Cylinder Head -- Inspection |

| 1. INSPECT CYLINDER HEAD SUB-ASSEMBLY |

Using a precision straightedge and feeler gauge, measure the warpage of the surfaces that contact the cylinder block and manifolds.

- Maximum warpage:

- 0.05 mm (0.00197 in.)

If the warpage is more than the maximum, replace the cylinder head.Text in Illustration *a Cylinder Head Lower Side *b Intake Manifold Side *c Exhaust Manifold Side

|

Using a dye penetrant, check the intake ports, exhaust ports and cylinder head surface for cracks.

If cracked, replace the cylinder head.

| 2. INSPECT INNER COMPRESSION SPRING |

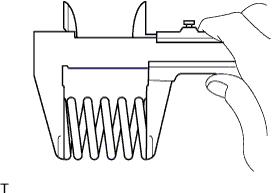

Using a vernier caliper, measure the free length of the inner compression spring.

- Standard free length:

- 48.53 mm (1.91 in.)

|

Using a steel square, measure the deviation of the inner compression spring.

- Maximum deviation:

- 1.5 mm (0.0591 in.)

- Maximum angle:

- 2°

If the deviation is more than the maximum, replace the spring.Text in Illustration *1 Deviation

|

| 3. INSPECT INTAKE VALVE |

Using a vernier caliper, measure the overall length of the valve.

- Standard overall length:

- 106.26 mm (4.18 in.)

- Minimum overall length:

- 105.96 mm (4.17 in.)

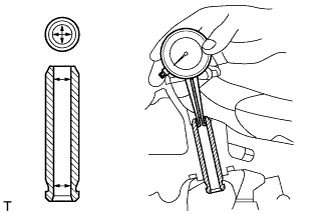

Using a micrometer, measure the diameter of the valve stem.

- Standard valve stem diameter:

- 5.470 to 5.485 mm (0.215 to 0.216 in.)

Using a vernier caliper, measure the valve head margin thickness.

- Standard margin thickness:

- 1.05 to 1.45 mm (0.0413 to 0.0571 in.)

- Minimum margin thickness:

- 0.50 mm (0.0197 in.)

If the margin thickness is less than the minimum, replace the intake valve.Text in Illustration *1 Margin Thickness

|

| 4. INSPECT EXHAUST VALVE |

Using a vernier caliper, measure the overall length of the valve.

- Standard overall length:

- 106.74 mm (4.20 in.)

- Minimum overall length:

- 106.44 mm (4.19 in.)

Using a micrometer, measure the diameter of the valve stem.

- Standard valve stem diameter:

- 5.465 to 5.480 mm (0.215 to 0.216 in.)

Using a vernier caliper, measure the valve head margin thickness.

- Standard margin thickness:

- 1.2 to 1.6 mm (0.0472 to 0.0630 in.)

- Minimum margin thickness:

- 0.50 mm (0.0197 in.)

If the margin thickness is less than the minimum, replace the exhaust valve.Text in Illustration *1 Margin Thickness

|

| 5. INSPECT VALVE SEAT |

Apply a light coat of Prussian blue to the valve face.

Lightly press the valve face against the valve seat.

- HINT:

- Do not rotate the valve while pressing the valve against the valve seat.

Check the valve face and valve seat by using the following procedure.

Check that Prussian blue appears around the entire valve face. If not, replace the valve.

Check that Prussian blue appears around the entire valve seat. If so, the guide and valve face are concentric. If not, resurface the valve seat.

Check that the valve seat contacts the middle of the valve face with the width between 1.1 and 1.4 mm (0.0433 and 0.0551 in.).

Text in Illustration *1 Width

|

| 6. INSPECT CAMSHAFT THRUST CLEARANCE |

Install the camshafts (HILUX_TGN26 RM000000YMY01EX.html).

|

Using a dial indicator, measure the thrust clearance while moving the camshaft back and forth.

- Standard thrust clearance:

- 0.10 to 0.24 mm (0.00394 to 0.00945 in.)

- Maximum thrust clearance:

- 0.26 mm (0.0102 in.)

| 7. INSPECT CAMSHAFT OIL CLEARANCE |

Clean the bearing caps and camshaft journals.

Place the camshafts on the cylinder head.

Lay a strip of Plastigage across each of the camshaft journals.

Text in Illustration *1 Plastigage

|

Install the bearing caps (HILUX_TGN26 RM000000YMY01EX_01_0005.html).

- NOTICE:

- Do not turn the camshafts.

Remove the bearing caps (HILUX_TGN26 RM000000YN001CX_01_0008.html).

Measure the Plastigage at its widest point.

- Standard Oil Clearance:

Item Specified Condition No. 1 journal 0.035 to 0.072 mm (0.00138 to 0.00283 in.) Other journals 0.025 to 0.062 mm (0.000984 to 0.00244 in.)

- Maximum oil clearance:

- 0.08 mm (0.00315 in.)

If the oil clearance is more than the maximum, replace the camshaft. If necessary, replace the cylinder head sub-assembly.Text in Illustration *1 Plastigage

|

Completely remove the Plastigage.

| 8. INSPECT VALVE GUIDE BUSH OIL CLEARANCE |

Using a caliper gauge, measure the inside diameter of the guide bush.

- Standard bush inside diameter:

- 5.51 to 5.53 mm (0.217 to 0.218 in.)

|

Subtract the valve stem diameter measurement from the guide bush inside diameter measurement.

- Standard Oil Clearance:

Item Specified Condition Intake 0.025 to 0.060 mm (0.000984 to 0.00236 in.) Exhaust 0.030 to 0.065 mm (0.00118 to 0.00256 in.)

- Maximum Oil Clearance:

Item Specified Condition Intake 0.08 mm (0.00315 in.) Exhaust 0.10 mm (0.00397 in.)