Engine -- On-Vehicle Inspection |

| 1. CHECK IGNITION TIMING |

Warm up the engine and stop the engine.

- NOTICE:

- A warmed up engine should have an engine coolant temperature of over 80°C (176°F), have an engine oil temperature of 60°C (140°F), and the engine rpm should be stabilized.

|

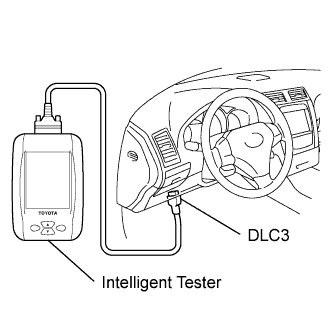

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

Start the engine and idle it.

Push the intelligent tester main switch ON.

Enter the following items: Powertrain / Engine and ECT / Data list / IGN Advance.

- Ignition timing:

- 8 to 12° BTDC @ idle (Shift lever on N)

- HINT:

- Please refer to the intelligent tester operator's manual for further details.

| 2. CHECK ENGINE IDLE SPEED |

Warm up the engine.

- NOTICE:

- A warmed up engine should have an engine coolant temperature of over 80°C (176°F) and an engine oil temperature of 60°C (140°F), and the engine rpm should be stabilized.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

- NOTICE:

- Switch off all accessories and A/C before connecting the intelligent tester.

Rev the engine at 2,500 rpm for approximately 90 seconds.

Push the intelligent tester main switch ON.

Enter the following items: Powertrain / Engine and ECT / Data list / Engine SPD.

- Idle speed:

- 700 to 800 rpm

- NOTICE:

- When checking the idle speed, the transmission should be in neutral.

- HINT:

- Please refer to the intelligent tester operator's manual for further details.

| 3. CHECK COMPRESSION |

Remove the V-bank cover.

Remove the air cleaner inlet and intake air pipe.

Disconnect the throttle control motor connector.

Remove the oil level gauge guide.

Remove the 8 ignition coils.

Remove the 8 spark plugs.

Disconnect the 8 injector connectors.

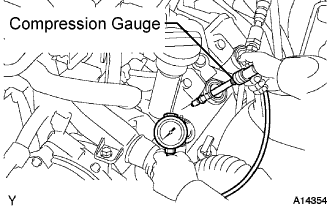

Check the cylinder compression pressure.

Insert a compression gauge into the spark plug hole.

Fully open the throttle.

While cranking the engine, measure the compression pressure.

- Compression pressure:

- 1,226 kPa (12.5 kgf/cm2, 178 psi) or more

- Minimum pressure:

- 981 kPa (10.0 kgf/cm2, 142 psi)

- Difference between each cylinder:

- 98 kPa (1.0 kgf/cm2, 14 psi)

- NOTICE:

- Always use a fully charged battery to obtain an engine speed of 250 rpm or more.

- Check the other cylinder's compression pressure in the same way.

- This measurement must be done as quickly as possible.

- HINT:

- If adding oil increases the compression, the piston rings and/or cylinder bore may be worn or damaged.

|

Connect the 8 injector connectors.

Install the 8 spark plugs.

Install the 8 ignition coils.

Install the oil level gauge guide.

Connect the throttle control motor connector.

Install the air cleaner inlet and intake air pipe.

Install the V-bank cover.

| 4. CHECK CO/HC |

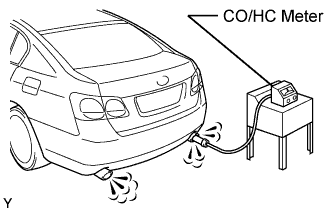

Start the engine.

|

Rev the engine at 2,500 rpm for approximately 180 seconds.

Insert a CO/HC meter testing probe at least 40 cm (1.3 ft.) into the tailpipe during idling.

Check CO/HC concentration at idle and/or 2,500 rpm.

- HINT:

- Complete the measurement within 3 minutes.

- Check regulations in your area when performing 2 mode CO/HC concentration testing (engine check at both idle speed and at 2,500 rpm).

If the CO/HC concentration does not comply with regulations, perform troubleshooting in the order given below.

Check the heated oxygen sensor operation (Click here).

See the table below for possible causes, and then inspect and repair.

CO HC Symptom Causes Normal High Rough idle 1. Faulty ignitions: - Incorrect timing

- Fouled, shorted or improperly gapped plugs.

3. Leaky intake and exhaust valves

4. Leaky cylinderLow High Rough idle

(fluctuating HC reading)1. Vacuum leaks: - PCV hose

- Intake manifold

- Throttle body

High High Rough idle

(black smoke from exhaust)1. Restricted air filter

2. Faulty SFI system:- Faulty pressure regulator

- Defective ECT sensor

- Faulty ECM

- Faulty injector

- Faulty throttle position sensor

- MAF sensor

- Incorrect timing