Emission Control System -- On-Vehicle Inspection |

| 1. VISUALLY INSPECT HOSES, CONNECTORS AND GASKETS |

|

Check that there are no cracks, leaks or damage.

- NOTICE:

- Detachment or other problems with the engine oil dipstick, filler cap, PCV hose and other components may cause the engine to run improperly. Disconnection, looseness or cracks in the parts of the air induction system between the throttle body and cylinder head will allow air suction and cause an engine failure or engine malfunctions.

| 2. INSPECT A/F COMPENSATION SYSTEM |

|

- HINT:

- This system can be checked using the intelligent tester.

- Select the following menu items: Powertrain / Engine / Data List / O2S B1 S2 (O2S B2 S2).

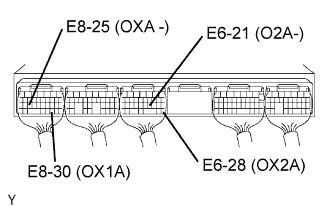

Connect the intelligent tester to terminals E8-25 (OXA-) and E8-30 (OX1A) of the ECM.

Connect the intelligent tester to terminals E6-21 (O2A-) and E6-28 (OX2A) of the ECM.

- NOTICE:

- Connect the tester leads to the back of the connectors. The connectors should not be disconnected from the ECM.

Warm up the heated oxygen sensor by running the engine at 2,500 rpm for approximately 2 minutes.

Check that the voltage changes between 0 V and 1 V with the engine speed at 2,500 rpm.

- Standard condition:

- The voltage changes 8 times or more in 10 seconds.

- NOTICE:

- Check the voltage immediately after warming up the heated oxygen sensor.

- If a change of voltage could not be confirmed, warm up the heated oxygen sensor again.

| 3. INSPECT FUEL CUT OFF RPM |

Increase the engine speed to 3,000 rpm.

Use a sound scope to check the injector operation noise.

- Standard condition:

- When the throttle lever is released, the injector operation noise stops momentarily but starts again.

| 4. INSPECT LINE AND CONNECTORS |

Visually check for loose connections, sharp bends or damage.

| 5. INSPECT FUEL TANK ASSEMBLY |

Visually check for deformation, cracks or fuel leakage.

| 6. INSPECT EMISSION CONTROL SYSTEM |

|

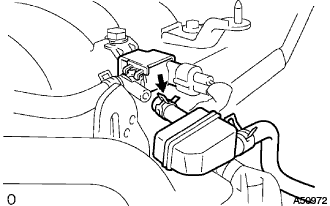

Start the engine. Disconnect the vacuum hose as shown in the illustration.

Set the intelligent tester to ACTIVE TEST mode and select VSV (for EVAP). Check that a vacuum occurs at the VSV port.

Exit ACTIVE TEST mode and reconnect the vacuum hose.

Set the intelligent tester to ECU DATA MONITOR mode and select VSV (for EVAP). Check the VSV (for EVAP) operation.

Warm up the engine and drive the vehicle. Check that the VSV (for EVAP) changes from OFF to ON.

| 7. INSPECT FUEL CUTOFF VALVE AND FILL CHECK VALVE |

Disconnect the vent line hose from the fuel tank.

Connect the pressure gauge to the fuel tank.

Fill the fuel tank with fuel.

Apply pressure of 4 kPa (41 gf/cm2, 0.58 psi) to the vent port of the fuel tank.

- HINT:

- It is necessary to check the amount of fuel in the fuel tank. When the fuel tank is full, the float valve of the fill check valve is closed and no air can pass through.

Remove the fuel tank cap, and check that the pressure drops.

If the pressure does not drop, replace the fuel tank assembly.

Reconnect the vent line hose to the fuel tank.

| 8. INSPECT AIR INLET LINE |

Disconnect the air inlet line hose from the charcoal canister.

Check that air can flow freely into the air inlet line.

If air cannot flow freely into the air inlet line, repair or replace it.

Reconnect the air inlet line hose to the charcoal canister.