Dtc B1418/18 Exhaust Gas Sensor Circuit

DESCRIPTION

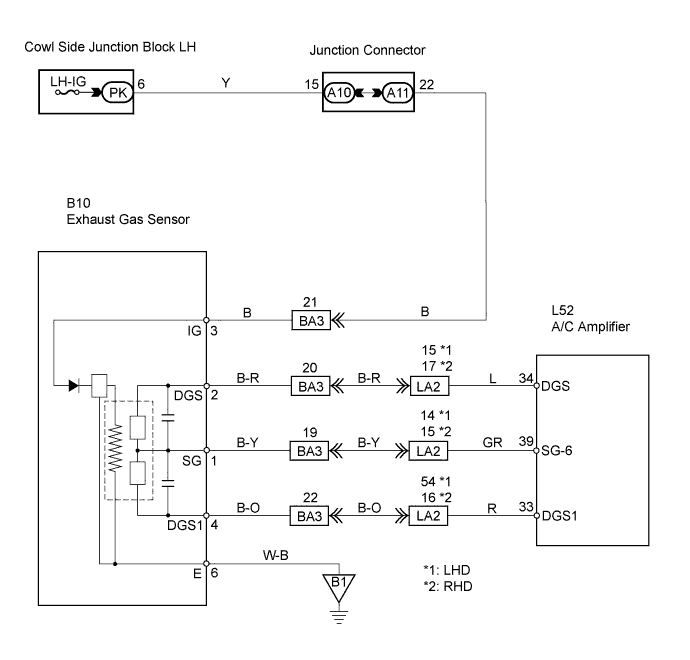

WIRING DIAGRAM

INSPECTION PROCEDURE

INSPECT FUSE (LH-IG)

READ VALUE OF INTELLIGENT TESTER

CHECK WIRE HARNESS (EXHAUST GAS SENSOR - BODY GROUND)

CHECK WIRE HARNESS (EXHAUST GAS SENSOR - BATTERY)

INSPECT EXHAUST GAS SENSOR

CHECK WIRE HARNESS (EXHAUST GAS SENSOR - A/C AMPLIFIER)

DTC B1418/18 Exhaust Gas Sensor Circuit |

DESCRIPTION

The exhaust gas sensor, which is installed on the front of the condenser, automatically changes to FRESH, FRESH / RECIRCULATION, or RECIRCULATION. The exhaust gas sensor detects CO and HC in emission gas and transmits signals to the A/C amplifier.DTC No.

| DTC Detection Condition

| Trouble Area

|

B1418/18

| Open or short in emission gas sensor circuit (HC, CO)

| - Exhaust gas sensor (emission gas sensor)

- Harness and connector between exhaust gas sensor (emission gas sensor) and A/C amplifier

- A/C amplifier

|

WIRING DIAGRAM

INSPECTION PROCEDURE

Remove the LH-IG fuse from the cowl side junction block LH.

Measure the resistance of the fuse.

- Standard resistance:

Tester Item

| Condition

| Specified Condition

|

LH-IG fuse

| Always

| Below 1 Ω

|

| | CHECK FOR SHORT IN ALL HARNESSES AND COMPONENTS CONNECTED TO FUSE |

|

|

| 2.READ VALUE OF INTELLIGENT TESTER |

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG) and push the intelligent tester main switch on.

Select the item below in the Data List, and read the display on the intelligent tester.

A/C amplifierItem

| Measure Item / Display

(Range)

| Normal Condition

| Diagnostic Note

|

Emission Gas Sensor

(Emiss Gas Sens)

| Emission gas /

Min.: 0 V, Max.: 255 V

| Increases as the gas amount increases

| -

|

- OK:

- The display is as specified in the normal condition.

Result:NG

| A

|

OK (Checking from the PROBLEM SYMPTOMS TABLE)

| B

|

OK (Checking from the DTC)

| C

|

| | PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

| | REPLACE AIR CONDITIONING AMPLIFIER |

|

|

| 3.CHECK WIRE HARNESS (EXHAUST GAS SENSOR - BODY GROUND) |

Disconnect the B10 exhaust gas sensor connector.

Measure the resistance of the wire harness side connector.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

B10-6 (E) - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| 4.CHECK WIRE HARNESS (EXHAUST GAS SENSOR - BATTERY) |

Disconnect the B10 exhaust gas sensor connector.

Measure the resistance of the wire harness side connector.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

B10-3 (IG) - Body ground

| Engine switch on (IG)

| 10 to 14 V

|

Engine switch off

| Below 1 V

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

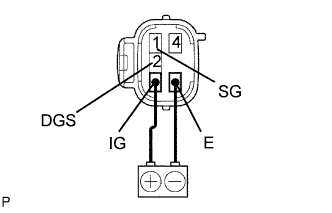

| 5.INSPECT EXHAUST GAS SENSOR |

Remove the exhaust gas sensor.

After applying battery voltage between terminals 3 (IG) and 6 (E) for more than 30 seconds, measure the resistance between terminals 1 (SG) and 2 (DGS).

Measure the resistance of the sensor.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

1 (SG) - 2 (DGS)

| 10 to 35°C

(50 to 95°F)

| 5 to 100 kΩ

|

- HINT:

- When the sensor is exposed to the exhaust gas, the resistance decreases.

| | REPLACE EXHAUST GAS SENSOR |

|

|

| 6.CHECK WIRE HARNESS (EXHAUST GAS SENSOR - A/C AMPLIFIER) |

Disconnect the B10 exhaust gas sensor connector.

Disconnect the L52 A/C amplifier connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

B10-1 (SG) - L52-39 (SG-6)

| Always

| Below 1 Ω

|

B10-2 (DGS) - L52-34 (DGS)

| Always

| Below 1 Ω

|

L52-39 (SG-6) - Body ground

| Always

| 10 kΩ or higher

|

L52-34 (DGS) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| OK |

|

|

|

| REPLACE AIR CONDITIONING AMPLIFIER |

|