Engine. Lexus Is250, Is220D. Gse20 Ale20

DESCRIPTION

MONITOR DESCRIPTION

INSPECTION PROCEDURE

CHECK CATALYST RECORD OF DPNR THERMAL DETERIORATION

CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC 2002)

CHECK VACUUM HOSES AND TRANSMITTING PIPES (BLOCKAGE OF VACUUM HOSES AND TRANSMITTING PIPES)

CHECK FOR EXHAUST GAS LEAKAGE

READ VALUE OF INTELLIGENT TESTER (DIFFERENTIAL PRESSURE)

READ VALUE OF INTELLIGENT TESTER (EXHAUST GAS TEMPERATURE)

PERFORM ACTIVE TEST BY INTELLIGENT TESTER (ACTIVE THE DPNR REJUVENATE (PM))

READ VALUE OF INTELLIGENT TESTER (INJECTION FEEDBACK VAL AND INJECTION VOLUME)

CHECK EXHAUST FUEL ADDITION INJECTOR (INJECTION VOLUME)

CHECK TURBOCHARGER ACTUATOR

READ VALUE OF INTELLIGENT TESTER (MAF)

DTC P2002 Particulate Trap Efficiency Below Threshold (Bank1) |

DESCRIPTION

- HINT:

- For more information on the DPNR (*1) catalytic converter and TOYOTA D-CAT (*2) (Click here).

- If P2002 is present, refer to the DTC table for TOYOTA D-CAT (Click here).

- *1: Diesel Particulate-NOx Reduction system.

- *2: Diesel Clean Advanced Technology.

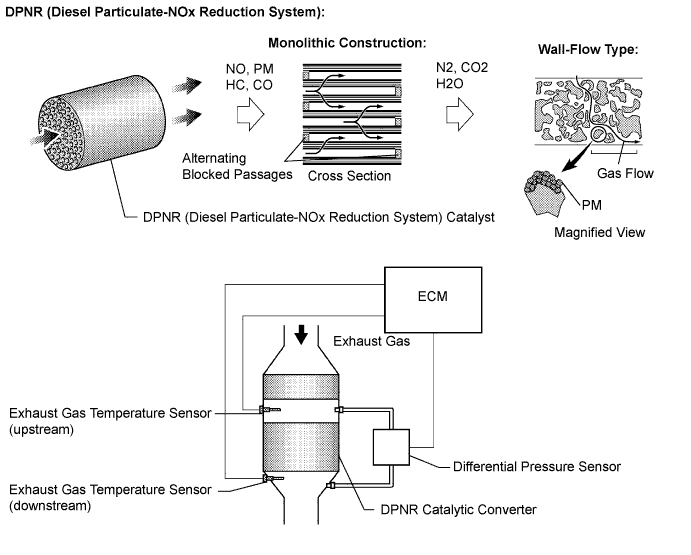

The DPNR catalyst has an ability to reduce nitrogen oxides (NOx), particulate matter (PM), hydrocarbons (HC) and carbon monoxides (CO). The DPNR catalyst is a monolithic type catalyst. Alternating passages in the catalyst have either their inlet or outlet blocked. This forces the exhaust gasses to flow through the walls of the passages (see illustration on the previous page). The passages are coated with a NOx absorptive deduction type catalyst. Due to the flow of the exhaust gasses through micro-cavities in the passage walls, it is called a "wall flow" type converter.DTC No.

| DTC Detection Condition

| Trouble Area

|

P2002

| Condition (a) or (b) is met (1 trip detection logic):

(a) Differential pressure exceeds a standard level for more than 10 seconds

(b) Exhaust gas temperature does not raise during DPNR catalyst regeneration

The DPNR catalyst thermal deterioration data exceeds the threshold.

| - DPNR catalytic converter (Manifold converter sub-assembly)

- Differential pressure sensor

- Differential pressure sensor vacuum hose is clogged

- Blockage in vacuum transmitting pipe sub-assembly

- Exhaust gas temperature sensor

- Fuel injector

- Exhaust fuel addition injector

- Turbocharger sub-assembly

- Exhaust gas leaks in TOYOTA D-CAT

- Mass air flow meter

- ECM

|

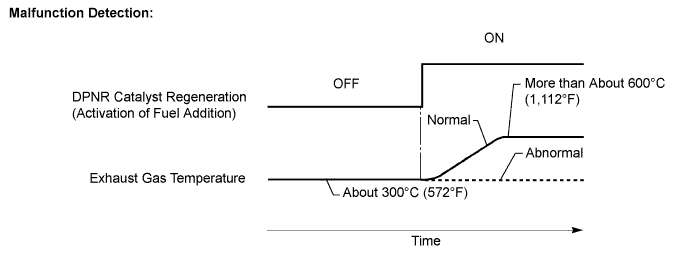

MONITOR DESCRIPTION

In order to detect abnormality in the DPNR (*3) catalytic converter, the ECM monitors an exhaust gas temperature as well as a differential pressure of the exhaust gas. For monitoring the differential pressure, the ECM compares the up-and downstream pressure of the DPNR catalytic converter. If the difference between the pressure is large, the ECM determines that the DPNR has become contaminated or is deteriorated, and illuminates the MIL.Furthermore, the ECM monitors an increase in the exhaust gas temperature while the exhaust fuel addition injector adds fuel under DPNR catalyst regeneration. The exhaust gas temperature during the DPNR catalyst regeneration normally rises from approximately 300°C (572°F) to approximately 600°C (1,112°F) or higher. If the temperature does not rise even if a certain period of time has elapsed, the ECM interprets this as a malfunction of the DPNR and illuminates the MIL.*3: Diesel Particulate-NOx Reduction system.

