DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK FOR ANY OTHER DTCS OUTPUT (RECORD STORED DTC AND FREEZE FRAME DATA)

CHECK AIR INTAKE SYSTEM

REPAIR OR REPLACE AIR INTAKE SYSTEM

CHECK TURBOCHARGER SUB-ASSEMBLY (DC MOTOR OPERATION)

PERFORM ACTIVE TEST USING INTELLIGENT TESTER (ACTIVATE THE EGR VALVE CLOSE)

READ VALUE USING INTELLIGENT TESTER (TARGET EGR POSITION AND ACTUAL EGR VALVE POS.)

CHECK ELECTRIC EGR CONTROL VALVE ASSEMBLY (CHECK VACUUM)

REMOVE DEPOSIT (ELECTRIC EGR CONTROL VALVE ASSEMBLY)

REPAIR OR REPLACE VACUUM HOSE

REPLACE EGR COOLER

READ VALUE USING INTELLIGENT TESTER (INJECTION VOLUME)

REPLACE INJECTOR ASSEMBLIES OF ALL CYLINDERS

BLEED AIR FROM FUEL SYSTEM

REGISTER INJECTOR COMPENSATION CODE AND PERFORM PILOT QUANTITY LEARNING

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

CHECK HARNESS AND CONNECTOR (TURBO MOTOR DRIVER - TURBOCHARGER SUB-ASSEMBLY)

DTC P1251 Turbocharger / Supercharger Overboost Condition (Too High) |

DESCRIPTION

- HINT:

- Refer to DTC P0046 (HILUX_TGN26 RM000002NCM01MX_06.html).

P1251DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

Vehicle being driven

| Boost pressure is higher than the threshold* for 0.5 seconds. (1 trip detection logic).

| - Turbocharger sub-assembly

- VN turbo link stuck malfunction

- Extremely low battery voltage (P0560 stored simultaneously)

- Intake system

- Exhaust system

- Electric EGR control valve assembly

- EGR cooler

- Injector assembly

- Diesel throttle body assembly

- ECM

|

- HINT:

- *: This value changes based on engine speed, atmospheric pressure and the engine coolant temperature (the value is generally between 177 and 250 kPa).

Related Data ListDTC No.

| Data List

|

P1251

| - MAP

- Target Booster Pressure

- MAF

- Target EGR Position

- Actual EGR Valve Pos.

- VN Turbo Command

- Atmosphere Pressure

|

- HINT:

- If DTC P1251 is stored due to the VN turbo vane being stuck closed, the following symptoms may appear:

- Vehicle surge when driving with full load

- Sudden lack of power due to power being limited

WIRING DIAGRAM

- Refer to DTC P0046 (HILUX_TGN26 RM000002NCM01MX_07.html).

- Refer to DTC P2563 (HILUX_TGN26 RM000002PPN036X_02.html).

INSPECTION PROCEDURE

- NOTICE:

- After replacing the ECM, the new ECM needs registration (HILUX_TGN26 RM0000012XK05BX.html) and initialization (HILUX_TGN26 RM000000TIN04CX.html).

- HINT:

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

| 1.CHECK FOR ANY OTHER DTCS OUTPUT (RECORD STORED DTC AND FREEZE FRAME DATA) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON and turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

- HINT:

- Record the stored DTC and Freeze Frame Data.

- Be sure to carefully examine "MAP" and "Target Booster Pressure" in the freeze frame data.

ResultResult

| Proceed to

|

P1251 is output

| A

|

P1251 and other DTCs are output

| B

|

- HINT:

- DC motor-related DTCs: P0046 (HILUX_TGN26 RM000002NCM01MX_06.html), P0047 and P0048 (HILUX_TGN26 RM000002PPL03YX_01.html).

- Nozzle vane position sensor-related DTCs: P2563, P2564, P2565, P2588 and P2589 (HILUX_TGN26 RM000002PPN036X_01.html).

| 2.CHECK AIR INTAKE SYSTEM |

Check if the hoses between the air cleaner and turbocharger, and turbocharger and intake manifold are damaged or disconnected.

ResultResult

| Proceed to

|

Hoses or pipes are damaged or disconnected

| A

|

No hoses or pipes are damaged or disconnected

| B

|

- HINT:

- Be sure to check if the hoses and pipes between the air cleaner and compressor are disconnected as disconnection of a hose or pipe can cause overboost. Also, check the high pressure hoses for disconnection due to overboost.

- Check for disconnection of the exhaust pipes.

- Using your hand, check whether the pipes and hoses in the intake system are securely connected.

