Input Shaft -- Reassembly |

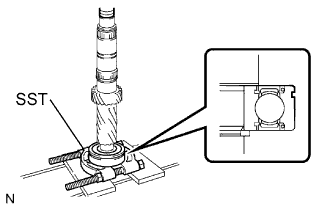

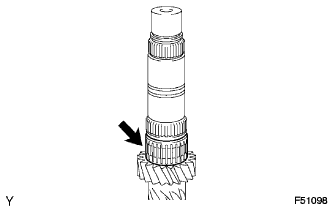

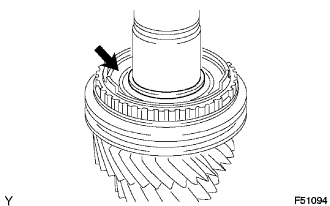

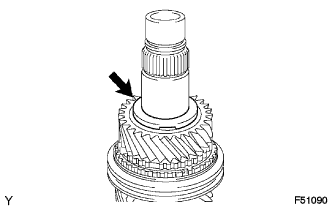

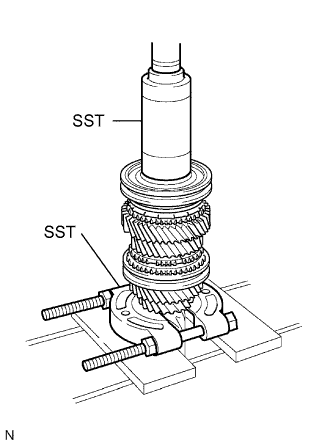

| 1. INSTALL INPUT SHAFT FRONT BEARING |

Using SST and a press, install the input shaft front bearing onto the input shaft.

- SST

- 09950-00020

- HINT:

- Make sure that the groove of the bearing faces the correct direction as shown in the illustration.

|

| 2. INSTALL INPUT SHAFT FRONT BEARING SNAP RING |

Select a snap ring that will allow minimum axial play.

- Standard clearance:

- 0.1 mm (0.004 in.) or less

- Snap ring thickness:

Part No. Thickness: mm (in.) Mark 90520-31026 2.65 to 2.70

(0.1043 to 0.1063)A 90520-31027 2.70 to 2.75

(0.1063 to 0.1083)B 90520-31028 2.75 to 2.80

(0.1083 to 0.1102)C 90520-31029 2.80 to 2.85

(0.1102 to 0.1122)D 90520-31030 2.85 to 2.90

(0.1122 to 0.1142)E 90520-31031 2.90 to 2.95

(0.1142 to 0.1161)F

|

Using a brass bar and hammer, install the snap ring onto the input shaft.

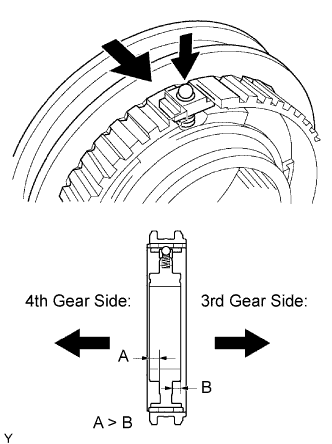

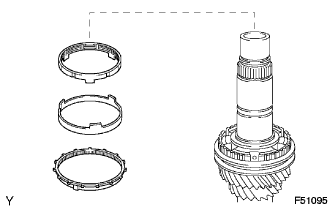

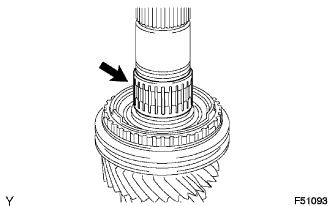

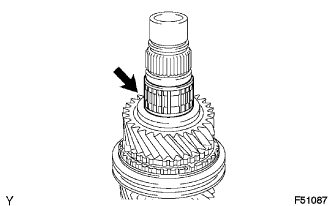

| 3. INSTALL NO. 2 TRANSMISSION CLUTCH HUB |

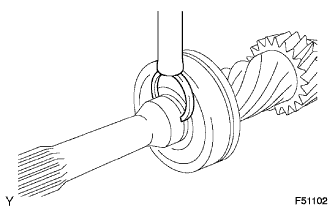

Apply a light coat of gear oil to the sleeve and hub.

|

Install the clutch hub sleeve onto the No. 2 transmission clutch hub.

Install the 3 shifting keys, 3 shifting key springs and 3 balls onto the clutch hub.

- NOTICE:

- Take care to prevent the ball from flying off.

- HINT:

- Make sure that the No. 2 transmission clutch hub faces the correct direction as shown in the illustration.

