READ OUTPUT DTC (RECORD STORED DTC AND FREEZE FRAME DATA (PROCEDURE 1))

CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P1603)

TAKE SNAPSHOT DURING IDLING (PROCEDURE 3)

DETERMINE CAUSE OF PROBLEM (CHECK FREEZE FRAME DATA AND SNAPSHOT)

DTC P1603 Engine Stall History |

DESCRIPTION

After starting the engine, this DTC is stored when the engine stops without the ignition switch being operated.Using the intelligent tester, the conditions present when the DTC was stored can be confirmed by referring to the freeze frame data. Freeze frame data records engine conditions when a malfunction occurs. This information can be useful when troubleshooting.

It is necessary to check if the vehicle has ran out of fuel before performing troubleshooting, as this DTC is also stored when the engine stalls due to running out of fuel.

| DTC Detection Drive Pattern | DTC Detection Condition | Trouble Area |

| - | 2 seconds or more elapse after starting the engine, and the engine running, the engine stops for 0.5 seconds or more without the ignition switch being operated (for Manual Transmission: Fuel pressure drops to 10000 kPa or less and fuel injection is stopped) (1 trip detection logic) |

|

| DTC No. | Data List |

| P1603 |

|

INSPECTION PROCEDURE

| Fuel system |

The following malfunctions may be present in the fuel system.

Problem with injector assemblies.

Problem with fuel supply pump assembly.

Air in fuel pipe.

Fuel filter element sub-assembly clog.

| Engine assembly |

The following malfunctions may be present in the engine assembly.

Insufficient compression.

- HINT:

- In contrast to normal malfunction diagnosis for components, circuits and systems, DTC P1603 is used to determine the malfunctioning area from the problem symptoms and freeze frame data when the user mentions problems such as engine stall.

As the DTC can be stored as a result of certain user actions, even if the DTC is output, if the customer makes no mention of problems, clear the DTC without performing any troubleshooting and return the vehicle to the customer. - If any other DTCs are output, perform troubleshooting for those DTCs first.

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

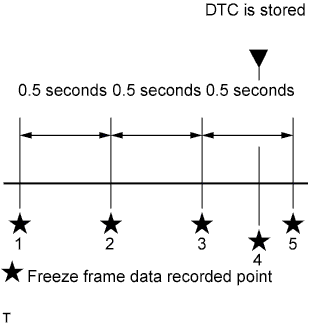

- When confirming the freeze frame data, be sure to check all 5 sets of freeze frame data.

The fourth set of freeze frame data is the data recorded when the DTC is stored.

| 1.READ OUTPUT DTC (RECORD STORED DTC AND FREEZE FRAME DATA (PROCEDURE 1)) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON and turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Record the stored DTC and freeze frame data.

- HINT:

- This freeze frame data shows the actual engine conditions when engine stall trouble occurred.

| NEXT | |

| 2.CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P1603) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON and turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

Result Result Proceed to P1603 is output A P1603 and other DTCs are output B - HINT:

- If any DTCs other than DTC P1603 are output, troubleshoot those DTCs first.

|

| ||||

| A | |

| 3.TAKE SNAPSHOT DURING IDLING (PROCEDURE 3) |

Connect the intelligent tester to the DLC3.

Start the engine and turn the tester on.

Warm up the engine (engine coolant temperature is 70°C (158°F) or higher).

Enter the following menus: Powertrain / Engine and ECT / Data List / All Data.

Take a snapshot when idling with no load after the engine is warmed up and when the problem is occurring.

Text in Illustration *1 Snapshot Button - HINT:

- A snapshot can be used to compare vehicle data from the time of the malfunction to normal data and is very useful for troubleshooting.

- Graphs can be displayed by transferring the stored snapshot data from the tester to a PC. Intelligent Viewer must be installed on the PC.

- The shift lever should be in neutral and the A/C switch and all accessory switches should be off.

