Wiper And Washer System Headlight Cleaner Switch Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK COWL SIDE JUNCTION BLOCK RH (HDLO SIGNAL)

INSPECT ENGINE ROOM NO. 2 JUNCTION BLOCK (FRONT WINDOW WASHER SIGNAL)

CHECK WIRE HARNESS (HEADLIGHT CLEANER CONTROL RELAY - BATTERY AND BODY GROUND)

INSPECT COWL SIDE JUNCTION BLOCK RH

CHECK WIRE HARNESS (HEADLIGHT CLEANER CONTROL RELAY - COWL SIDE JUNCTION BLOCK RH)

CHECK WIRE HARNESS (HEADLIGHT CLEANER CONTROL RELAY - ENGINE ROOM JUNCTION BLOCK)

INSPECT INTEGRATION CONTROL & PANEL ASSEMBLY (HEADLIGHT CLEANER SWITCH)

WIPER AND WASHER SYSTEM - Headlight Cleaner Switch Circuit |

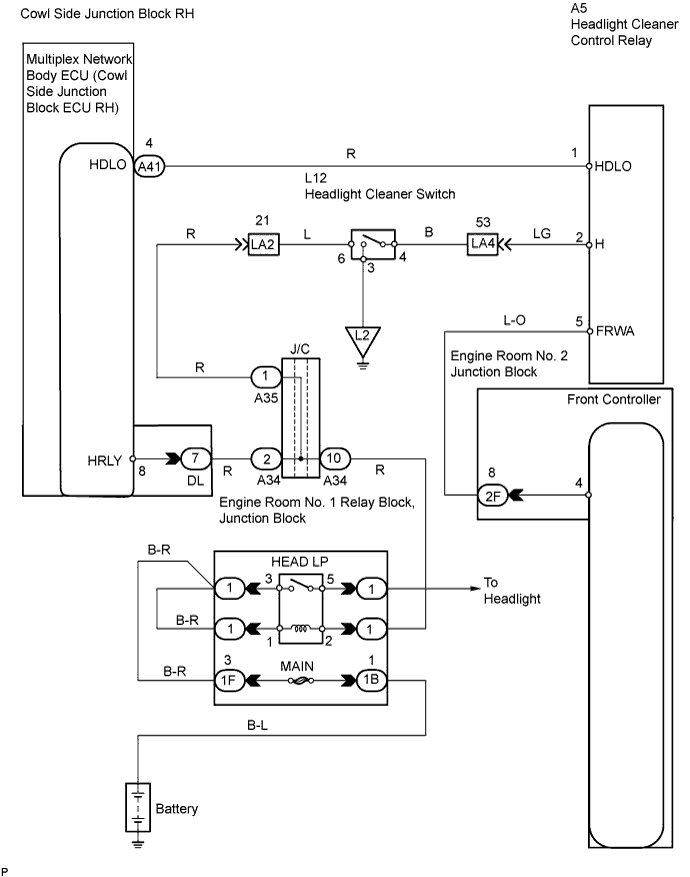

DESCRIPTION

This circuit detects the conditions of the headlight cleaner switch.The headlight cleaner control relay receives the following signals:- Headlight cleaner switch signal

- Headlight operating signal

- Daytime running light operating signal

- Front washer motor operating signal

WIRING DIAGRAM

INSPECTION PROCEDURE

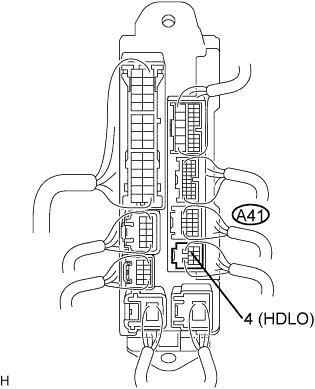

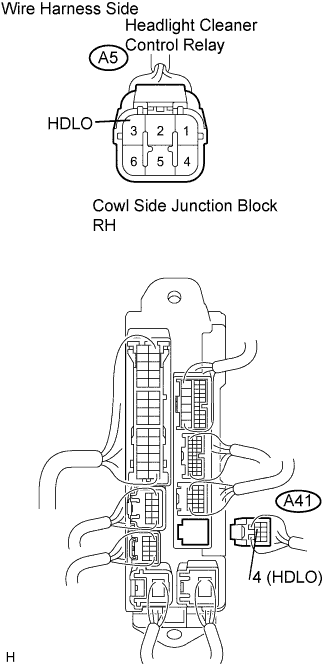

| 1.CHECK COWL SIDE JUNCTION BLOCK RH (HDLO SIGNAL) |

Measure the voltage of the connector.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

