Engine. Lexus Gs430, Gs300. Uzs190 Grs190

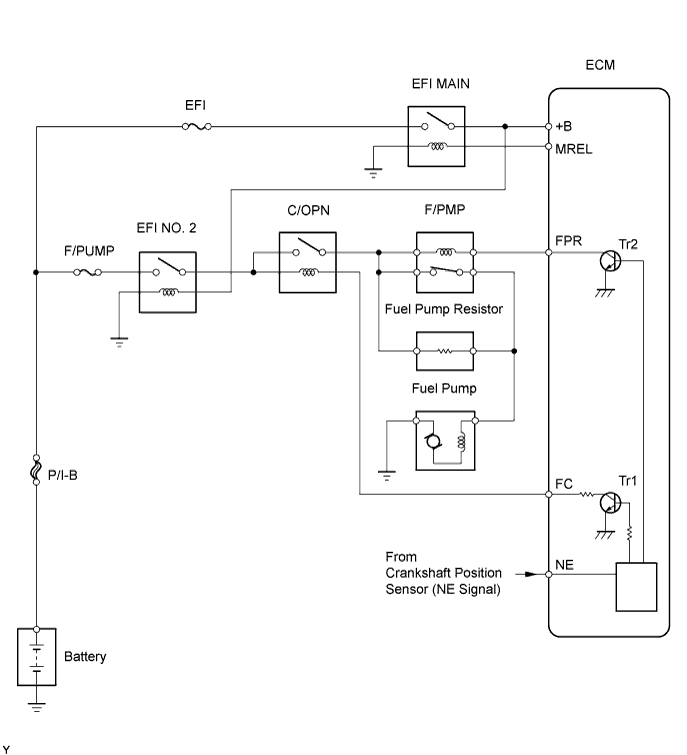

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK FUEL PUMP OPERATION

PERFORM ACTIVE TEST (OPERATE C/OPN RELAY)

INSPECT ECM POWER SOURCE CIRCUIT

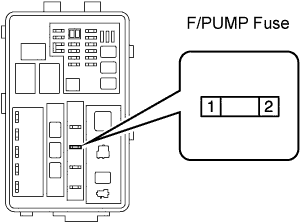

INSPECT FUSE (F/PUMP)

INSPECT INTEGRATION RELAY (Marking: EFI NO. 2)

INSPECT INTEGRATION RELAY (Marking: C/OPN)

CHECK ECM (FC VOLTAGE)

INSPECT RELAY (Marking: F/PMP)

INSPECT FUEL PUMP

CHECK WIRE HARNESS (FUEL PUMP - F/PMP RELAY, FUEL PUMP - BODY GROUND)

CHECK WIRE HARNESS (INTEGRATION RELAY - FUEL PUMP RELAY)

INSPECT RELAY (Marking: F/PMP)

INSPECT FUEL PUMP RESISTOR

CHECK WIRE HARNESS (F/PMP RELAY - FUEL PUMP RESISTOR)

