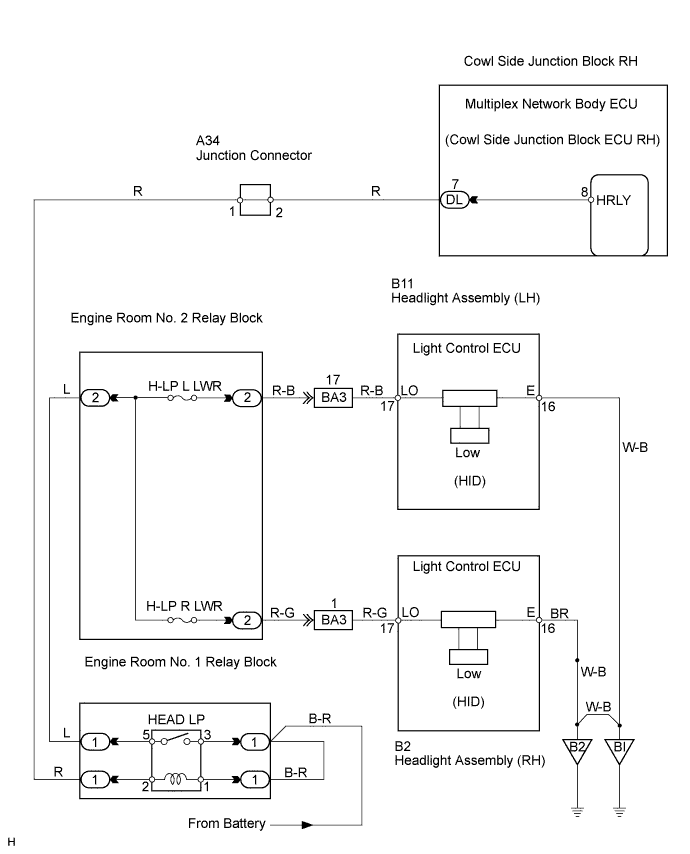

Lighting System Headlight Relay Circuit

Lighting. Lexus Gs430, Gs300. Uzs190 Grs190

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

PERFORM ACTIVE TEST BY INTELLIGENT TESTER

INSPECT FUSE (H-LP L LWR, H-LP R LWR)

INSPECT RELAY (Marking: HEAD LP)

CHECK WIRE HARNESS (COWL SIDE JUNCTION BLOCK RH - BATTERY)

CHECK WIRE HARNESS (HEADLIGHT (LOW LH OR LOW RH) - BATTERY AND BODY GROUND)

REPLACE HEADLIGHT ASSEMBLY (LOW LH OR LOW RH)

LIGHTING SYSTEM - Headlight Relay Circuit |

DESCRIPTION

The headlight relay is turned ON by operating the headlight switch.When the theft deterrent system is activated, it causes the ECU to turn the headlight relay on and off repeatedly at approximately 0.25 second intervals to flash the headlights.In this condition, if any of the following operations is performed, the ECU turns the headlight relay off to stop the headlight from flashing:- Unlock the driver door with a key.

- Turn the engine switch on (ACC) or on (IG).

- Unlock the doors with the wireless door lock control system.

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.PERFORM ACTIVE TEST BY INTELLIGENT TESTER |

Select the Active Test, use the intelligent tester to generate a control command, and then check that the headlight assembly (low) illuminates.

- Multiplex network body ECU :

Item

| Tester Details

| Diagnostic Note

|

Head Light

| Headlight relay ON / OFF

| -

|

- OK:

- Headlight assembly (low) illuminates.

| OK |

|

|

|

| PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE |

|

| 2.INSPECT FUSE (H-LP L LWR, H-LP R LWR) |

Remove the H-LP L LWR fuse from the engine room No. 2 relay block.

Remove the H-LP R LWR fuse from the engine room No. 2 relay block.

Measure the resistance of the fuses.

- Standard resistance:

- Below 1 Ω

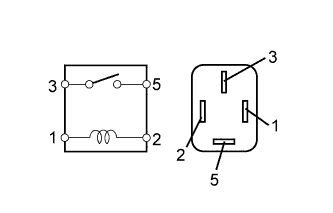

| 3.INSPECT RELAY (Marking: HEAD LP) |

Remove the HEAD LP relay from the engine room No. 1 relay block.

Measure the resistance of the HEAD LP relay.

- Standard resistance:

Tester Connection

| Specified Condition

|

3 - 5

| 10 kΩ or higher

|

3 - 5

| Below 1 Ω

(When battery voltage is applied to terminals 1 and 2)

|

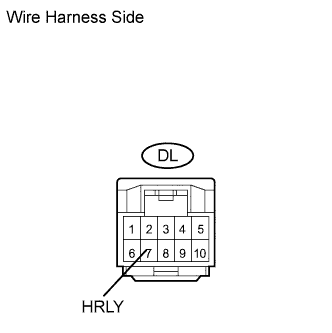

| 4.CHECK WIRE HARNESS (COWL SIDE JUNCTION BLOCK RH - BATTERY) |

Disconnect the DL junction block connector.

Measure the voltage of the wire harness side connector.

- Standard voltage:

Tester Connection

| Specified Condition

|

DL-7 (HEAD) - Body ground

| 10 to 14 V

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

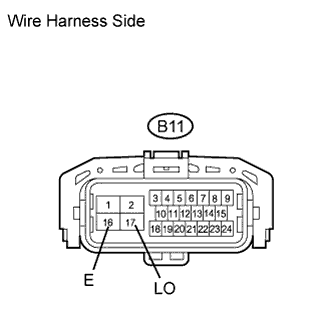

| 5.CHECK WIRE HARNESS (HEADLIGHT (LOW LH OR LOW RH) - BATTERY AND BODY GROUND) |

Check the wire harness between the headlight (Low LH) and battery, and the headlight (Low LH) and body ground.

Disconnect the B11 light connector.

Turn the light control switch to the ON (HEAD) position.

Measure the voltage and resistance of the wire harness side connector.

- Standard voltage:

Tester Connection

| Specified Condition

|

B11-17 (LO) - Body ground

| 10 to 14 V

|

- Standard resistance:

Tester Connection

| Specified Condition

|

B11-16 (E) - Body ground

| Below 1 Ω

|

Check the wire harness between the headlight (Low RH) and battery, and the headlight (Low RH) and body ground.

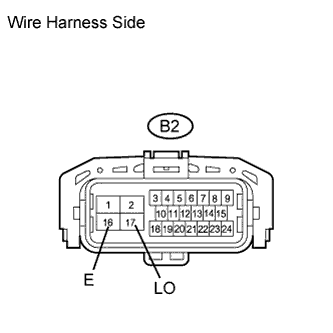

Disconnect the B2 light connector.

Turn the light control switch to the ON (HEAD) position.

Measure the voltage and resistance of the wire harness side connector.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

B2-17 (LO) - Body ground

| Engine switch on (IG)

| 10 to 14 V

|

- Standard resistance:

Tester Connection

| Specified Condition

|

B2-16 (E) - Body ground

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| 6.REPLACE HEADLIGHT ASSEMBLY (LOW LH OR LOW RH) |

Temporarily replace the headlight assembly (low LH or low RH) with a new or normally functioning one.

Check that the headlight assembly (low LH or low RH) illuminates.

- OK:

- Headlight assembly (low LH or low RH) illuminates.

| NG |

|

|

|

| PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE |

|