High Pressure Side Fuel Pump -- Installation |

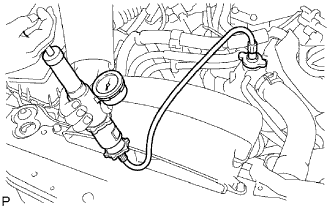

| 1. INSTALL HIGH PRESSURE SIDE FUEL PUMP |

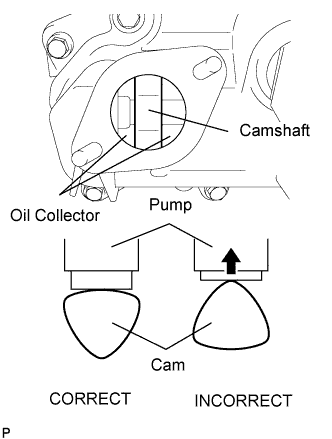

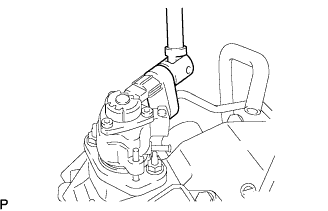

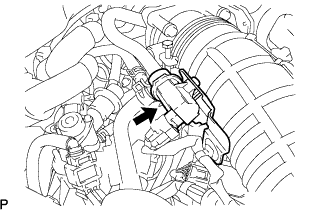

Turn the crankshaft until the flat of the cam is facing the cylinder head cover's fuel pump attachment hole, as shown in the illustration.

- HINT:

- When installing the fuel pump using the procedure described above: By not using the crankshaft pointed side to push up the pump activation surface, it is easier to install the fuel pump and No. 2 fuel pipe later.

|

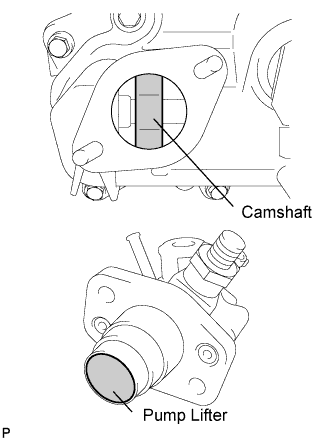

Pour 30 cc of engine oil through the cylinder head cover's fuel pump attachment hole into the cylinder head oil collector.

Apply a coat of engine oil to the pump activation cam and pump lifter part.

|

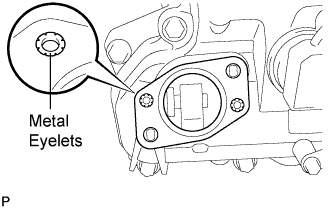

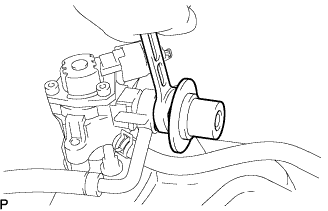

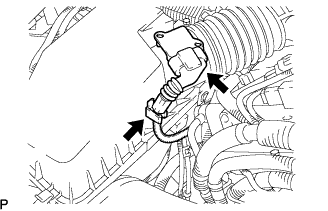

Install a new fuel pump insulator to the cylinder head cover. Then pass the 2 stud bolts through the holes of the fuel pump and set it on the insulator.

- NOTICE:

- Install the insulator so that the open sides of the metal eyelets are facing outward, as shown in the illustration.

|

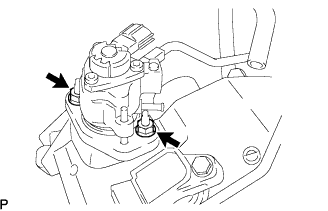

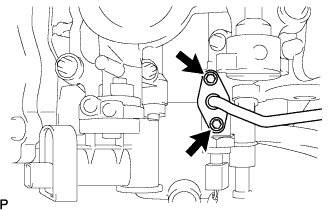

Install the union nut of the No. 1 fuel pipe without damaging its seal surface. Tighten the nut as much as possible by hand.