- Check for any modifications in the intake system made by the user.

| 3.REPAIR OR REPLACE AIR INTAKE SYSTEM |

Repair or replace the malfunctioning part in the air intake system.

| 4.CHECK TURBOCHARGER SUB-ASSEMBLY (DC MOTOR OPERATION) |

Check the turbocharger sub-assembly (HILUX_TGN26 RM0000014VF02WX_01_0006.html).

- HINT:

- Check the movement of the actuator rod when the ignition switch is turned from ON to off.

| 5.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (ACTIVATE THE EGR VALVE CLOSE) |

Connect the intelligent tester to the DLC3.

Start the engine and warm it up, and make sure the A/C switch and all accessory switches are off.

Turn the ignition switch off. Wait for 30 seconds, and then restart the engine.

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / MAF.

Read the MAF value displayed on the tester while the engine is idling.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the EGR Valve Close.

Read the MAF value when the EGR valve is closed using the Active Test function.

- HINT:

- If idling continues for 15 minutes or more, the EGR valve target opening angle becomes 0% (EGR valve fully closed). As this makes diagnosis impossible, it becomes necessary to drive the vehicle or to restart the engine.

- Before performing the diagnosis, confirm that the EGR valve target opening angle is not 0%.

- When "Coolant Temp" is 75°C (167°F) or higher during idling, the exhaust gas flows through the EGR cooler. If MAF does not change when the EGR is cut even though the EGR valve is operating normally, the EGR cooler may be clogged.

- When idling while warming up the engine, the actuator operates and the EGR cooler is bypassed. However, if the connector of the VSV for the EGR cooler is disconnected, the EGR cooler is not bypassed and it is possible to check how clogged the EGR cooler is.

ResultActive Test

| Result

| Proceed to

|

Activate the EGR Valve Close:

Off (Open) to On (Closed)

| MAF value does not change

| A

|

MAF value changes

| B

|

- NOTICE:

- As the measured values may differ from those shown below due to factors such as differences in measuring environments and changes in vehicle condition due to aging, do not use these values to determine whether the vehicle is malfunctioning or not.

- HINT:

- The problem may be a temporary one, due to the entry of deposits or foreign matter. Check that there are no deposits or foreign matter in the electric vacuum regulating valve assembly or mass air flow meter.

- Reference:

EGR Valve Condition (Opening)

| Measuring Condition

| MAF (Reference)

|

Open (55%)

| - Atmosphere pressure: 101 kPa

- Intake air temperature: 30°C (86°F)

- Engine coolant temperature: 88°C (190°F)

| 3.0 to 9.0 gm/s

|

Closed (0%)

| 15 to 22 gm/s

|

| 6.READ VALUE USING INTELLIGENT TESTER (TARGET EGR POSITION AND ACTUAL EGR VALVE POS.) |

Check the change in the values of "Target EGR Position" and "Actual EGR Valve Pos." in the Data List from the time when the "Activate The EGR valve Close" Active Test was performed in the previous step.

ResultResult

| Proceed to

|

Even though "Target EGR Position" indicated that the system was commanding the valve to open, "Actual EGR Valve Pos." remained near 0% and did not change

| A

|

Other than above ("Actual EGR Valve Pos." changed according to the EGR valve open/close commands of the Active Test)

| B

|

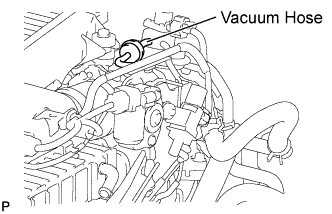

| 7.CHECK ELECTRIC EGR CONTROL VALVE ASSEMBLY (CHECK VACUUM) |

Disconnect the vacuum hose from the electric EGR control valve assembly.

Start the engine.

Check if there is suction from the vacuum hose during idling.

- HINT:

- If idling continues for 15 minutes or more, the EGR valve target opening angle becomes 0% (EGR valve fully closed). As this makes diagnosis impossible, it becomes necessary to drive the vehicle or to restart the engine.

- OK:

- Suction exists.

| 8.REMOVE DEPOSIT (ELECTRIC EGR CONTROL VALVE ASSEMBLY) |

Remove the electric EGR control valve assembly (HILUX_TGN26 RM000002RK9023X.html).

Visually check the electric EGR control valve assembly for deposits. If there are deposits, clean the electric EGR control valve assembly.

- HINT:

- If the EGR valve is stuck closed, the intake air amount increases and engine vibration may worsen.

- If the EGR valve does not operate due to clogging or disconnection of the vacuum hose, repair the hose.

- If the EGR valve does not close properly or is stuck open, EGR becomes excessive and combustion becomes unstable. Also, there may be a lack of power.

