Continuously Variable Transaxle System Pattern Select Switch Sport Mode Circuit

K111F Cvt. Toyota Rav4. Aca30, 33, 38 Gsa33 Zsa30, 35

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

INSPECT NO. 1 PATTERN SELECT SWITCH ASSEMBLY

CHECK HARNESS AND CONNECTOR (NO. 1 PATTERN SELECT SWITCH ASSEMBLY - BODY GROUND)

CHECK HARNESS AND CONNECTOR (NO. 1 PATTERN SELECT SWITCH ASSEMBLY - ECM)

REPLACE ECM

PERFORM INITIALIZATION

CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM - Pattern Select Switch Sport Mode Circuit |

DESCRIPTION

The ECM memory contains the programs for the normal and sport shift patterns.By following the programs corresponding to the signals from the No. 1 pattern select switch assembly, the park/neutral position switch and other various sensors, the ECM switches the shift control solenoid valves on and off, and controls the transaxle gear ratio.

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.INSPECT NO. 1 PATTERN SELECT SWITCH ASSEMBLY |

Remove the No. 1 pattern select switch assembly.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Switch Condition

| Specified Condition

|

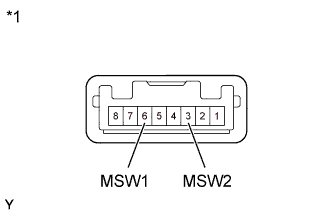

6 (MSW1) - 3 (MSW2)

| Pattern select switch on

| Below 1 Ω

|

6 (MSW1) - 3 (MSW2)

| Pattern select switch off

| 10 kΩ or higher

|

Text in Illustration*1

| Component without harness connected

(No. 1 Pattern Select Switch Assembly)

|

| | REPLACE NO. 1 PATTERN SELECT SWITCH ASSEMBLY |

|

|

| 2.CHECK HARNESS AND CONNECTOR (NO. 1 PATTERN SELECT SWITCH ASSEMBLY - BODY GROUND) |

Disconnect the No. 1 pattern select switch assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

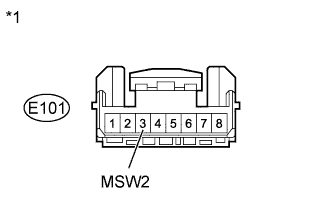

E101-3 (MSW2) - Body ground

| Always

| Below 1 Ω

|

Text in Illustration*1

| Front view of wire harness connector

(to No. 1 Pattern Select Switch Assembly)

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 3.CHECK HARNESS AND CONNECTOR (NO. 1 PATTERN SELECT SWITCH ASSEMBLY - ECM) |

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Switch Condition

| Specified Condition

|

A12-17 (PWMS) - Body ground

| Pattern select switch on

| Below 1 Ω

|

A12-17 (PWMS) - Body ground

| Pattern select switch off

| 10 kΩ or higher

|

Text in Illustration*1

| Front view of wire harness connector

(to ECM)

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

Replace the ECM (RAV4_ACA30 RM0000017UO01KX.html).

- NOTICE:

- Performing reset memory will clear the learned values of both the yaw rate sensor assembly*1 or deceleration sensor*2 (deceleration sensor 0 point calibration) and CVT oil pressure (CVT oil pressure calibration). Make sure to perform reset memory, yaw rate sensor assembly*1 or deceleration sensor*2 0 point calibration and CVT oil pressure calibration when replacing any of the parts shown in the following table:

Replaced Part

|

- Continuously variable transaxle assembly

- ECM

- Oil pressure sensor

- Yaw rate sensor assembly (w/ VSC)

- Deceleration sensor (w/o VSC)

- Brake actuator assembly (skid control ECU)

|

- After performing reset memory, always perform yaw rate sensor assembly*1 or deceleration sensor*2 (deceleration sensor 0 point) calibration first, and then CVT oil pressure calibration.

- Always perform 0 point calibration with the vehicle on level ground.

- Do not shake or vibrate the vehicle during 0 point calibration.

Using the intelligent tester, perform reset memory, deceleration sensor 0 point calibration and CVT oil pressure calibration (RAV4_ACA30 RM000003UQR002X.html).

Check that no DTC is stored.