Install the 2 nuts and tighten them in several passes.

- Torque:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

|

Connect the fuel hose.

| 2. CONNECT NO. 2 FUEL PIPE |

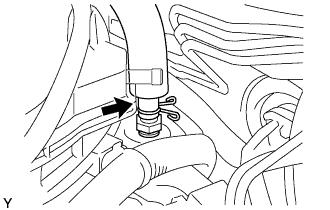

Using a 19 mm union nut wrench, connect the fuel pipe.

- Torque:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

|

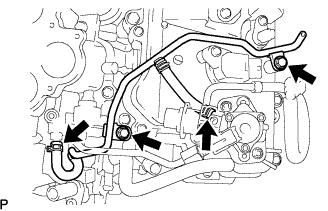

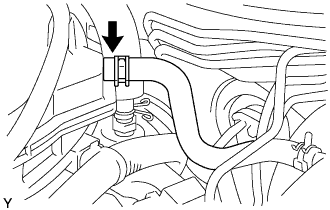

Install the No. 2 fuel pipe to the delivery pipe with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

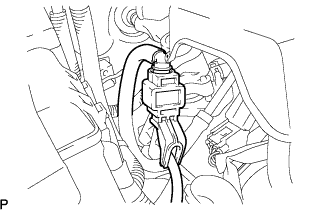

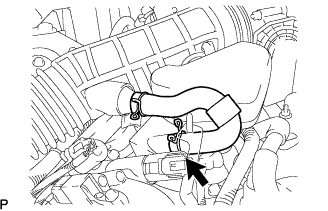

Connect the connector to the fuel pump.

| 3. REMOVE FUEL PRESSURE PULSATION DAMPER |

|

Install 2 new gaskets, the fuel main tube and pulsation damper to the fuel pump.

- Torque:

- 40 N*m{408 kgf*cm, 28 ft.*lbf}

| 4. INSTALL NO. 1 FUEL PIPE |

Install the No.1 fuel pipe with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

Connect the fuel pipe hose.

| 5. INSTALL INTAKE MANIFOLD |

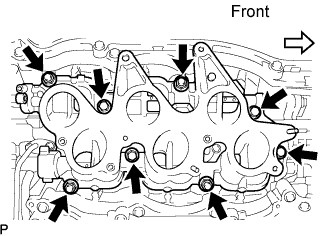

Install a new gasket and the intake manifold with the 4 bolts and 4 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

Connect the DC motor connector for the SCV.

Connect the SCV position sensor connector.

| 6. REMOVE INTAKE AIR SURGE TANK |

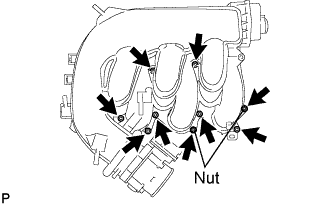

Install a new gasket to the intake air surge tank.

|

Install the intake air surge tank with the 2 nuts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

Using a 5 mm hexagon socket wrench, install the 7 bolts.

- Torque:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

Install the 2 surge tank stays with the 4 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

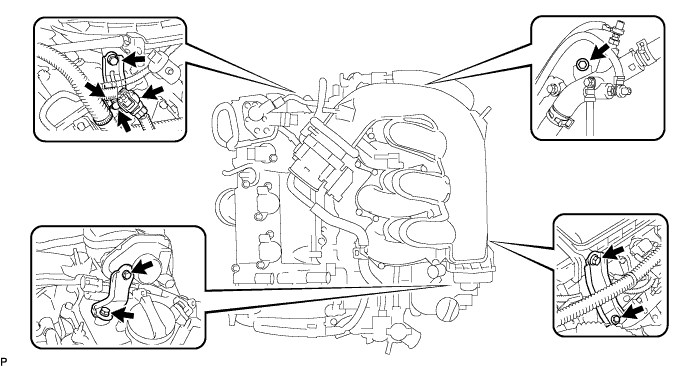

Connect the 2 wire harness clamps.

Connect the water hose joint with the bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Install the intake manifold stay with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Connect the wire harness clamp to the intake air surge tank.