Reinstall the electric EGR control valve assembly (HILUX_TGN26 RM000002RK6023X.html).

| 9.REPAIR OR REPLACE VACUUM HOSE |

Repair or replace of the EGR valve system vacuum hose.

Replace the EGR cooler.

| 11.READ VALUE USING INTELLIGENT TESTER (INJECTION VOLUME) |

Connect the intelligent tester to the DLC3.

Start the engine and warm it up until the engine coolant temperature reaches 70°C (158°F) or higher.

Allow the engine to idle for 1 minute or more.

- HINT:

- The A/C switch and all accessory switches should be off with a fully warm engine.

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / Injection Volume.

Read the values during engine idling.

ResultResult

| Proceed to

|

Injection Volume is less than 5 mm3/st

| A

|

Except above

| B

|

- HINT:

- If the injector assembly is malfunctioning, the compensatory injection volume remains at 5.0 mm3/st.

- If there is a disconnection, the feedback value will increase and +5.0 mm3/st will be indicated, because it will become impossible for the injector to inject.

| 12.REPLACE INJECTOR ASSEMBLIES OF ALL CYLINDERS |

Replace the injector assemblies (HILUX_TGN26 RM000002SY1021X.html).

| 13.BLEED AIR FROM FUEL SYSTEM |

Bleed the air from the fuel system (HILUX_TGN26 RM000002SY8025X_01_0002.html).

| 14.REGISTER INJECTOR COMPENSATION CODE AND PERFORM PILOT QUANTITY LEARNING |

Register the injector compensation code (HILUX_TGN26 RM0000012XK05BX_02_0003.html).

Perform the injector pilot quantity learning (HILUX_TGN26 RM0000012XK05BX_02_0009.html).

| 15.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the intelligent tester to the DLC3.

Clear the DTCs (HILUX_TGN26 RM000000PDK0XBX.html).

Turn the ignition switch off.

Start the engine and warm it up.

Confirm the value of Engine Speed from the Freeze Frame Data recorded previously, and then drive the vehicle according to the Engine Speed value.

- HINT:

- Take a snapshot of MAP and Target Boost Pressure in the Data List with the intelligent tester while driving the vehicle.

Read the DTCs.

ResultResult

| Proceed to

|

P1251 is not output and the amount by which MAP exceeds Target Boost Pressure is 20 kPa or less

| A

|

Except above

| B*

|

- HINT:

- *: Return to "Check Air Intake System" and inspect areas that have not been inspected yet.

| 16.CHECK HARNESS AND CONNECTOR (TURBO MOTOR DRIVER - TURBOCHARGER SUB-ASSEMBLY) |

Disconnect the DC motor connector.

Disconnect the nozzle vane position sensor connector.

Disconnect the turbo motor driver connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

C41-2 (M+) - C39-12 (M+)

| Always

| Below 1 Ω

|

C41-1 (M-) - C39-5 (M-)

| Always

| Below 1 Ω

|

C40-1 (VTA1) - C39-9 (VTA1)

| Always

| Below 1 Ω

|

C40-2 (VNE2) - C39-8 (VNE2)

| Always

| Below 1 Ω

|

C40-3 (VNVC) - C39-1 (VNVC)

| Always

| Below 1 Ω

|

C40-4 (VTA2) - C39-10 (VTA2)

| Always

| Below 1 Ω

|

C40-5 (E2S) - C39-11 (E2S)

| Always

| Below 1 Ω

|

C40-6 (VCS) - C39-6 (VCS)

| Always

| Below 1 Ω

|

C41-2 (M+) or C39-12 (M+) - Body ground

| Always

| 10 kΩ or higher

|

C41-1 (M-) or C39-5 (M-) - Body ground

| Always

| 10 kΩ or higher

|

C40-1 (VTA1) or C39-9 (VTA1) - Body ground

| Always

| 10 kΩ or higher

|

C40-2 (VNE2) or C39-8 (VNE2) - Body ground

| Always

| 10 kΩ or higher

|

C40-3 (VNVC) or C39-1 (VNVC) - Body ground

| Always

| 10 kΩ or higher

|

C40-4 (VTA2) or C39-10 (VTA2) - Body ground

| Always

| 10 kΩ or higher

|

C40-5 (E2S) or C39-11 (E2S) - Body ground

| Always

| 10 kΩ or higher

|

C40-6 (VCS) or C39-6 (VCS) - Body ground

| Always

| 10 kΩ or higher

|

Reconnect the DC motor connector.

Reconnect the nozzle vane position sensor connector.

Reconnect the turbo motor driver connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|