutch release with bearing cylinder and new installation bolts. Removal of the transaxle allows the compressed clutch release with bearing cylinder to return to its original position, and dust could damage the seal of the clutch release with bearing cylinder, possibly causing clutch fluid leaks.

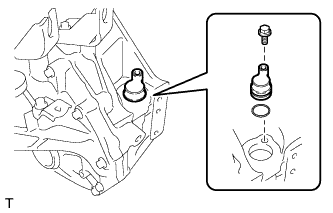

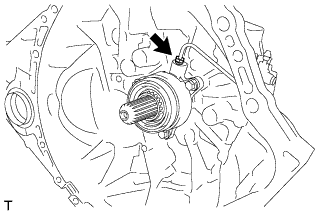

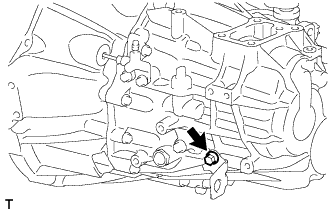

| 1. INSTALL SPEEDOMETER DRIVEN HOLE COVER SUB-ASSEMBLY |

Coat a new O-ring with gear oil.

Install the O-ring to the speedometer driven hole cover sub-assembly.

Install the speedometer driven hole cover sub-assembly to the transaxle case with the bolt.

- Torque:

- 5.5 N*m{56 kgf*cm, 49 in.*lbf}

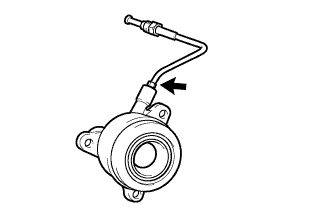

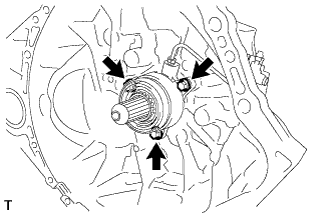

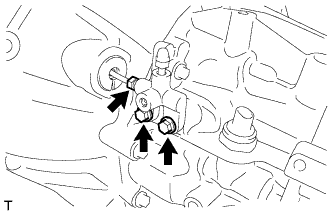

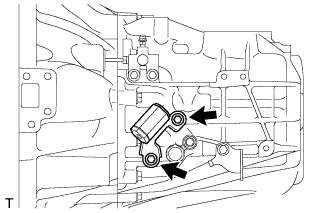

| 2. INSTALL CLUTCH RELEASE WITH BEARING CYLINDER ASSEMBLY |

Temporarily install the clutch release cylinder to bleeder tube to a new clutch release with bearing cylinder assembly.

Clean and degrease all installation surfaces for the clutch release with bearing cylinder assembly.

Install the clutch release with bearing cylinder assembly with 3 new bolts.

- Torque:

- 23 N*m{229 kgf*cm, 17 ft.*lbf}

- NOTICE:

- The clutch release with bearing cylinder and installation bolts cannot be reused and must be replaced with new ones.

- Clean and degrease all installation surfaces and make sure the clutch release with bearing cylinder fits securely with the transaxle during installation. The first bolt should be tightened by hand while holding the clutch release with bearing cylinder.

- Make sure that none of the clutch spline grease adheres to the clutch release with bearing cylinder.

- The clutch release with bearing cylinder cannot be disassembled.

Install the clutch tube boot to the manual transaxle assembly.

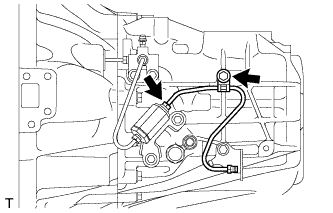

Temporarily install the clutch release cylinder to bleeder tube to the clutch release bleeder sub-assembly.

Temporarily install the clutch release bleeder sub-assembly with the 2 bolts.

Using a union nut wrench, install the clutch release cylinder to bleeder tube to the clutch release with bearing cylinder assembly.

- Torque:

- 15 N*m{155 kgf*cm, 11 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (RAV4_ACA30 RM0000018UO018X.html).

Apply clutch spline grease to the input shaft spline.

- Grease:

- Toyota Genuine Clutch Spline Grease or equivalent

Text in Illustration*1

| Clutch Spline Grease

|

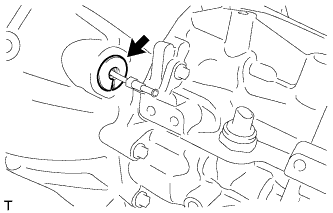

| 3. REMOVE CLUTCH RELEASE BLEEDER SUB-ASSEMBLY |

Separate the clutch release cylinder to bleeder tube from the clutch release bleeder sub-assembly.

Remove the 2 bolts and clutch release bleeder sub-assembly.

| 4. INSPECT CLUTCH PIPE LINE |

Using SST, apply a pressure of 100 kPa (1.0 kgf/cm2, 15 psi) to the clutch pipe location shown in the illustration and confirm that pressure is maintained for 15 seconds or more.

- SST

- 09992-00242

If the pressure drops, replace the clutch release cylinder to bleeder tube.

| 5. INSTALL CLUTCH RELEASE BLEEDER SUB-ASSEMBLY |

Temporarily install the clutch release cylinder to bleeder tube to the clutch release bleeder sub-assembly.

Install the clutch release bleeder sub-assembly with the 2 bolts.

- Torque:

- 17 N*m{170 kgf*cm, 12 ft.*lbf}

Using a union nut wrench, install the clutch release cylinder to bleeder tube.

