Brake. Lexus Is250, Is220D. Gse20 Ale20

DESCRIPTION

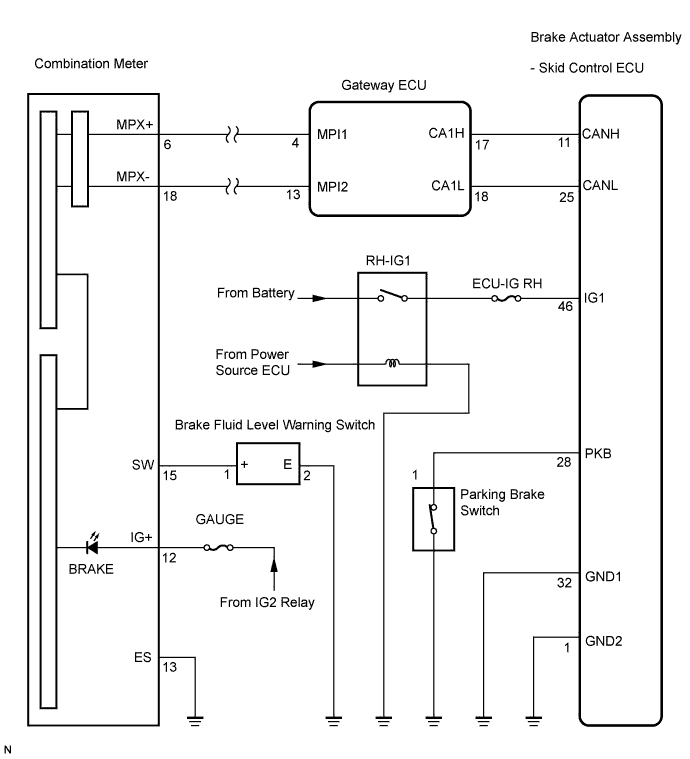

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK CAN COMMUNICATION SYSTEM

CHECK MULTIPLEX COMMUNICATION SYSTEM

CHECK IF SKID CONTROL ECU CONNECTOR IS SECURELY CONNECTED

CHECK BATTERY

INSPECT SKID CONTROL ECU (IG1 TERMINAL)

INSPECT SKID CONTROL ECU (GND TERMINAL)

INSPECT PARKING BRAKE SWITCH

CHECK HARNESS AND CONNECTOR (SKID CONTROL ECU - PARKING BRAKE SWITCH)

INSPECT BRAKE FLUID LEVEL WARNING SWITCH

CHECK HARNESS AND CONNECTOR (COMBINATION METER - BRAKE FLUID LEVEL WARNING SWITCH)

INSPECT COMBINATION METER ASSEMBLY

VEHICLE STABILITY CONTROL SYSTEM (w/o VDIM) - Brake Warning Light Remains ON |

DESCRIPTION

The skid control ECU is connected to the combination meter via CAN and multiplex communications.If any of the following is detected, the BRAKE warning light remains on:- The skid control ECU connector is disconnected from the skid control ECU.

- The brake fluid level is insufficient.

- The parking brake is applied.

- The EBD is defective.

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- When replacing the brake actuator assembly, perform zero point calibration (Click here).

| 1.CHECK CAN COMMUNICATION SYSTEM |

Check if the CAN communication system DTC is output (Click here for LHD, or Click here for RHD).

- Result:

Condition

| Proceed to

|

DTC is not output

| A

|

DTC is output

| B

|

| | INSPECT CAN COMMUNICATION SYSTEM |

|

|

| 2.CHECK MULTIPLEX COMMUNICATION SYSTEM |

Check if the multiplex communication system DTC is output (Click here).

- Result:

Condition

| Proceed to

|

DTC is not output

| A

|

DTC is output

| B

|

| | INSPECT MULTIPLEX COMMUNICATION SYSTEM |

|

|

| 3.CHECK IF SKID CONTROL ECU CONNECTOR IS SECURELY CONNECTED |

Check if the skid control ECU connector is securely connected.

- OK:

- The connector should be securely connected.

| | CONNECT CONNECTOR TO ECU CORRECTLY |

|

|

Check the battery voltage.

- Standard voltage:

- 11 to 14 V

| | CHECK AND REPLACE CHARGING SYSTEM OR BATTERY |

|

|

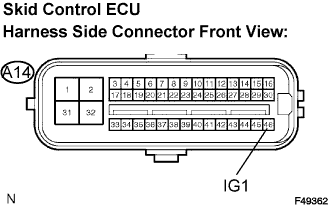

| 5.INSPECT SKID CONTROL ECU (IG1 TERMINAL) |

Disconnect the skid control ECU connector.

Turn the engine switch on (IG).