A41-4 (HDLO) - Body ground

| Engine switch on (IG) and light control switch OFF

| 10 to 14 V

|

A41-4 (HDLO) - Body ground

| Engine switch on (IG) and light control switch in HEAD position

| Below 1 V

|

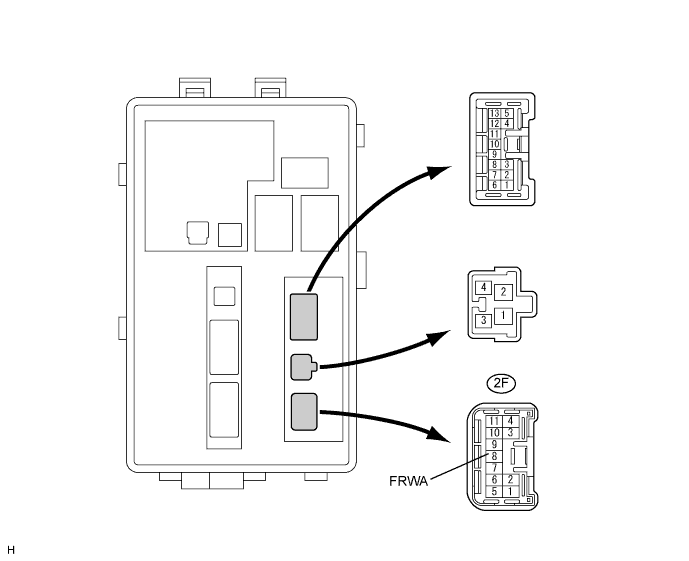

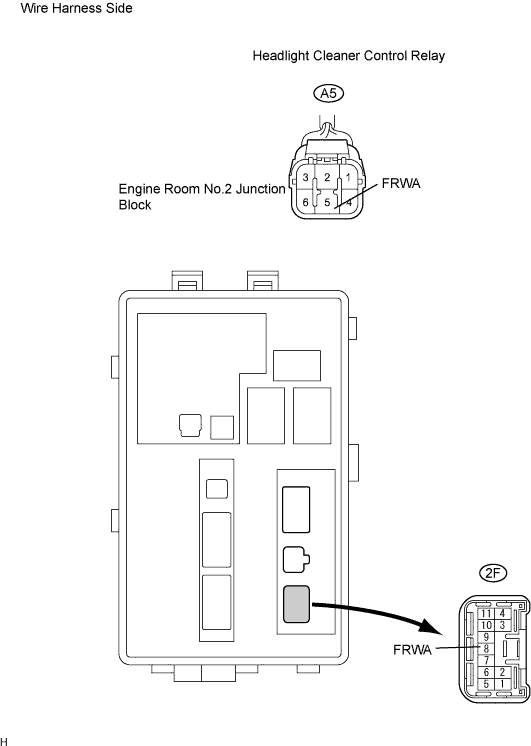

| 2.INSPECT ENGINE ROOM NO. 2 JUNCTION BLOCK (FRONT WINDOW WASHER SIGNAL) |

Measure the voltage of the connector.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

2F-8 (FRWA) - Body ground

| Engine switch on (IG) and front washer is stopped

| 10 to 14 V

|

2F-8 (FRWA) - Body ground

| Engine switch on (IG) and front washer is operated

| Below 1 V

|

| 3.CHECK WIRE HARNESS (HEADLIGHT CLEANER CONTROL RELAY - BATTERY AND BODY GROUND) |

Disconnect the A5 headlight cleaner control relay connector.

Measure the resistance of the connector.

- Standard resistance :

Tester Connection

| Condition

| Specified Condition

|

A5-2 (H) - Body ground

| Headlight cleaner switch OFF (not pushed)

| 10 kΩ or higher

|

A5-2 (H) - Body ground

| Headlight cleaner switch ON (pushed)

| Below 1 Ω

|

| OK |

|

|

|

| PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE |

|

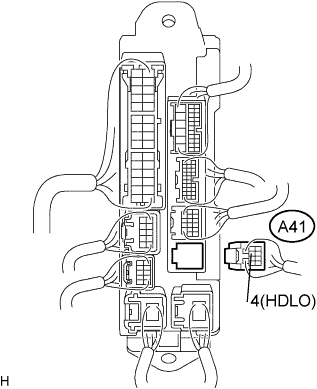

| 4.INSPECT COWL SIDE JUNCTION BLOCK RH |

Disconnect the A41 cowl side junction block RH connector.

Measure the voltage of the connector.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

A41-4 (HDLO) - Body ground

| Engine switch off

| Below 1 V

|

A41-4 (HDLO) - Body ground

| Engine switch on (IG)

| 10 to 14 V

|

| OK |

|

|

|

| REPLACE COWL SIDE JUNCTION BLOCK RH |

|

| 5.CHECK WIRE HARNESS (HEADLIGHT CLEANER CONTROL RELAY - COWL SIDE JUNCTION BLOCK RH) |

Disconnect the A5 relay connector.

Disconnect the A41 junction block connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

A5-3 (HDLO) - A41-4 (HDLO)

| Always

| Below 1 Ω

|

A5-3 (HDLO) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| OK |

|

|

|

| REPLACE HEADLIGHT CLEANER CONTROL RELAY |

|

| 6.CHECK WIRE HARNESS (HEADLIGHT CLEANER CONTROL RELAY - ENGINE ROOM JUNCTION BLOCK) |

Disconnect the A5 relay connector.

Disconnect the 2F junction block connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

A5-5 (FRWA) - F2-8 (FRWA)

| Always

| Below 1 Ω

|

A5-5 (FRWA) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| OK |

|

|

|

| REPLACE ENGINE ROOM NO. 2 JUNCTION BLOCK (FRONT CONTROLLER) |

|

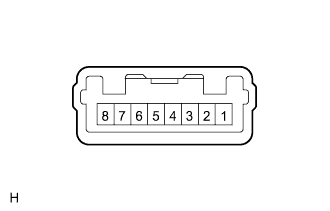

| 7.INSPECT INTEGRATION CONTROL & PANEL ASSEMBLY (HEADLIGHT CLEANER SWITCH) |

Remove the integration control & panel assembly.

Measure the resistance of the connector.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

3 - 4

| Integration control & panel ON (not pushed)

| 10 kΩ or higher

|

3 - 4

| Integration control & panel OFF (pushed)

| Below 1 Ω

|

| | REPLACE INTEGRATION CONTROL & PANEL ASSEMBLY (HEADLIGHT CLEANER SWITCH) |

|

|

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS AND CONNECTOR |

|