DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

PERFORM ACTIVE TEST BY INTELLIGENT TESTER

CHECK WIRE HARNESS (INTEGRATION CONTROL & PANEL +B)

CHECK INTEGRATION CONTROL & PANEL

CHECK WIRE HARNESS (INTEGRATION CONTROL & PANEL - COMBINATION METER ASSEMBLY)

CHECK WIRE HARNESS (MULTI-MEDIA MODULE DISPLAY +B)

CHECK MULTI-MEDIA MODULE DISPLAY

CHECK WIRE HARNESS (MULTI-MEDIA MODULE DISPLAY - COMBINATION METER ASSEMBLY)

INSPECT SEPARATE TYPE FRONT SEAT CUSHION COVER (OCCUPANT DETECTION SENSOR)

CHECK WIRE HARNESS (COMBINATION METER ASSEMBLY - FRONT SEAT INNER BELT RH)

REPLACE FRONT SEAT INNER BELT ASSEMBLY (PASSENGER SIDE)

SEAT BELT WARNING SYSTEM - Front Passenger Side Seat Belt Warning Light Malfunction |

DESCRIPTION

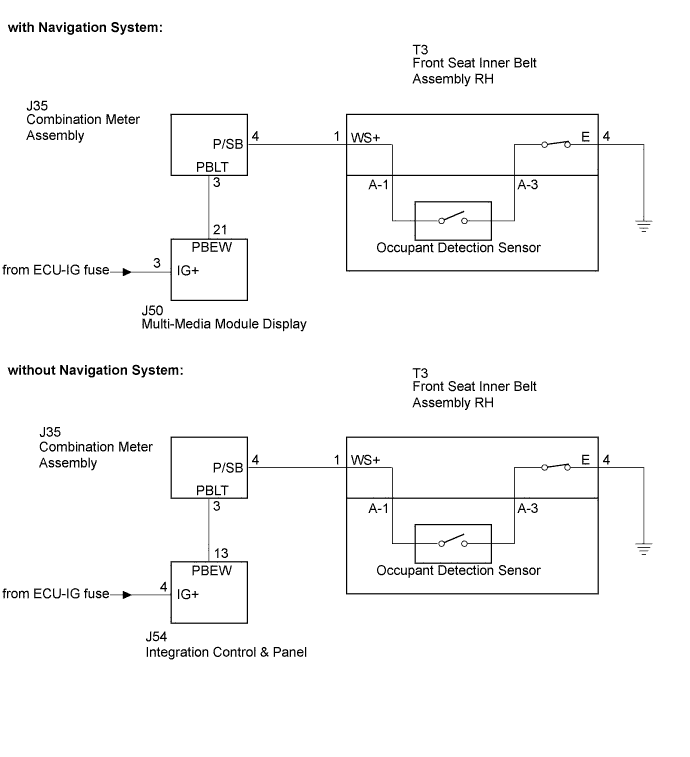

with Navigation System:The combination meter assembly detects the state of the front seat inner belt assembly RH when the front passenger seat is occupied with the engine switch on (IG). If the front passenger seat belt is not fastened, the front seat belt warning light on the multi-media module display blinks. If the seat belt is fastened, the warning light goes off.without Navigation System:The combination meter assembly detects the state of the front seat inner belt assembly RH when the front passenger seat is occupied with the engine switch on (IG). If the front passenger seat belt is not fastened, the front seat belt warning light on the integration control & panel assembly blinks. If the seat belt is fastened, the warning light goes off.

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.PERFORM ACTIVE TEST BY INTELLIGENT TESTER |

Operate the intelligent tester according to the steps on the display and select "ACTIVE TEST".

- METER:

Item

| Test Details

| Diagnostic Note

|

Indicat. lamp P-seat Belt

| P-SEAT BELT indicator light (OFF/ON)

| Confirm that the vehicle is stopped with the engine idling

|

- Result:

OK (without Navigation System)

| A

|

OK (with Navigation System)

| B

|

NG

| C

|

- OK:

- Switch condition (ON/OFF) can be switched by "ACTIVE TEST".

| |

|

| | GO TO COMBINATION METER SYSTEM |

|

|

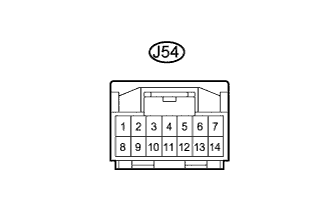

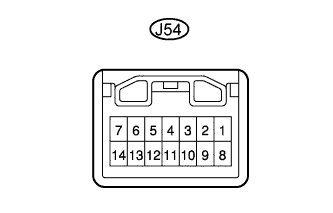

| 2.CHECK WIRE HARNESS (INTEGRATION CONTROL & PANEL +B) |

Disconnect the integration control & panel connector.

Measure the voltage according to the value(s) in the table below.

- Voltage:

Tester Connection

| Condition

| Specified Condition

|

J54-4 (IG+) - Body ground

| Engine switch on (IG)

| 10 to 14 V

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 3.CHECK INTEGRATION CONTROL & PANEL |

Disconnect the integration control & panel connector.

Apply battery voltage to the connector according to the table below.

