Rear Propeller Shaft Assembly (For 3Uz-Fe) -- Installation |

| 1. INSTALL REAR PROPELLER SHAFT ASSEMBLY |

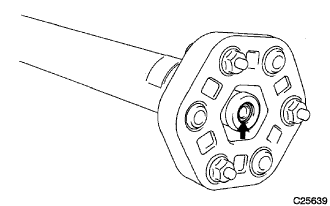

Apply grease to the flexible coupling centering bushings.

- Grease:

- Molybdenum disulphide lithium base, NLGI No.2

|

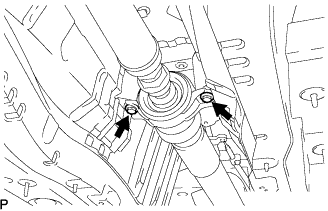

Install the propeller shaft from the vehicle's rear and connect the transmission and differential.

- NOTICE:

- Support the center support bearing by hand so that the transmission and intermediate shaft, and propeller shaft and differential, remain in a straight line.

Temporarily install the 2 center support bearing set bolts with the adjusting washers.

- HINT:

- Use the adjusting washers which were removed.

|

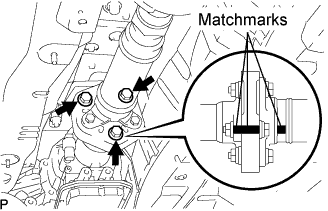

Align the matchmarks on the transmission companion flange and flexible coupling.

|

Temporarily install the 3 bolts, washers and nuts.

- HINT:

- The bolts should be installed from the propeller shaft side.

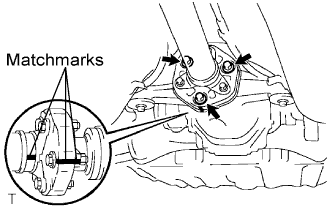

Align the matchmarks on the differential companion flange and flexible coupling.

|

Temporarily install the 3 bolts, washers and nuts.

- HINT:

- The bolts should be installed from the propeller shaft side.

Tighten the 6 nuts.

- Torque:

- 79 N*m{805 kgf*cm, 58 ft.*lbf}

- NOTICE:

- Be careful not to damage the flexible coupling centering bushing.

| 2. FULLY TIGHTEN CENTER SUPPORT BEARING ASSEMBLY NO.1 |

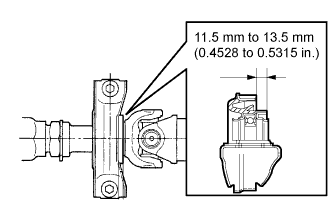

Adjust the dimension between the edge surface of the center support bearing and the edge surface of the cushion to 11.5 to 13.5 mm (0.4528 to 0.5315 in.) respectively as shown in illustration.

|

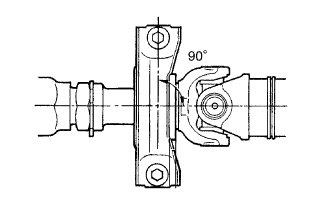

Check that the center line of the bracket is at right angles to the shaft axial direction.

|

Tighten the 2 bolts.

- Torque:

- 49 N*m{500 kgf*cm, 36 ft.*lbf}

|

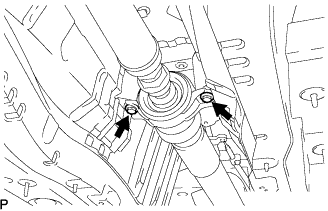

Using SST, tighten the adjusting nut.

- SST

- 09922-10010

- Torque:

- 69 N*m{700 kgf*cm, 51 ft.*lbf}

- HINT:

- Use a torque wrench with a fulcrum length of 34.5 cm (13.6 in.).

|

| 3. INSPECT AND ADJUST NO. 2 AND NO. 3 JOINT ANGLE |

Stabilize the propeller shaft and differential.

Turn the propeller shaft several times by hand to stabilize the center support bearing.

Check the No.2 and No.3 joint angles.

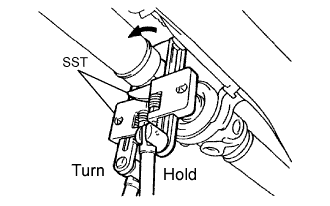

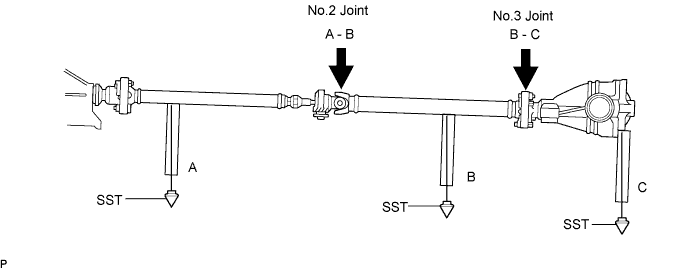

Using SST, measure the installation angle of the intermediate shaft and propeller shaft.

- SST

- 09370-50010

- HINT:

- The SST should be set directly underneath the shaft.

Using SST, measure the installation angle of the differential.

- SST

- 09370-50010

- HINT:

- Measure the installation angle by placing the SST in the positions, shown in the illustration.

Calculate the No.2 joint angle.

- No.2 joint angle:

- A - B = 0°11' to 1°11'

- A:

- Intermediate shaft installation angle

- B:

- Propeller shaft installation angle

Calculate the No.3 joint angle.

- No.3 joint angle:

- B - C = 0°53' to 1°53'

- B:

- Propeller shaft installation angle

- C:

- Differential installation angle

- HINT:

- If the measured angle is not within the specified range, adjust it with the center support bearing washers.

Adjust the No.2 joint angle.

Select the center support bearing washers for adjustment.

Adjustment washer thickness mm (in.) 2 (0.0787) 4.5 (0.1772) 6.5 (0.2559) 9.0 (0.3543) 11 (0.4331) - NOTICE:

- The 2 washers should be of the same thickness.

| 4. INSTALL FRONT FLOOR HEAT INSULATOR NO.1 |

Install the heat insulator No.1 with the 4 nuts.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 5. INSTALL EXHAUST PIPE ASSEMBLY FRONT |

| 6. CHECK FOR EXHAUST GAS LEAKS |