DESCRIPTION

INSPECTION PROCEDURE

CONFIRM CONDITION IN WHICH NOISE OCCURRED

CONFIRM NOISE CUSTOMER MENTIONED (PROCEDURE 2)

CHECK INTAKE SYSTEM

CONFIRM NOISE SOURCE (FORM TURBOCHARGER OR NOT)

CONFIRM THE NOISE TYPE

PERFORM ALIGNMENT OF EXHAUST PIPE AND CONFIRM THE NOISE

CHECK FOR NOISE FROM SOURCE OTHER THAN TURBOCHARGER (PROCEDURE 7)

REPLACE THE PARTS DETECTED IN PROCEDURE 7

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

EXPLAIN TO THE CUSTOMER THAT THE NOISE IS NORMAL

ECD SYSTEM (for DPF) - Turbocharger Noise |

DESCRIPTION

- HINT:

- Turbocharger noise is classified into 2 types. One is whistling noise, and the other is whining noise. When troubleshooting, the type of noise should be determined first.

DescriptionNoise Type

| Noise Description

| Main Trouble Area

|

Whistling noise

| The volume and pitch of this noise are proportional to turbocharger speed or engine speed. Therefore, the noise level will become more obvious when engine speed increases.

| - Turbocharger (e.g. shaft imbalance)

- Balance shaft gear

- Transmission gear

- Intake air system leakage

- Intake air system breakage

|

Whining noise

| This noise has a lower pitch than whistling noise. It generally occurs in the engine speed range of 1500 to 2500 rpm, and has a relatively constant pitch, independent of engine speed and vehicle speed.

| Turbocharger

- HINT:

- Example: Vibration of turbocharger is transferred to exhaust pipe which causes resonation and noise.

- Example: Vibration of turbocharger is transferred through exhaust pipe to vehicle body (floor) which then vibrates causing noise.

|

| Faults and Symptoms of Diesel Engine Components |

Turbocharger SystemMain fault

| Turbocharger turbine shaft imbalance

|

Symptoms

| High-pitched whistling noise

- HINT:

- The pitch and volume change in proportion to the turbocharger speed.

|

Intake SystemMain fault

| Leakage

|

Symptoms

| Leak flow noise

|

Balance Shaft GearSymptoms

| Gear noise

- HINT:

- The pitch and volume change in proportion to the engine speed.

|

Transmission GearSymptoms

| Gear noise

- HINT:

- The pitch and volume change in proportion to the transmission gear speed.

|

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses of circuits related to this system before performing the following inspection procedure.

- After replacing the ECM, the new ECM needs registration (HILUX_TGN26 RM0000012XK058X.html) and initialization (HILUX_TGN26 RM000000TIN056X.html).

- After replacing the fuel supply pump assembly, the ECM needs initialization (HILUX_TGN26 RM000000TIN056X.html).

- After replacing an injector assembly, the ECM needs registration (HILUX_TGN26 RM0000012XK058X.html).

| 1.CONFIRM CONDITION IN WHICH NOISE OCCURRED |

Confirm with the customer the conditions in which the noise occurred.

- HINT:

- To clearly understand the conditions in which the noise occurred, the items in the table below are useful.

Item

| Note

|

Engine speed

| Engine speed range

|

Vehicle speed

| Vehicle speed range

|

Transmission gear

| Which gear?

|

Accelerator pedal position

| During acceleration or deceleration?

|

Temperature

| - Ambient temperature

- Engine temperature (cold, warmed up, etc.)

|

Road conditions

| - City or highway driving

- Uphill or downhill

|

Noise level

| - Did the noise occur suddenly, or build gradually?

- Has the noise gradually been getting louder?

|

Other symptoms

| - Lack of power

- High fuel consumption, etc.

|

Noise recognition

| What made the customer determine the noise to be abnormal?

|

| 2.CONFIRM NOISE CUSTOMER MENTIONED (PROCEDURE 2) |

Check for the noise described by the customer.

- HINT:

- If a noise is heard, make sure that the noise matches the noise described by the customer.

ResultResult

| Proceed to

|

Obvious abnormal noise matching noise described by customer is confirmed

| A

|

Obvious abnormal noise matching noise described by customer is not confirmed

| B

|

Check for air leakage between the air cleaner and turbocharger, and between the turbocharger and intake manifold.

- HINT:

- Check for disconnected or improperly connected hoses, and gaps between hoses and parts.