SFI SYSTEM - Fuel Pump Control Circuit |

DESCRIPTION

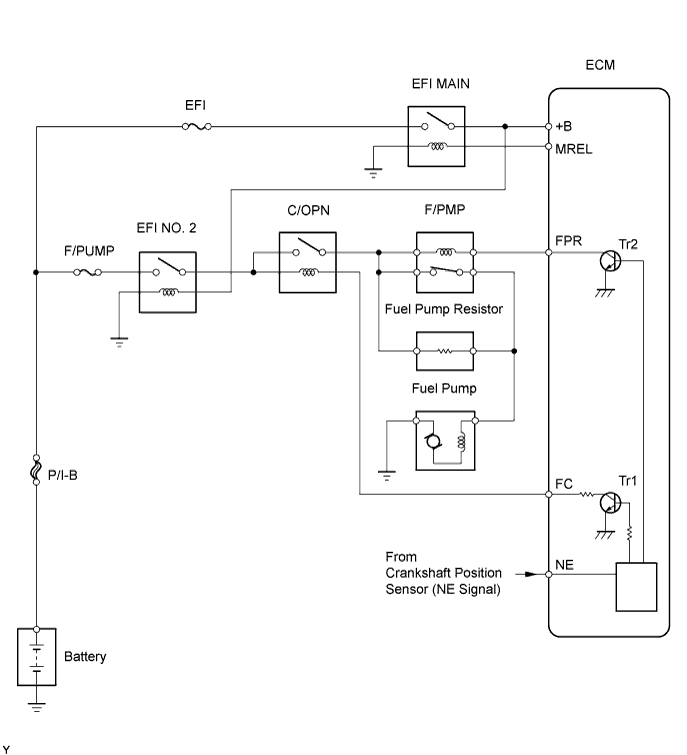

When the engine is cranked, a signal is sent from the power source control ECU's STSW terminal to the ECM's STSW terminal. Then voltage travels from the ECM's STAR terminal through the park/neutral position switch to the STARTER relay coil. The STAR terminal also sends a signal to the STA terminal. When the STA signal and NE signal are input to the ECM, the ECM interior's Tr1 turns on, which causes power to be supplied to the C/OPN relay coil (C/OPN on). As a result, the F/PMP relay actuates, which causes the fuel pump to operate. If the engine is operating and NE signals are being output, the ECM interior's Tr1 is on (C/OPN on), and the fuel pump will continue operating. The fuel pump has a high and low speed setting. When the engine is starting or operating with a heavy load, the ECM interior's Tr2 turns on to actuate the F/PMP relay so that the fuel pump operates at the high speed setting. When the engine is idling or operating with a light load, the Tr2 turns off, and current flows through the fuel pump resistor to the fuel pump so that the fuel pump operates at the low speed setting.

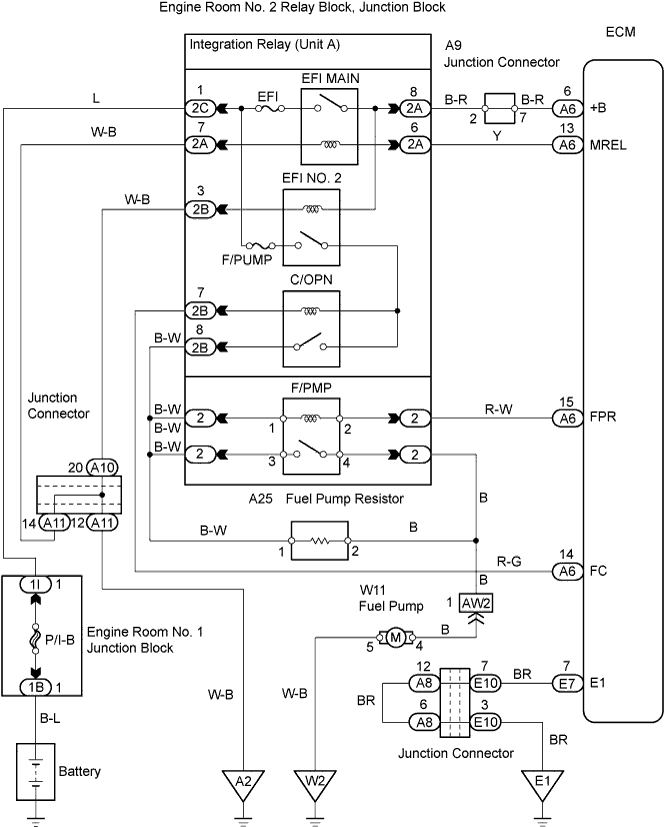

WIRING DIAGRAM

This troubleshooting procedure is based on the premise that the engine is started. If the engine is not started, proceed to the problem symptoms table (Click here).

INSPECTION PROCEDURE

| 1.CHECK FUEL PUMP OPERATION |

Check if there is pressure in the fuel inlet hose.

- HINT:

- If there is fuel pressure, you will hear the sound of fuel flowing.

| 2.PERFORM ACTIVE TEST (OPERATE C/OPN RELAY) |

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG) and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / Active Test / Active the Fuel Pump / Speed.

Check the relay operation while operating it using the intelligent tester.

- OK:

- Operating noise can be heard from the relay.

| 3.INSPECT ECM POWER SOURCE CIRCUIT |

| | CHECK ENGINE TO DETERMINE CAUSE OF LOW COMPRESSION |

|

|

Remove the F/PUMP fuse from the engine room No. 2 junction block.

Measure the resistance of the fuse.