- If rough idling occurs when the A/C switch is on, take another snapshot with the A/C switch on.

- Take a snapshot when the problem is occurring, such as when the engine is cold. However, if the problem does not reoccur, it is acceptable to only take a snapshot after the engine is warmed up.

|

| NEXT | |

| 4.DETERMINE CAUSE OF PROBLEM (CHECK FREEZE FRAME DATA AND SNAPSHOT) |

Determine the cause of the problem based on the freeze frame data recorded in procedure 1 and the Data List values recorded when idling the engine in procedure 3.

Battery Voltage Judgment of Data List Values Problem Cause Normal Condition Diagnosis Note "Battery Voltage" in freeze frame data is below 6 V Engine starting trouble may have occurred because battery is fully depleted During cranking: 6 V or higher The battery may be fully depleted or the battery terminals may be loose. Fuel Press Judgment of Data List Values Problem Cause Normal Condition Diagnosis Note "Fuel Press" in freeze frame data is below 25000 kPa (254.9 kgf/cm2, 3626 psi) Problem supplying fuel to fuel supply pump assembly (low pressure side) - Ran out of fuel, air in fuel, fuel frozen (in this case, values of "Fuel Temperature" and "Coolant Temp" in freeze frame data are low)

- Fuel filter element sub-assembly clog, fuel line clog (low pressure side) or fuel leak

- Feed pump (in fuel supply pump assembly) malfunctioning

- Fuel supply pump assembly (suction control valve operation malfunction)

- Common rail assembly

When in a stable condition such as when the engine is idling after being warmed up, the fuel pressure is within +/-5000 kPa of the target fuel pressure - HINT:

- In order to maintain the injection amount before an engine stall, the target common rail pressure is increased drastically. At this time, Fuel Press may not follow correctly, but this is normal behavior and not a malfunction.

If "Fuel Press" is 10000 kPa (102.0 kgf/cm2, 1451 psi) or less, fuel injection control is stopped. - HINT:

- Refer to Engine Difficult to Start or Stalling for the inspection procedure (HILUX_TGN26 RM000000TJ508ZX_02_0116.html).

Injection Feedback Val #1(to #4) Judgment of Data List Values Problem Cause Normal Condition Diagnosis Note "Injection Feedback Val #1 (to #4)" in freeze frame data is not +3.0 mm3/st or less Injector assembly malfunction or compression problem Less than +3.0 mm3/st If an injector assembly is malfunctioning, even though the engine starts, idling is rough. - HINT:

- Refer to Engine Difficult to Start or Stalling for the inspection procedure (HILUX_TGN26 RM000000TJ508ZX_02_0090.html).

"Injection Feedback Val #1 (to #4)" in Data List is not +3.0 mm3/st or less when idling Injection Volume Judgment of Data List Values Problem Cause Normal Condition Diagnosis Note "Injection Volume" in Data List is more than 12 mm3/st and "Injection Feedback Val #1 (to #4)" is within range of 3.0 mm3/st when idling after warming up engine Injector assemblies of all cylinders malfunctioning - - HINT:

- Refer to Engine Difficult to Start or Stalling for the inspection procedure (HILUX_TGN26 RM000000TJ508ZX_02_0090.html).

Immobiliser Fuel Cut History Judgment of Data List Values Problem Cause Normal Condition Diagnosis Note "Immobiliser Fuel Cut History" in freeze frame data is OFF to ON Fuel injection has stopped due to engine immobiliser system. - HINT:

- "Main Injection Period" in freeze frame data is 0 μs

OFF - Inspect engine immobiliser system.

- Inspection looseness in battery terminal.

- Inspect connection condition of ECM power supply system wiring.

- HINT:

- Perform the next inspection if there are no problems with the above items.

- Ran out of fuel, air in fuel, fuel frozen (in this case, values of "Fuel Temperature" and "Coolant Temp" in freeze frame data are low)

| NEXT | ||

| ||