INSPECTION PROCEDURE

- NOTICE:

- After replacing the DPNR catalyst, clear the thermal deterioration data stored in the ECM.

- HINT:

- If a difference in pressure (DPNR DIFF PRESS) does not occur as engine speed is increased, the DPNR catalytic converter may be malfunctioning.

| 1.CHECK CATALYST RECORD OF DPNR THERMAL DETERIORATION |

Connect the intelligent tester to the DLC3.

Turn the engine switch ON (IG) and turn the intelligent tester ON.

Enter the following menus: "Powertrain / Engine / Data List / DPNR Catalyst Deteriorate"

- OK:

- Normal

| | REPLACE EXHAUST MANIFOLD CONVERTER SUB-ASSEMBLY |

|

|

| 2.CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC 2002) |

Connect the intelligent tester to the DLC3.

Turn the engine switch ON (IG) and turn the intelligent tester ON.

Enter the following menus: "Powertrain / Engine / DTC"

Read DTCs.

- Result:

Display (DTC output)

| Proceed to

|

P2002

| A

|

P2002 and other DTCs

| B

|

- HINT:

- If codes other than P2002 are output, perform troubleshooting for those DTCs first.

| 3.CHECK VACUUM HOSES AND TRANSMITTING PIPES (BLOCKAGE OF VACUUM HOSES AND TRANSMITTING PIPES) |

- CAUTION:

- Be careful not to get burned by exhaust gases during the following inspection.

Start the engine.

Check if there are exhaust gas pulsations from both vacuum hoses while the engine is idling.

| 4.CHECK FOR EXHAUST GAS LEAKAGE |

Check that there is no exhaust gas leak in the exhaust system components and differential pressure sensor vacuum hoses.

| | REPAIR OR REPLACE EXHAUST GAS LEAKAGE POINT |

|

|

| 5.READ VALUE OF INTELLIGENT TESTER (DIFFERENTIAL PRESSURE) |

Connect the intelligent tester to the DLC3.

Turn the engine switch ON (IG) and turn the intelligent tester ON.

Start the engine.

Enter the following menus: "Powertrain / Engine / Data List / Differential Pressure FB and MAF".

Check differential pressure.

- Result:

Engine Speed (Vehicle is stopped)

| Differential Pressure (kPa)

| Proceed to

|

3,000 rpm (No engine load)

| Less than MAF rate (mass air flow rate) x 0.31

| A

|

3,000 rpm (No engine load)

| More than MAF rate (mass air flow rate) x 0.31

| B

|

- HINT:

- If the differential pressure is more than a value that the intake air amount (MAF: g/sec) is multiplied by 0.31, DTC P2002 (Particulate Trap Efficiency Below Threshold [Bank 1]) will be present.

- The standards for the differential pressure sensor are as follows:

Reference:Condition

| Differential Pressure Output

| Sensor Condition

|

Engine switch ON (IG)

| Approximately 0 kPa

| Normal

|

Always

| 3 kPa

| Open or short circuit

|

3,000 rpm (No engine load)

| Negative output

| Incorrect arrangement of hose piping

|

| 6.READ VALUE OF INTELLIGENT TESTER (EXHAUST GAS TEMPERATURE) |

Connect the intelligent tester to the DLC3.

Turn the engine switch ON (IG) and turn the intelligent tester ON.

Start the engine.

Enter the following menus: "Powertrain / Engine / Data List / Initial Exhaust Temperature (In) and Initial Exhaust Temperature (Out)".

Check that exhaust gas temperature is within the specification below.

Reference:Condition

| Exhaust Gas Temperature

|

Idling after engine warm-up

| Constant at approximately 50 to 700°C (122 to 1,292°F) *3

|

*3: There should be no noise.

| | REPLACE EXHAUST GAS TEMPERATURE SENSOR CIRCUIT |

|

|

| 7.PERFORM ACTIVE TEST BY INTELLIGENT TESTER (ACTIVE THE DPNR REJUVENATE (PM)) |

Connect the intelligent tester to the DLC3.

Turn the engine switch ON (IG) and turn the intelligent tester ON.

Drive the vehicle.

Enter the following menus: "Powertrain / Engine / Data List / Active the DPNR Rejuvenate (PM).

Check exhaust gas temperature after switching the DPNR Rejuvenate (PM) from OFF to ON.