- Voltage:

Condition

| Specified Condition

|

Battery positive (+) → Terminal 4 (IG)

Battery negative (-) → Terminal 13 (PBEW)

| Lights up (Seat belt warning light)

|

| | REPLACE INTEGRATION CONTROL & PANEL |

|

|

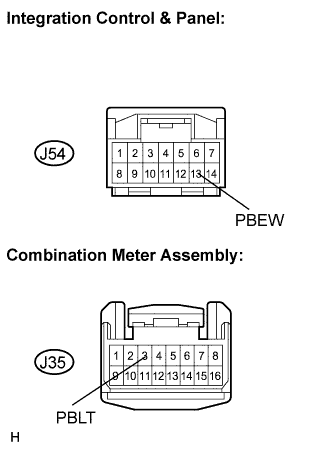

| 4.CHECK WIRE HARNESS (INTEGRATION CONTROL & PANEL - COMBINATION METER ASSEMBLY) |

Disconnect the combination meter assembly and integration control & panel connectors.

Measure the resistance according to the value(s) in the table below.

- Resistance:

Tester Connection

| Condition

| Specified Condition

|

J35-3 (PBLT) - J54-13 (PBEW)

| Always

| Below 1 Ω

|

J35-3 (PBLT) - Body ground

| Always

| 10 kΩ or higher

|

| NG |

|

|

|

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

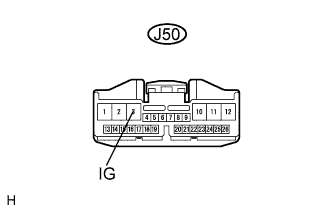

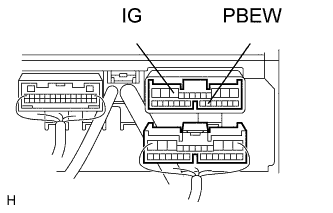

| 5.CHECK WIRE HARNESS (MULTI-MEDIA MODULE DISPLAY +B) |

Disconnect the multi-media module display connector.

Measure the voltage according to the value(s) in the table below.

- Voltage:

Tester Connection

| Condition

| Specified Condition

|

J50-3 (IG+) - Body ground

| Engine switch on (IG)

| 10 to 14 V

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 6.CHECK MULTI-MEDIA MODULE DISPLAY |

Disconnect the multi-media module display connector.

Apply battery voltage to the connector according to the table below.

- Voltage:

Condition

| Specified Condition

|

Battery positive (+) → Terminal 3 (IG)

Battery negative (-) → Terminal 21(PBEW)

| Lights up (Seat belt warning light)

|

| | REPLACE MULTI-MEDIA MODULE DISPLAY |

|

|

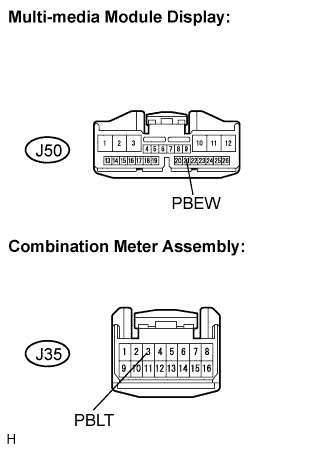

| 7.CHECK WIRE HARNESS (MULTI-MEDIA MODULE DISPLAY - COMBINATION METER ASSEMBLY) |

Disconnect the combination meter assembly and multi-media module display connectors.

Measure the resistance according to the value(s) in the table below.

- Resistance:

Tester Connection

| Condition

| Specified Condition

|

J35-3 (PBLT) - J50-21 (PBEW)

| Always

| Below 1 Ω

|

J35-3 (PBLT) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 8.INSPECT SEPARATE TYPE FRONT SEAT CUSHION COVER (OCCUPANT DETECTION SENSOR) |

Disconnect the occupant detection sensor connector.

Measure the resistance according to the value(s) in the table below.

- Resistance:

Tester Connection

| Condition

| Specified Condition

|

A-1 - A-3

| The passenger seat is occupied

| Below 100 Ω

|

A-1 - A-3

| The passenger seat is not occupied

| Below 1 MΩ

|

| | REPLACE SEPARATE TYPE FRONT SEAT CUSHION COVER (OCCUPANT DETECTION SENSOR) |

|

|

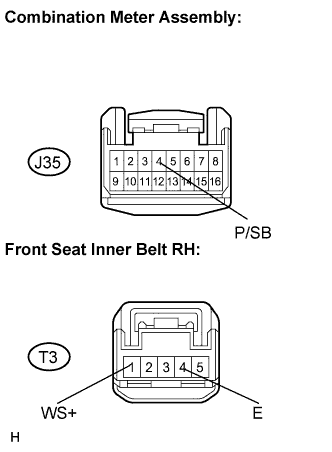

| 9.CHECK WIRE HARNESS (COMBINATION METER ASSEMBLY - FRONT SEAT INNER BELT RH) |

Disconnect the front seat inner belt RH connector.

Measure the resistance according to the value(s) in the table below.

- Resistance:

Tester Connection

| Condition

| Specified Condition

|

J35-4 (P/SB) - T3-1 (WS+)

| Always

| Below 1 Ω

|

J35-4 (E) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 10.REPLACE FRONT SEAT INNER BELT ASSEMBLY (PASSENGER SIDE) |

Replace the front seat inner belt assembly (Passenger side).

- OK:

- Seat belt warning operation returns to normal.

| | REPLACE COMBINATION METER |

|

|