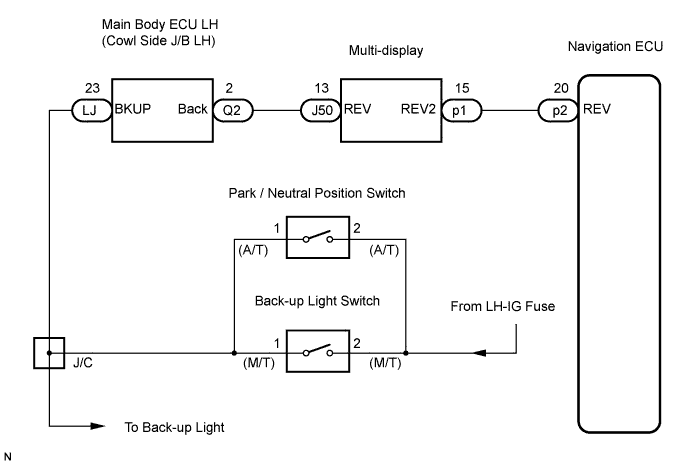

Navigation System Reverse Signal Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK BACK-UP LIGHT

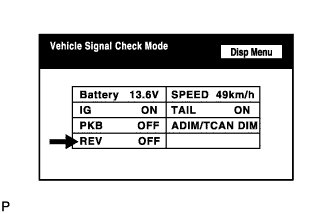

CHECK VEHICLE SIGNAL (DISPLAY CHECK MODE)

CHECK HARNESS AND CONNECTOR (NAVIGATION ECU - MULTI-DISPLAY)

INSPECT MULTI-DISPLAY

INSPECT MULTI-DISPLAY

CHECK HARNESS AND CONNECTOR (MULTI-DISPLAY - COWL SIDE J/B LH)

CHECK HARNESS AND CONNECTOR (JUNCTION CONNECTOR - COWL SIDE J/B LH)

NAVIGATION SYSTEM - Reverse Signal Circuit |

DESCRIPTION

The navigation ECU receives a reverse signal from the multi-display and information about the GPS antenna, and then adjusts vehicle position.

WIRING DIAGRAM

INSPECTION PROCEDURE

Move the shift lever to the R position and check if the back-up lights come on.

- OK:

- The back-up lights come on.

| 2.CHECK VEHICLE SIGNAL (DISPLAY CHECK MODE) |

Enter the "Display Check" mode (Vehicle Signal Check Mode) (Click here).

Check that the display changes between ON and OFF according to the shift lever operation (P and R).

- OK:

Shift Lever Position

| Display

|

Reverse

| ON

|

Except Reverse

| OFF

|

- HINT:

- This display is updated once per seconds. As a result, it is normal for the display to lag behind the actual change in the switch.

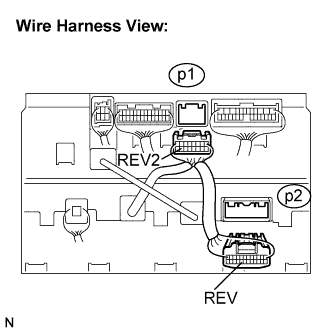

| 3.CHECK HARNESS AND CONNECTOR (NAVIGATION ECU - MULTI-DISPLAY) |

Disconnect multi-display connector p1 and navigation ECU connector p2.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

REV2 - REV

| Always

| Below 1 Ω

|

REV2 - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

Reconnect the multi-display connector p1.

Measure the voltage according to the value(s) in the table below.

- Standard voltage:

Tester Connection

| Condition

| Specified condition

|

REV - Body ground

| Engine switch is on (IG).

Shift lever is moved to Reverse position.

| 10 to 14 V

|

REV - Body ground

| Engine switch is on (IG).

Shift lever is moved to any position except Reverse.

| Below 1 V

|

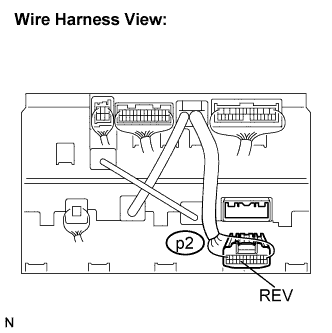

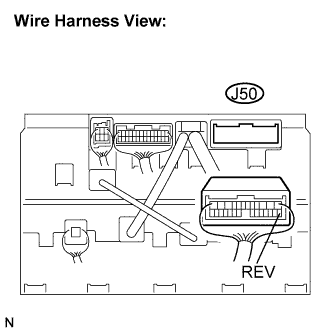

Disconnect the multi-display connector J50.

Measure the voltage according to the value(s) in the table below.

- Standard voltage:

Tester Connection

| Condition

| Specified condition

|

REV - Body ground

| Engine switch is on (IG).

Shift lever is moved to Reverse position.

| 10 to 14 V

|

REV - Body ground

| Engine switch is on (IG).

Shift lever is moved to any position except Reverse.

| Below 1 V

|

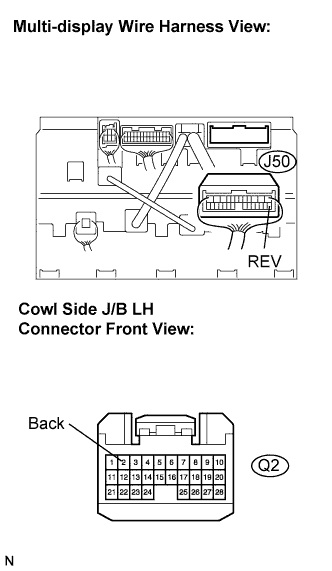

| 6.CHECK HARNESS AND CONNECTOR (MULTI-DISPLAY - COWL SIDE J/B LH) |

Disconnect the multi-display connector J50 and cowl side J/B LH connector Q2.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

REV - Back

| Always

| Below 1 Ω

|

REV - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

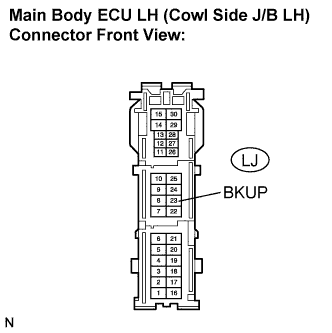

| 7.CHECK HARNESS AND CONNECTOR (JUNCTION CONNECTOR - COWL SIDE J/B LH) |

Disconnect the main body ECU LH (cowl side J/B LH) connector LJ.

Measure the voltage according to the value(s) in the table below.

- Standard voltage:

Tester Connection

| Condition

| Specified condition

|

BKUP - Body ground

| Engine switch is on (IG).

Shift lever is moved to Reverse position.

| 10 to 14 V

|

BKUP - Body ground

| Engine switch is on (IG).

Shift lever is moved to any position except Reverse.

| Below 1 V

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| OK |

|

|

|

| REPLACE MAIN BODY ECU LH (COWL SIDE J/B LH) |

|