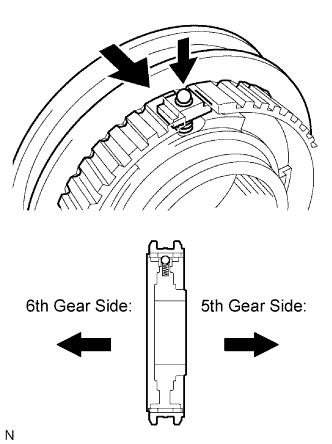

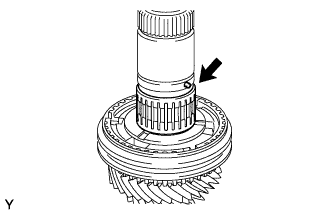

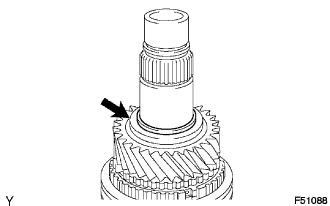

| 4. INSTALL NO. 3 TRANSMISSION CLUTCH HUB |

Apply a light coat of gear oil to the sleeve and hub.

|

Install the clutch hub sleeve onto the No. 3 transmission clutch hub.

Install the 3 shifting keys, 3 shifting key springs and 3 balls onto the clutch hub.

- NOTICE:

- Take care to prevent the ball from flying off.

- HINT:

- Make sure that the No. 2 transmission clutch hub faces the correct direction as shown in the illustration.

| 5. INSTALL 4TH GEAR NEEDLE ROLLER BEARING |

Coat the 4th gear needle roller bearing with gear oil, then install it onto the input shaft.

|

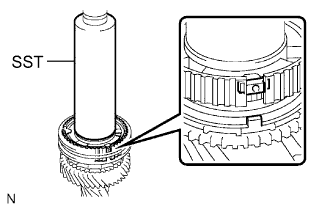

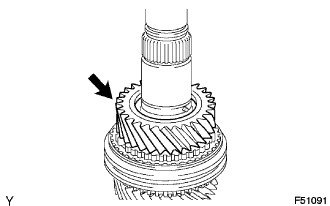

| 6. INSTALL 4TH GEAR |

Coat the 4th gear and No. 3 synchronizer ring with gear oil, then install them onto the input shaft.

Using SST and a press, install the No. 2 transmission clutch hub onto the input shaft.

- SST

- 09308-14010

- HINT:

- Align the convex portion of the synchronizer ring with the groove of the clutch hub.

|

Install the clutch hub and confirm that the gear and synchronizer ring move smoothly.

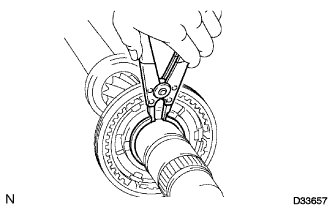

| 7. INSTALL NO. 2 CLUTCH HUB SETTING SHAFT SNAP RING |

Select a snap ring that will allow minimum axial play.

- Standard clearance:

- 0.1 mm (0.004 in.) or less

- Snap ring thickness:

Part No. Thickness: mm (in.) Mark 90520-42012 1.80 to 1.85

(0.0709 to 0.0728)A 90520-42013 1.85 to 1.90

(0.0728 to 0.0748)B 90520-42014 1.90 to 1.95

(0.0748 to 0.0768)C 90520-42015 1.95 to 2.00

(0.0768 to 0.0787)D 90520-42016 2.00 to 2.05

(0.0787 to 0.0807)E 90520-42017 2.05 to 2.10

(0.0807 to 0.0827)F 90520-42018 2.10 to 2.15

(0.0827 to 0.0846)G

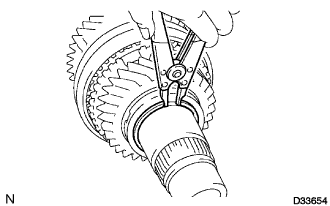

|

Using a snap ring expander, install the snap ring onto the input shaft.

| 8. INSTALL NO. 2 SYNCHRONIZER RING SET |

Coat the No. 2 synchronizer ring set with gear oil, then install it onto the input shaft.

|

| 9. INSTALL SPACER |

Coat the spacer with gear oil, and install it onto the input shaft.

|

| 10. INSTALL 3RD GEAR NEEDLE ROLLER BEARING |

Coat the 3rd gear needle roller bearing with gear oil, and install it onto the input shaft.

|

| 11. INSTALL STRAIGHT PIN |

Install the straight pin onto the input shaft.

|

| 12. INSTALL 3RD GEAR |

Coat the 3rd gear with gear oil, and install it onto the input shaft.

|

| 13. INSTALL 3RD GEAR THRUST WASHER |

Coat the 3rd gear thrust washer with gear oil, and install it onto the input shaft.

- HINT:

- Align the straight pin with the groove of the gear thrust washer and install it.

|

| 14. INSTALL GEAR THRUST WASHER SHAFT SNAP RING |

Select a snap ring that will allow minimum axial play.