Connect the IACV connector.

Connect the SCV position sensor connector.

Connect the throttle motor connector.

| 7. CONNECT FUEL MAIN TUBE |

|

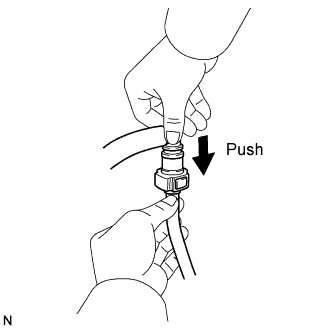

- NOTICE:

- Before installing the fuel main tube's connector to the fuel main pipe, check the connector for damage and foreign matter.

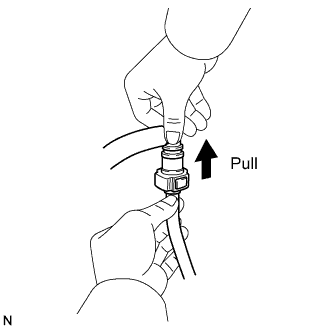

Connect the connector to the fuel main pipe. Push the two parts together firmly until a "click" sound is heard. Then attach the lock claws to the connector by pushing down on the connector cover.

Check that the connector and fuel main pipe are securely connected by trying to pull them apart.

|

Install the fuel pipe clamp.

|

| 8. CONNECT VENTILATION HOSE |

|

Connect the ventilation hose to the ventilation valve.

| 9. CONNECT UNION TO CHECK VALVE HOSE |

|

Connect the hose to the surge tank.

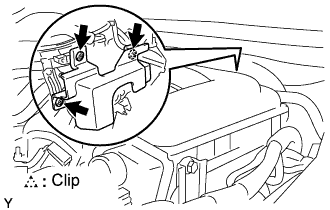

| 10. INSTALL ENGINE REAR COVER |

|

Install the engine rear cover with the 3 clips.

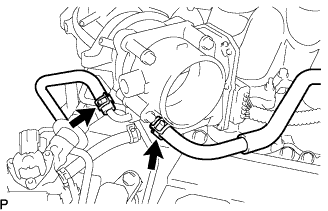

| 11. CONNECT HEATER WATER INLET HOSE |

|

Connect the hose to the pipe.

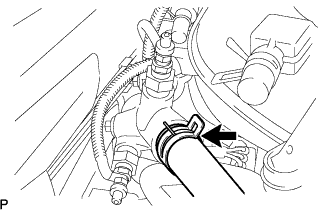

| 12. CONNECT WATER BY-PASS HOSE |

|

Connect the 2 water by-pass hoses to the throttle body.

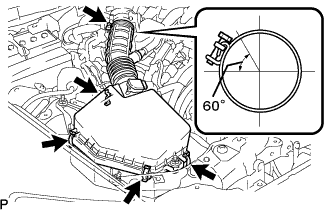

| 13. INSTALL AIR CLEANER CAP WITH AIR CLEANER HOSE |

|

Install the air cleaner cap with air cleaner hose assembly with the 4 clamps and hose clamp.

- HINT:

- Be sure to install the air cleaner assembly so that the screw part of the hose clamp is as shown in the illustration.

Install the VSV (for EVAP )to the air cleaner hose.

|

Connect the MAF meter connector and clamp to the air cleaner.

|

| 14. CONNECT NO. 2 VENTILATION HOSE |

|

Connect the ventilation hose to the cylinder head cover with the clamp.

| 15. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 16. ADD ENGINE COOLANT |

- NOTICE:

- Before adding engine coolant, turn the A/C switch OFF.

Tighten all the plugs and fill the radiator with TOYOTA Super Long Life Coolant (SLLC).

- Torque:

- 12.7 N*m{130 kgf*cm, 9 ft.*lbf} for cylinder block drain cock plug

Add engine coolant.

- Specified capacity:

- 9.1 liters (9.6 US qts, 8.0 lmp. qts)

- NOTICE:

- When pressing the radiator hose:

- Wear protective gloves.

