Rear Crankshaft Oil Seal -- Installation |

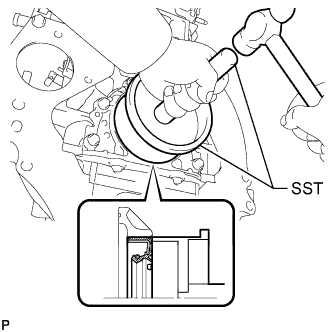

| 1. INSTALL REAR CRANKSHAFT OIL SEAL |

Apply a light coat of MP grease to the lip of a new oil seal.

- NOTICE:

- Do not allow foreign matter to contact the lip of the oil seal.

- Do not allow MP grease to contact the dust seal.

|

Using SST and a hammer, tap in the oil seal until its surface is flush with the oil seal retainer edge.

- SST

- 09223-15030

09950-70010(09951-07150)

- NOTICE:

- Wipe off any extra grease from the crankshaft.

- Do not tap in the oil seal at an angle.

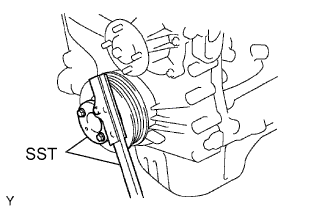

| 2. INSTALL FLYWHEEL SUB-ASSEMBLY |

Using SST, hold the crankshaft.

- SST

- 09213-54015(91651-60855)

09330-00021

|

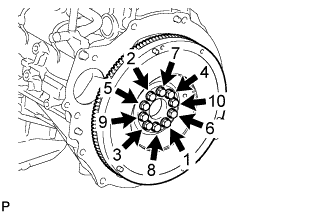

Clean the bolts and bolt holes.

Apply adhesive to 2 or 3 threads at the end of each of the 10 bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the flywheel with the 10 bolts and uniformly tighten the bolts in several steps in the sequence shown in the illustration.

- Torque:

- 27 N*m{270 kgf*cm, 20 ft.*lbf}

|

Mark the top of the bolts with paint.

Tighten the 10 bolts 90° in the same sequence.

Check that the paint marks are now at a 90° angle to the top.

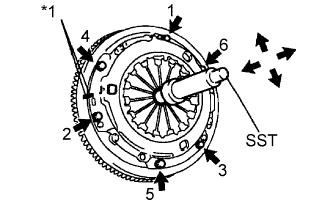

| 3. INSTALL CLUTCH DISC ASSEMBLY |

Insert SST into the clutch disc. Then insert SST (together with the clutch disc) into the flywheel.

- SST

- 09301-00110

- NOTICE:

- Be sure to install the clutch disc so that it is facing in the correct direction.

|

| 4. INSTALL CLUTCH COVER ASSEMBLY |

Align the matchmarks on the clutch cover and flywheel.

Text in Illustration *1 Matchmark

|

Tighten the 6 bolts as described below.

Determine the first bolt to be tightened by choosing the bolt closest to the knock pin.

Uniformly tighten the 6 bolts in diametrically opposite pairs relative to the position of the first bolt. Use the illustration as a reference.

Lightly move SST up and down, and right and left.

- SST

- 09301-00110

Check that the disc is in the center, and then tighten the bolts.

- Torque:

- 19 N*m{195 kgf*cm, 14 ft.*lbf}

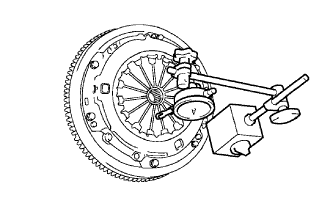

| 5. INSPECT AND ADJUST CLUTCH COVER ASSEMBLY |

Using a dial indicator with a roller instrument, measure the diaphragm spring tip alignment.

- Maximum misalignment:

- 0.5 mm (0.020 in.)

If the misalignment is more than the maximum, use SST to adjust the diaphragm spring tip alignment.

- SST

- 09333-00013

|

| 6. INSTALL MANUAL TRANSMISSION UNIT ASSEMBLY |