Clutch Unit -- Inspection |

| 1. INSPECT CLUTCH DISC ASSEMBLY |

Using a vernier caliper, measure the rivet head depth.

- Minimum rivet head depth:

- 0.3 mm (0.0118 in.)

|

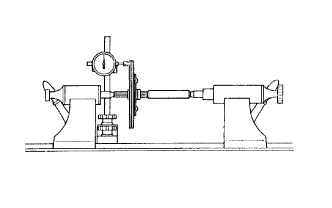

Using a dial indicator, check the disc runout.

- Maximum runout:

- 0.8 mm (0.0314 in.)

- NOTICE:

- Be sure to measure on the correct side of the clutch disc.

|

| 2. INSPECT CLUTCH COVER ASSEMBLY |

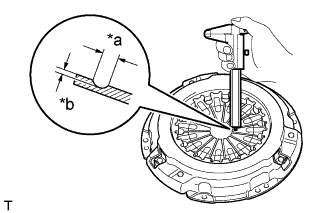

Using a vernier caliper, measure the depth and width of the worn areas of the diaphragm spring.

Text in Illustration *a Width *b Depth - Maximum width:

- 6.0 mm (0.236 in.)

- Maximum depth:

- 0.35 mm (0.0137 in.)

|

| 3. INSPECT FLYWHEEL SUB-ASSEMBLY |

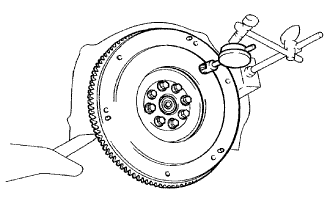

Using a dial indicator, measure the flywheel runout.

- Maximum runout:

- 0.1 mm (0.00393 in.)

|

| 4. INSPECT CLUTCH RELEASE BEARING ASSEMBLY |

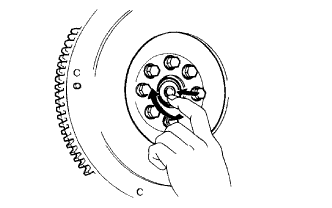

Turn the bearing by hand while applying force in the axial direction and check that the bearing rotates smoothly.

If the bearing sticks or a considerable amount of resistance is felt, replace the release bearing.- HINT:

- The bearing is permanently lubricated and requires no cleaning or lubrication.

|

| 5. INSPECT INPUT SHAFT FRONT BEARING |

Turn the bearing by hand while applying rotational force and check that the bearing rotates smoothly.

If the bearing sticks or a considerable amount of resistance is felt, replace the input shaft front bearing.- HINT:

- The bearing is permanently lubricated and requires no cleaning or lubrication.

|

| 6. REPLACE INPUT SHAFT FRONT BEARING |

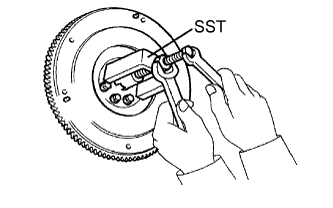

Remove any 2 diametrically opposite bolts.

Using SST, remove the input shaft front bearing.

- SST

- 09303-35011

|

Using SST and a hammer, tap in a new bearing.

- SST

- 09304-12012

- HINT:

- After installing the bearing to the crankshaft, make sure that it rotates smoothly.

|

Apply adhesive to 2 or 3 threads of the bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

for TR Engine series:

Install the 2 bolts.

- Torque:

- 27 N*m{270 kgf*cm, 20 ft.*lbf}

- HINT:

- The mounting bolts are tightened in 2 progressive steps.

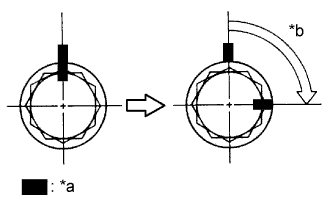

Mark the mounting bolts with paint.

Text in Illustration *a Paint Mark *b 90° Retighten the mounting bolts by 90°.

Check that the paint marks are now at a 90° angle to the original marked position.

for 1KD-FTV, 2KD-FTV:

Apply adhesive to 2 or 3 threads of the bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the 2 bolts.

- Torque:

- 178 N*m{1815 kgf*cm, 131 ft.*lbf}