- Standard resistance:

- Below 1 Ω

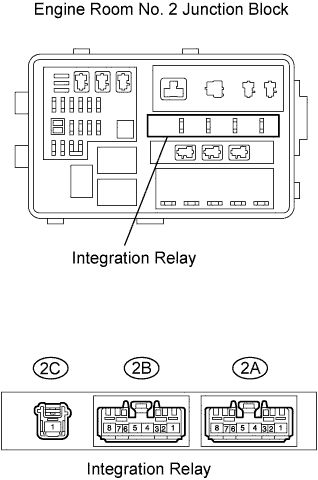

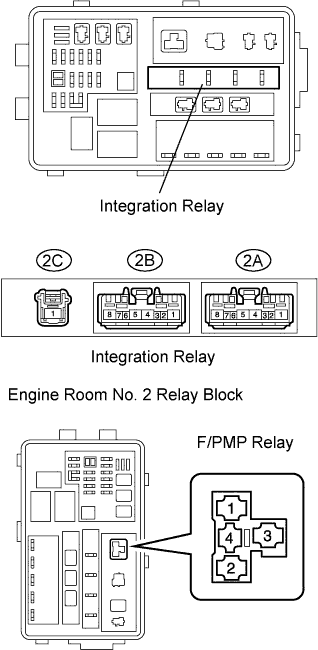

| 5.INSPECT INTEGRATION RELAY (Marking: EFI NO. 2) |

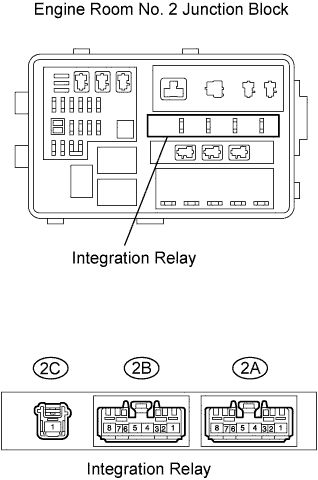

Remove the integration relay from the engine room No. 2 junction block.

Measure the resistance of the EFI NO. 2 relay.

- Standard resistance:

Terminal Connections

| Specified Condition

|

2B-8 - 2C-1

| 10 kΩ or higher

|

2B-8 - 2C-1

| Below 1 Ω

(when battery voltage is applied to terminals 2A-8 and 2B-3)

|

| | REPLACE INTEGRATION RELAY |

|

|

| 6.INSPECT INTEGRATION RELAY (Marking: C/OPN) |

Remove the integration relay from the engine room No. 2 junction block.

Measure the resistance of the C/OPN relay.

- Standard resistance:

Terminal Connections

| Specified Condition

|

2B-8 - 2C-1

| 10 kΩ or higher

|

2B-8 - 2C-1

| Below 1 Ω

(when battery voltage is applied to terminals 2B-7 and 2C-1)

|

| | REPLACE INTEGRATION RELAY |

|

|

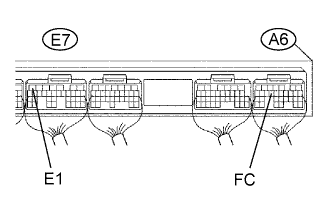

Turn the engine switch on (IG).

Measure the voltage of the ECM connector.

- Standard voltage:

Tester Connection

| Specified Condition

|

A6-14 (FC) - E7-7 (E1)

| 9 to 14 V

|

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS AND CONNECTOR (ECM - C/OPN RELAY) |

|

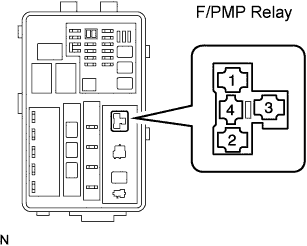

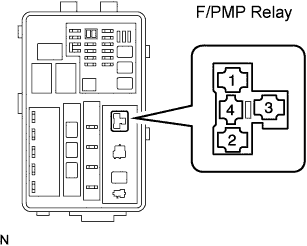

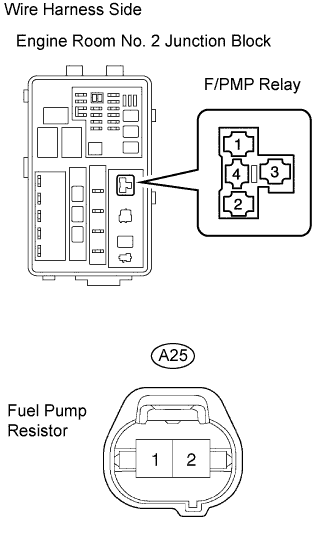

| 8.INSPECT RELAY (Marking: F/PMP) |

Remove the F/PMP relay from the engine room No. 2 relay block.

Measure the resistance of the relay.