- Check for foreign matter between the air cleaner and turbocharger.

| | REPAIR OR REPLACE MALFUNCTIONING PARTS |

|

|

| 4.CONFIRM NOISE SOURCE (FORM TURBOCHARGER OR NOT) |

Connect the intelligent tester to the DLC3.

Start the engine and warm it up.

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the VN Turbo Open.

Perform the Active Test under the conditions* from the time the noise occurred described by the customer and compare the noise to the noise heard when not performing the Active Test and check if the noise is reduced.

- HINT:

- *: Some examples of conditions are idling, racing the engine and driving at full throttle.

ResultResult

| Proceed to

|

The noise is reduced (or disappears)

| A

|

The noise is the same as in Procedure 2 (The noise does not change)

| B

|

- HINT:

- By performing Activate the VN Turbo Open Active Test, the variable nozzle of the turbocharger becomes fully open regardless of the engine condition, and the turbocharger speed does not increase.

- If the turbocharger is the cause of the noise, the noise will be reduced when Activate the VN Turbo Open Active Test is performed because turbocharger speed does not increase.

Check whether the noise can be heard even when the engine speed is more than 3000 rpm, and whether the noise gradually gets louder as the engine speed increases.

- HINT:

- If so, the noise is likely to be whistling noise. If not, the noise is likely to be whining noise.

ResultResult

| Proceed to

|

Yes (The noise is likely to be whistling noise)

| A

|

No (The noise is likely to be whining noise)

| B

|

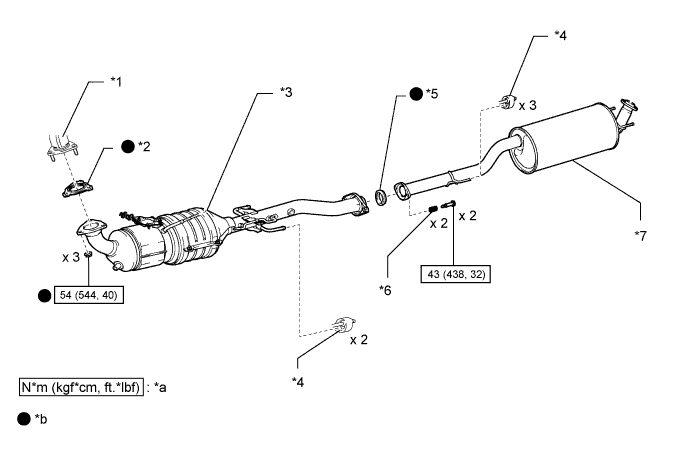

| 6.PERFORM ALIGNMENT OF EXHAUST PIPE AND CONFIRM THE NOISE |

Disconnect the front exhaust pipe assembly at the ball joint and from each exhaust pipe support, and then realign the exhaust pipe and reconnect it to each exhaust pipe support and at the ball joint (HILUX_TGN26 RM00000456800CX.html).

Text in Illustration*1

| Outlet Pipe

| *2

| Gasket

|

*3

| Front Exhaust Pipe Assembly

| *4

| Exhaust Pipe Support

|

*5

| Gasket (Ball Joint)

| *6

| Compression Spring

|

*7

| Center Exhaust Pipe Assembly

| -

| -

|

*a

| Specified Torque

| *b

| Non-reusable Part

|

Confirm whether the noise problem is solved or not.

- HINT:

- The alignment of the exhaust pipe affects whining noise.

ResultResult

| Proceed to

|

The noise problem is solved

| A

|

The noise problem remains

| B

|

| 7.CHECK FOR NOISE FROM SOURCE OTHER THAN TURBOCHARGER (PROCEDURE 7) |

Check for the noise source.

Start the engine

Race the engine and check if the noise reduces at the same time the engine speed decreases.

- HINT:

- If the noise reduces at the same time the engine speed decreases, it is gear noise.

- If the noise reduces a short time after the engine speed decreases, it is turbocharger noise.

| 8.REPLACE THE PARTS DETECTED IN PROCEDURE 7 |

Replace the parts detected in Procedure 7 as the noise source.

| 9.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Check whether the noise problem has been successfully solved.

| 10.EXPLAIN TO THE CUSTOMER THAT THE NOISE IS NORMAL |

Explain to the customer that the noise the customer mentioned is not abnormal.

- HINT:

- To help the customer understand, test driving another car with the customer may be helpful.