- OK:

- The exhaust gas temperature increases by 100°C or more.

| | REPLACE EXHAUST FUEL ADDITION INJECTOR ASSEMBLY |

|

|

| 8.READ VALUE OF INTELLIGENT TESTER (INJECTION FEEDBACK VAL AND INJECTION VOLUME) |

Select the following menu items in order and read the values.

- Injection Feedback Val #1, #2, #3, and #4

- Standard:

Item

| Engine Speed*

| Standard Range

| Description

|

Injection Feedback Val #1

| Idling

| -3.0 to 3.0 mm3

| Value of injector fuel injection volume compensates for differences in combustion condition of cylinders

- Positive values indicate control which corrects combustion deterioration

- Negative values indicate control which corrects excessive combustion pressure

- If problems exist, "Injection Feedback Val" may deviate from the -3.0 and 3.0 mm range

|

Injection Feedback Val #2

| Idling

| -3.0 to 3.0 mm3

|

Injection Feedback Val #3

| Idling

| -3.0 to 3.0 mm3

|

Injection Feedback Val #4

| Idling

| -3.0 to 3.0 mm3

|

Injection Volume

| Idling

| 3.9 to 7.0 mm3

| Fuel injection volume value controlled by ECU

- Controls NE signal, fuel temperature, engine coolant temperature, intake air temperature, boost pressure, atmospheric pressure, and EGR volume.

- If problems exist, "Injection Volume" may be outside the standard range

|

- HINT:

- *: The A/C switch and all accessory switches should be OFF, and the engine should be fully warmed up.

| | REPLACE INJECTOR ASSEMBLY |

|

|

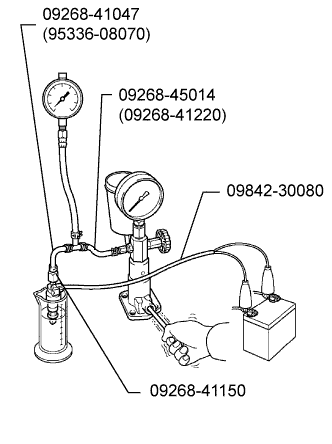

| 9.CHECK EXHAUST FUEL ADDITION INJECTOR (INJECTION VOLUME) |

- SST

- 09268-41047(95336-08070)

09268-45014(09268-41220)

09268-41150

Remove the exhaust fuel addition injector.

Attach the exhaust fuel addition injector to a nozzle tester.

- SST

- 09268-41047(95336-08070)

09268-45014(09268-41220)

09268-41150

Apply a pressure of 0.29 MPa (3.0 kgf/cm2, 42 psi) to the nozzle tester.

Connect SST (wire) to the exhaust fuel addition injector.

- SST

- 09842-30080

Inspect the injector.

- Standard:

Condition

| Result

|

Leave the injector undisturbed for 1 minute with fuel pressurized

| No leakage from the injector

|

Apply battery voltage to the injector

| Fuel is emitted from the injector

|

- HINT:

- Injection volume after leaving the exhaust fuel addition injector for 10 seconds with the pressurized fuel applied is as follows.

- Reference:

- 25 cm3 (1.5 cu.in.)

- The above is a reference value, thus, your reading may differ from this value depending on the measuring conditions etc.

- Check that the nozzle of the exhaust fuel addition injector is not clogged.

Reinstall the exhaust fuel addition injector.

| | REPLACE EXHAUST FUEL ADDITION INJECTOR ASSEMBLY |

|

|

| 10.CHECK TURBOCHARGER ACTUATOR |

Inspect the actuator.

- OK:

- The valve has no contamination and it moves smoothly.

| | REPLACE TURBOCHARGER SUB-ASSEMBLY |

|

|

| 11.READ VALUE OF INTELLIGENT TESTER (MAF) |

Connect the intelligent tester to the DLC3.

Start the engine and warm it up and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / Data List.

Select the following menu items in order and read the values.

- MAF

- Standard:

Item

| Engine Speed *1

| Standard Range

| Description

|

MAF *2, *3

| Engine switch ON (IG) (engine stopped)

| 0 g/s

| Intake air volume detected by mass air flow meter

|

Idling

| 2.5 to 5.5 g/s

|

3,000 rpm (no engine load)

| 49 to 57 g/s

|

3,000 rpm (driving with full throttle acceleration)*4

| 124 to 136 g/s

|

3,600 rpm (driving with full throttle acceleration)*4

| 151 to 163 g/s

|

- HINT:

- *1: The A/C switch and all accessory switches should be OFF with the engine fully warmed up.

- *2: This value is indicated when the ambient temperature is 25°C (77°F) and the atmospheric pressure is 101 kPa (758 mmHg, 29.83 in.Hg), and the stable boost pressure is maintained for approximately 10 seconds.

- *3: When the mass air flow meter malfunctions, the MAF output may deviate from the standard (referential) range when the engine idles and is accelerated from 3,000 to 4,000 rpm with full throttle acceleration.

- *4: Fully depress the accelerator pedal with the vehicle creeping at idle speed in 2nd gear.

| | REPLACE MAF METER ASSEMBLY |

|

|

| OK |

|

|

|

| REPLACE EXHAUST MANIFOLD CONVERTER SUB-ASSEMBLY |

|