Engine. Lexus Is250, Is220D. Gse20 Ale20

DESCRIPTION

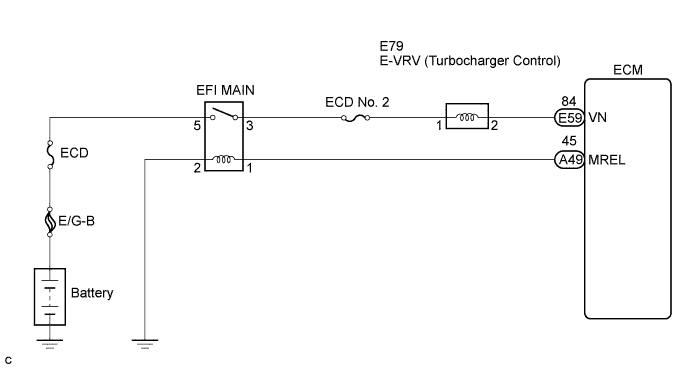

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC P0234, P0299 AND/OR P1251)

CHECK CONNECTION OF VACUUM HOSES

CHECK VACUUM (TURBOCHARGER - E-VRV FOR TURBOCHARGER CONTROL)

CHECK TERMINAL VOLTAGE (E-VRV POWER SOURCE)

CHECK E-VRV FOR TURBOCHARGER CONTROL (E-VRV OPERATION)

CHECK E-VRV FOR TURBOCHARGER CONTROL (E-VRV RESISTANCE)

CHECK HARNESS AND CONNECTOR (E-VRV FOR TURBOCHARGER CONTROL - ECM)

INSPECT TURBOCHARGER SUB-ASSEMBLY

INSPECT EGR VALVE ASSEMBLY

CHECK MANIFOLD ABSOLUTE PRESSURE SENSOR

DTC P0234 Turbocharger / Supercharger Overboost Condition |

DTC P0299 Turbocharger / Supercharger Underboost |

DTC P1251 Turbocharger / Supercharger Overboost Condition (Too High) |

DESCRIPTION

DTC No.

| DTC Detection Condition

| Trouble Area

|

P0234

| Turbochaging pressure is higher than the threshold for 60 seconds.

(1 trip detection logic)

| - E-VRV for turbocharger control

- Open or short in VRV circuit

- Turbocharger

- Vacuum hose

- EGR valve

- ECM

|

P0299

| Turbochaging pressure is lower than the threshold for 40 seconds when the turbochaging pressure deviates from the requirement.

(2 trip detection logic)

|

P1251

| Turbochaging pressure is higher than the requirement for 0.5 seconds.

(1 trip detection logic)

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- After replacing the ECM, the new ECM needs registration (Click here) and initialization (Click here).

| 1.CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC P0234, P0299 AND/OR P1251) |

Connect the intelligent tester to the DLC3.

Turn the engine switch ON (IG) and turn the intelligent tester ON.

Enter the following menus: "Powertrain / Engine / DTC".

Read DTCs.

- Result:

Display (DTC output)

| Proceed to

|

P0234, P0299 and/or P1251

| A

|

P0234, P0299 and/or P1251 and other DTCs

| B

|

| 2.CHECK CONNECTION OF VACUUM HOSES |

- HINT:

- Check the vacuum hoses of turbocharger system connections.

| | REPAIR OR REPLACE VACUUM HOSES |

|

|

| 3.CHECK VACUUM (TURBOCHARGER - E-VRV FOR TURBOCHARGER CONTROL) |

Using a three-way connector, connect a vacuum gauge to the hose between the E-VRV and turbocharger.

Warm up the engine coolant temperature to above 75°C (167°F).

Check the vacuum at the engine speed of 900 rpm.