- Standard resistance:

Tester Connection

| Specified Condition

|

3 - 4

| Below 1 Ω

|

3 - 4

| 10 kΩ or more

(when battery voltage is applied to terminals 1 and 2)

|

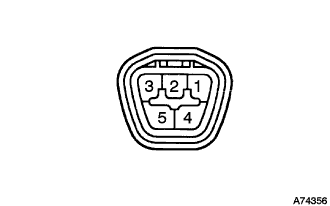

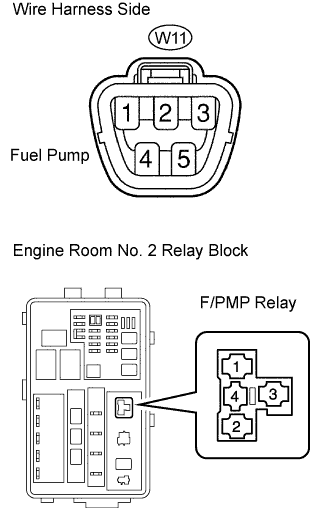

Check the resistance of the fuel pump.

Measure the resistance between terminals 4 and 5.

- Standard resistance:

- 0.2 to 3.0 Ω at 20°C (68°F)

Check operation of the fuel pump.

Apply battery voltage to both terminals. Check that the pump operates.

- NOTICE:

- These tests must be done quickly (within 10 seconds) to prevent the coil from burning out.

- Keep fuel pump as far away from the battery as possible.

- Always turn the voltage on and off on the battery side, not the fuel pump side.

| 10.CHECK WIRE HARNESS (FUEL PUMP - F/PMP RELAY, FUEL PUMP - BODY GROUND) |

Check the wire harness between the fuel pump and F/PMP relay.

Disconnect the W11 fuel pump connector.

Remove the F/PMP relay from the engine room No. 2 relay block.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

W11-4 - Relay block F/PMP relay terminal 4

| Below 1 Ω

|

W11-4 or relay block F/PMP relay terminal 4 - Body ground

| 10 kΩ or higher

|

Check the wire harness between the fuel pump and body ground.

Disconnect the W11 fuel pump connector.

Measure the resistance of the wire harness side connector.

- Standard resistance:

Tester Connection

| Specified Condition

|

W11-4 - Body ground

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| 11.CHECK WIRE HARNESS (INTEGRATION RELAY - FUEL PUMP RELAY) |

Remove the integration relay from the engine room No. 2 junction block.

Remove the F/PMP relay from the engine room No. 2 relay block.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

2B-8 - Relay block F/PMP relay terminal 1

| Below 1 Ω

|

2B-8 - Relay block F/PMP relay terminal 3

| Below 1 Ω

|

2B-8 or relay block F/PMP relay terminal 1 - Body ground

| 10 kΩ or higher

|

2B-8 or relay block F/PMP relay terminal 3 - Body ground

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| OK |

|

|

|

| REPLACE INTEGRATION RELAY |

|

| 12.INSPECT RELAY (Marking: F/PMP) |

Remove the F/PMP relay from the engine room No. 2 relay block.

Measure the resistance of the relay.

- Standard resistance:

Tester Connection

| Specified Condition

|

3 - 4

| Below 1 Ω

|

3 - 4

| 10 kΩ or higher

(when battery voltage is applied to terminals 1 and 2)

|

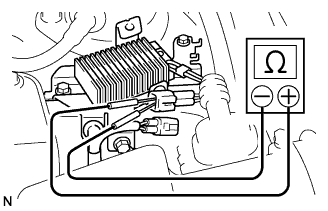

| 13.INSPECT FUEL PUMP RESISTOR |

Measure the resistance of the fuel pump resistor.

- Standard resistance:

- 0.30 to 0.34 Ω at 20°C (68°F)

| | REPLACE FUEL PUMP RESISTOR |

|

|

| 14.CHECK WIRE HARNESS (F/PMP RELAY - FUEL PUMP RESISTOR) |

Remove the F/PMP relay from the engine room No. 2 relay block.

Disconnect the A25 fuel pump resistor connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

Relay block F/PMP relay terminal 4 - A25-2

| Below 1 Ω

|

Relay block F/PMP relay terminal 3 - A25-1

| Below 1 Ω

|

Relay block F/PMP relay terminal 4 or A25-2 - Body ground

| 10 kΩ or higher

|

Relay block F/PMP relay terminal 3 or A25-1 - Body ground

| 10 kΩ or higher

|

| | PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS TABLE |

|

|

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS AND CONNECTOR |

|