Measure the voltage according to the value(s) in the table below.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

A14-46 (IG1) - Body ground

| Engine switch on (IG)

| 10 to 14 V

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (IG1 CIRCUIT) |

|

|

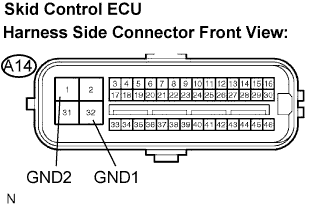

| 6.INSPECT SKID CONTROL ECU (GND TERMINAL) |

Turn the engine switch off.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

A14-32 (GND1) - Body ground

| Always

| Below 1 Ω

|

A14-1 (GND2) - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (GND CIRCUIT) |

|

|

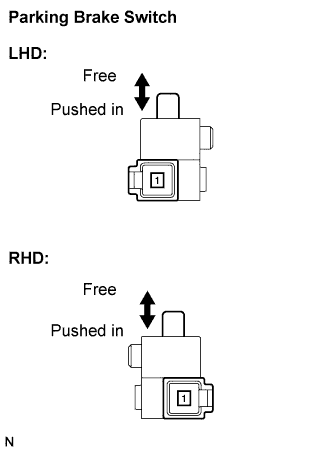

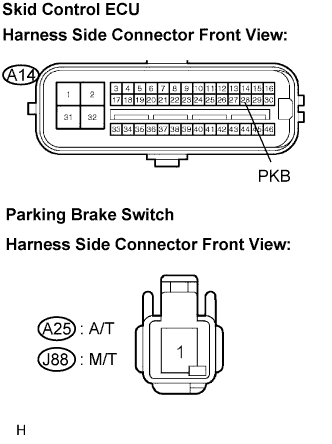

| 7.INSPECT PARKING BRAKE SWITCH |

Disconnect the parking brake switch connector.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

1 - Body ground

| Parking brake switch ON

(Switch pin free)

| Below 1 Ω

|

1 - Body ground

| Parking brake switch OFF

(Switch pin pushed in)

| 10 kΩ or higher

|

| | REPLACE PARKING BRAKE SWITCH |

|

|

| 8.CHECK HARNESS AND CONNECTOR (SKID CONTROL ECU - PARKING BRAKE SWITCH) |

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

- A/T:

Tester Connection

| Condition

| Specified Condition

|

A14-28 (PKB) - A25-1

| Always

| Below 1 Ω

|

A14-28 (PKB) - Body ground

| Always

| 10 kΩ or higher

|

- M/T:

Tester Connection

| Condition

| Specified Condition

|

A14-28 (PKB) - J88-1

| Always

| Below 1 Ω

|

A14-28 (PKB) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

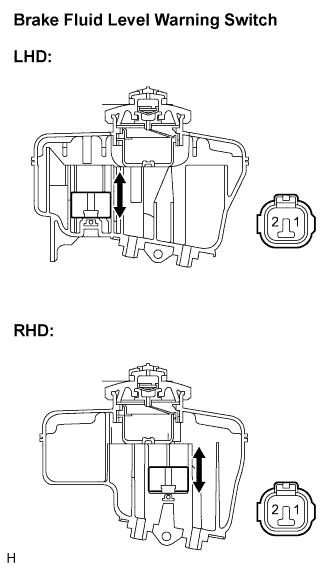

| 9.INSPECT BRAKE FLUID LEVEL WARNING SWITCH |

Remove the reservoir tank cap and strainer.

Disconnect the brake fluid level warning switch connector.

Measure the resistance according to the value(s) in the table below.

- HINT:

- A float is placed inside the reservoir. Its position can be changed by increasing/decreasing the level of brake fluid.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

1 - 2

| Float up (Switch OFF)

| 1.9 to 2.1 kΩ

|

1 - 2

| Float down (Switch ON)

| Below 1 Ω

|

- HINT:

- If there is no problem after finishing the above check, adjust the brake fluid level to the MAX level.

| | REPLACE BRAKE MASTER CYLINDER RESERVOIR SUB-ASSEMBLY (BRAKE FLUID LEVEL WARNING SWITCH) |

|

|

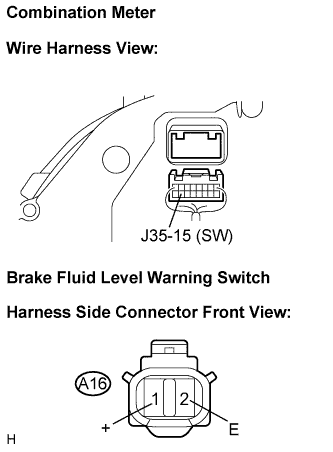

| 10.CHECK HARNESS AND CONNECTOR (COMBINATION METER - BRAKE FLUID LEVEL WARNING SWITCH) |

Disconnect the combination meter connector.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

J35-15 (SW) - A16-1 (+)

| Always

| Below 1 Ω

|

J35-15 (SW) - Body ground

| Always

| 10 kΩ or higher

|

A16-2 (E) - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 11.INSPECT COMBINATION METER ASSEMBLY |

Perform Active Test of the combination meter (meter CPU) using the intelligent tester (Click here).

- OK:

- The BRAKE warning light turns on or off in accordance with the intelligent tester.

- HINT:

- Reinstall the connectors and restore the vehicle to its prior condition before checking the combination meter.

- If troubleshooting has been carried out according to the Problem Symptoms Table, refer back to the table and proceed to the next step before replacing the part (Click here).

| | REPLACE COMBINATION METER ASSEMBLY |

|

|

| OK |

|

|

|

| REPLACE BRAKE ACTUATOR ASSEMBLY |

|