- Be careful as the radiator hose is hot.

- Keep your hands away from the radiator fan.

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

- Please contact your TOYOTA dealer for further details.

- The thermostat open timing can be confirmed by pressing the inlet radiator hose by hand, and checking when the engine coolant starts to flow inside the hose.

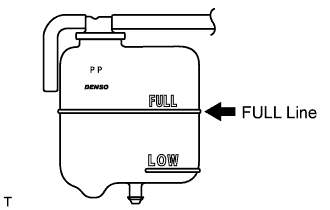

Slowly pour coolant into the radiator reservoir until it reaches the FULL line.

Press the inlet and outlet radiator hoses several times by hand, and then check the level of the coolant.

If the coolant level is low, add coolant.

Install the radiator cap and reservoir cap.

Bleed air from the cooling system.

- NOTICE:

- Before starting the engine to warm up the engine, turn the A/C switch OFF.

Warm up the engine until the thermostat opens. While the thermostat is open, circulate the coolant for several minutes.

- HINT:

- The thermostat open timing can be confirmed by pressing the inlet radiator hose by hand, and checking when the engine coolant starts to flow inside the hose.

- NOTICE:

- When pressing the radiator hoses:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan.

Maintain the engine speed at 2,000 to 2,500 rpm.

Press the inlet and outlet radiator hoses several times by hand to bleed air.

- NOTICE:

- When pressing the radiator hoses:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan.

Stop the engine, and wait until the engine coolant cools down to ambient temperature.

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Check the coolant level in the radiator reservoir.

If the coolant level is low, add SLLC to the radiator reservoir FULL line.

|

| 17. CHECK FOR ENGINE COOLANT LEAKAGE |

|

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Fill the radiator with coolant and attach a radiator cap tester.

Warm up the engine.

Using a radiator cap tester, increase the pressure inside the radiator to 118 kPa (1.2 kgf/cm, 17 psi), and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator and water pump for leaks. If no external leaks are found, check the heater core, cylinder block and head.

| 18. CHECK FOR FUEL LEAKAGE |

Start the engine, and check that there are no fuel leaks after performing maintenance anywhere on the system.

| 19. CHECK FOR ENGINE OIL LEAKS |

Start the engine, and check that there are no oil leaks after performing maintenance.

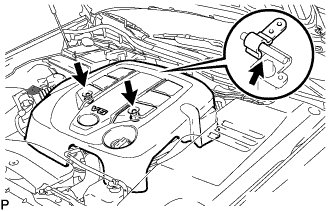

| 20. INSTALL V-BANK COVER |

|

Install the V-bank cover with the 2 nuts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

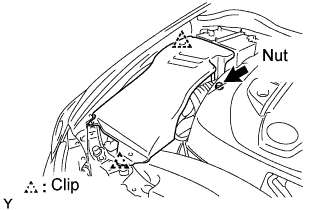

| 21. INSTALL ENGINE ROOM SIDE COVER RH |

|

Install the side cover with the 2 clips and nut.

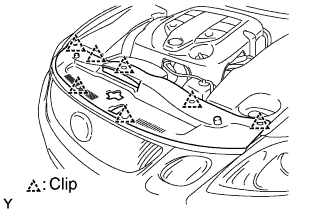

| 22. INSTALL COOL AIR INTAKE DUCT SEAL |

|

Install the intake duct seal with the 7 clips.

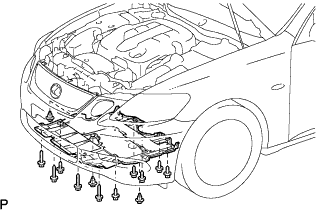

| 23. INSTALL ENGINE UNDER COVER |

Install the under cover with the 10 bolts and 3 clips.

|

| 24. PERFORM INITIALIZATION |

Perform initialization (Click here).

- NOTICE:

- Certain systems need to be initialized after disconnecting and reconnecting the cable from the negative (-) battery terminal.

| 25. WARM UP ENGINE |

After the engine is warmed up, check that the maintained parts operate normally.