- Torque:

- 15 N*m{155 kgf*cm, 11 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (RAV4_ACA30 RM0000018UO018X.html).

| 6. INSTALL CLUTCH FLEXIBLE HOSE BRACKET |

Install the clutch flexible hose bracket to the manual transaxle with the bolt.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

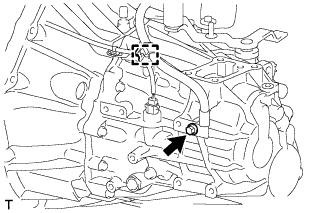

| 7. INSTALL CLUTCH ORIFICE ASSEMBLY |

Install the clutch orifice assembly with the 2 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

| 8. INSTALL CLUTCH RELEASE CYLINDER TO ACCUMULATOR TUBE |

Using a union nut wrench, install the clutch release cylinder to accumulator tube.

- Torque:

- 15 N*m{155 kgf*cm, 11 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (RAV4_ACA30 RM0000018UO018X.html).

| 9. INSTALL ORIFICE TO FLEXIBLE HOSE TUBE |

Temporarily tighten the orifice to flexible hose tube onto the clutch orifice assembly.

Install the orifice to flexible hose tube with the bolt.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

Using a union nut wrench, install the orifice to flexible hose tube.

- Torque:

- 15 N*m{155 kgf*cm, 11 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (RAV4_ACA30 RM0000018UO018X.html).

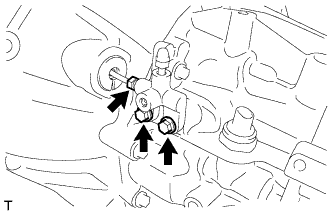

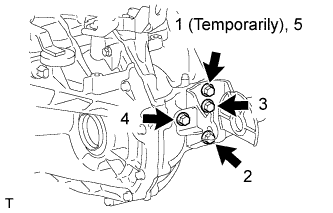

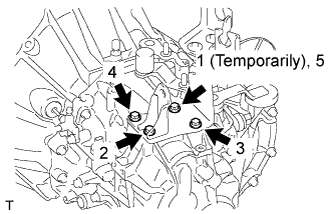

| 10. INSTALL REAR ENGINE MOUNTING BRACKET |

Install the rear engine mounting bracket with the 4 bolts.

- Torque:

- 45 N*m{459 kgf*cm, 33 ft.*lbf}

- HINT:

- As shown in the illustration, tighten the 4 bolts in order.

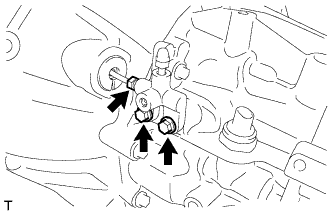

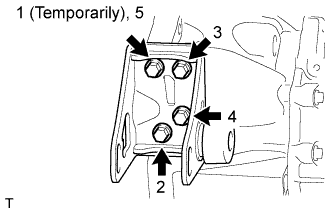

| 11. INSTALL ENGINE MOUNTING BRACKET LH |

Apply sealant to the 4 bolts.

- Sealant:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the engine mounting bracket LH with the 4 bolts.

- Torque:

- 64 N*m{653 kgf*cm, 47 ft.*lbf}

- HINT:

- As shown in the illustration, tighten the 4 bolts in order.

| 12. INSTALL FRONT ENGINE MOUNTING BRACKET |

Install the front engine mounting bracket with the 4 bolts.

- Torque:

- 64 N*m{653 kgf*cm, 47 ft.*lbf}

- HINT:

- As shown in the illustration, tighten the 4 bolts in order.

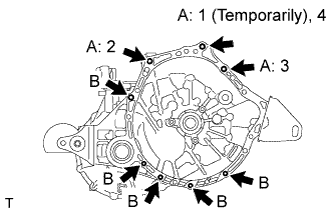

| 13. INSTALL MANUAL TRANSAXLE ASSEMBLY |

Align the input shaft with the clutch disc and install the manual transaxle to the engine.

- NOTICE:

- Make sure that the dowel pins are not loose, bent, damaged or scratched and then install the transaxle onto the engine with the contact surfaces of the engine and transaxle flat against each other.

- Insert the dowel pins into the dowel holes securely so that the end face of the transaxle assembly fits close against the engine assembly before tightening the bolts.

Install the 3 bolts labeled A in the order shown in the illustration, and then install the 5 bolts labeled B.

- Torque:

- Bolt A:

- 38 N*m{388 kgf*cm, 28 ft.*lbf}

- Bolt B:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

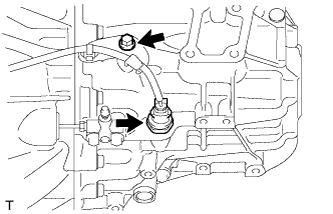

Connect the back-up light switch connector and install the engine wire to the manual transaxle with the bolt.

- Torque:

- 19 N*m{195 kgf*cm, 14 ft.*lbf}

Install the bolt, clamp and engine wire to the manual transaxle.

- Torque:

- 19 N*m{195 kgf*cm, 14 ft.*lbf}

| 15. INSTALL STARTER ASSEMBLY |

Install the starter assembly (RAV4_ACA30 RM000000YQ1012X.html).

| 16. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE |

Install the engine assembly with transaxle (RAV4_ACA30 RM000003PXK003X.html).