- Standard clearance:

- 0.1 mm (0.004 in.) or less

- Snap ring thickness:

Part No. Thickness: mm (in.) Mark 90520-39026 2.07 to 2.12

(0.0815 to 0.0835)A 90520-39027 2.12 to 2.17

(0.0835 to 0.0854)B 90520-39028 2.17 to 2.22

(0.0854 to 0.0874)C 90520-39029 2.22 to 2.27

(0.0874 to 0.0894)D 90520-39030 2.27 to 2.32

(0.0894 to 0.0913)E 90520-39031 2.32 to 2.37

(0.0913 to 0.0933)F

|

Using a snap ring expander, install the snap ring onto the input shaft.

| 15. INSTALL SPACER |

Coat the spacer with gear oil, and install it onto the input shaft.

|

| 16. INSTALL 6TH GEAR NEEDLE ROLLER BEARING |

Coat the 6th gear needle roller bearing with gear oil, and install it onto the input shaft.

|

| 17. INSTALL 6TH GEAR |

Install the 6th gear onto the input shaft.

|

Install the synchronizer ring onto the input shaft.

Using SST and a press, install the clutch hub onto the input shaft.

- SST

- 09309-37010

09950-00020

Install the clutch hub and confirm that the gear and synchronizer ring move smoothly.

| 18. INSTALL TRANSMISSION CLUTCH HUB NO. 3 SHAFT SNAP RING |

Select a snap ring that will allow minimum axial play.

- Standard clearance:

- 0.1 mm (0.004 in.) or less

- Snap ring thickness:

Part No. Thickness: mm (in.) Mark 90520-33022 2.10 to 2.15

(0.0827 to 0.0847)A 90520-33023 2.15 to 2.20

(0.0847 to 0.0866)B 90520-33024 2.20 to 2.25

(0.0866 to 0.0886)C 90520-33025 2.25 to 2.30

(0.0886 to 0.0906)D 90520-33026 2.30 to 2.35

(0.0906 to 0.0925)E 90520-33027 2.35 to 2.40

(0.0925 to 0.0945)F 90520-33028 2.40 to 2.45

(0.0945 to 0.0965)G

|

Using a brass bar and a hammer, install the snap ring onto the input shaft.

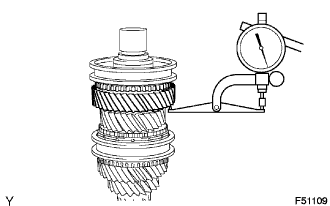

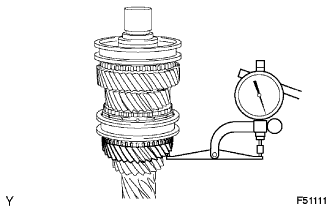

| 19. INSPECT 6TH GEAR THRUST CLEARANCE |

Using a dial indicator, measure the 6th gear thrust clearance.

- Standard clearance:

- 0.20 to 0.48 mm (0.0079 to 0.0189 in.)

|

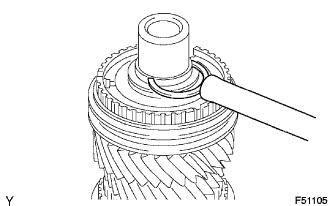

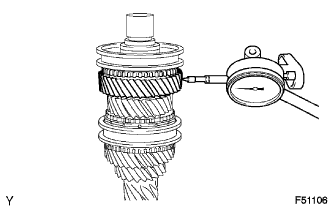

| 20. INSPECT 3RD GEAR THRUST CLEARANCE |

Using a feeler gauge, measure the 3rd gear thrust clearance.

- Standard clearance:

- 0.19 to 0.51 mm (0.0075 to 0.0201 in.)

|

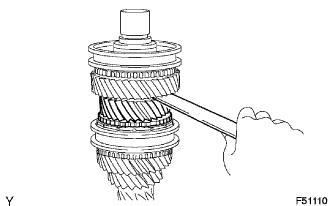

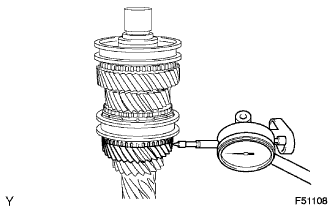

| 21. INSPECT 4TH GEAR THRUST CLEARANCE |

Using a dial indicator, measure the 4th gear thrust clearance.

- Standard clearance:

- 0.12 to 0.38 mm (0.0047 to 0.0150 in.)

|

| 22. INSPECT 6TH GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the 6th gear radial clearance.

- Standard clearance:

- 0.015 to 0.065 mm (0.0006 to 0.0026 in.)

|

| 23. INSPECT 3RD GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the 3rd gear radial clearance.

- Standard clearance:

- 0.015 to 0.067 mm (0.0006 to 0.0026 in.)

|

| 24. INSPECT 4TH GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the 4th gear radial clearance.

- Standard clearance:

- 0.015 to 0.067 mm (0.0006 to 0.0026 in.)

|