- Result:

Vacuum

| Proceed to

|

0 kPa (0 mmHg, 0 in.Hg) to 50 kPa (375 mmHg, 14.8 in.Hg)

| A

|

Above 50 kPa (375 mmHg, 14.8 in.Hg)

| B

|

| 4.CHECK TERMINAL VOLTAGE (E-VRV POWER SOURCE) |

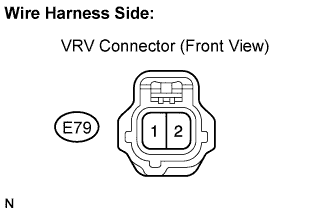

Disconnect the E79 E-VRV connector.

Measure the voltage.

- Standard voltage:

Tester Connection

| Specified Condition

|

VRV (E79-1) - Body ground

| 9 to 14 V

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 5.CHECK E-VRV FOR TURBOCHARGER CONTROL (E-VRV OPERATION) |

Check the E-VRV operation (Click here).

| | REPLACE E-VRV FOR TURBOCHARGER CONTROL |

|

|

| 6.CHECK E-VRV FOR TURBOCHARGER CONTROL (E-VRV RESISTANCE) |

Measure the E-VRV resistance (Click here).

- Standard resistance:

- 11.1 to 12.5 Ω

| | REPLACE E-VRV FOR TURBOCHARGER CONTROL |

|

|

| 7.CHECK HARNESS AND CONNECTOR (E-VRV FOR TURBOCHARGER CONTROL - ECM) |

Disconnect the E79 E-VRV connector.

Disconnect the E59 ECM connector.

Check the resistance between the wire harness side connectors.

- Standard resistance (Check for open):

Tester Connection

| Specified Condition

|

VN (E59-84) - VRV (E79-2)

| Below 1 Ω

|

- Standard resistance (Check for short):

Tester Connection

| Specified Condition

|

VN (E59-84) or VRV (E79-2) - Body ground

| 10 kΩ or higher

|

Reconnect the E-VRV connector.

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 8.INSPECT TURBOCHARGER SUB-ASSEMBLY |

Check the turbocharging pressure (Click here).

- Standard:

- 48 to 53 kPa (0.49 to 0.54 kgf/cm2, 6.9 to 7.7 psi)

| | REPLACE TURBOCHARGER SUB-ASSEMBLY |

|

|

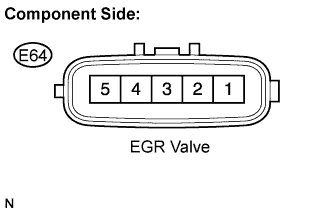

| 9.INSPECT EGR VALVE ASSEMBLY |

Disconnect the E64 EGR valve connector.

Measure the resistance between the terminals of the EGR valve.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

1 - 5

| 20°C (68°F)

| 6.5 to 7.5 Ω

|

Reconnect the EGR valve connector.

| | REPLACE EGR VALVE ASSEMBLY |

|

|

| 10.CHECK MANIFOLD ABSOLUTE PRESSURE SENSOR |

Connect an intelligent tester to the DLC3.

Turn the engine switch ON (IG) and turn the tester on.

Select the following menu items: Powertrain / Engine and ECT / Data List / Map and Atmosphere Pressure.

Read the value displayed on the tester.

- OK:

- MAP:

- Same as atmospheric pressure.

- HINT:

- 1 bar of atmospheric pressure is 101 kPa.

Apply a negative pressure of 40 kPa (300 mmHg, 11.8 in.Hg) to the manifold absolute pressure sensor.

- OK:

- MAP:

- MAP decreases 40 kPa from atmospheric pressure.

Apply a positive pressure of 69 kPa (518 mmHg, 20.4 in.Hg) to the manifold absolute pressure sensor.

- OK:

- MAP:

- MAP increases 69 kPa from atmospheric pressure.

- HINT:

- Even if the value output from the manifold absolute sensor is within the standard level, there may be a problem with the sensor due to deterioration because of age.

| | REPLACE MANIFOLD ABSOLUTE PRESSURE SENSOR |

|

|