Starter (For 1.6 Kw Type) -- Reassembly |

- HINT:

- Use high-temperature grease to lubricate the bearings and sliding parts when assembling the starter.

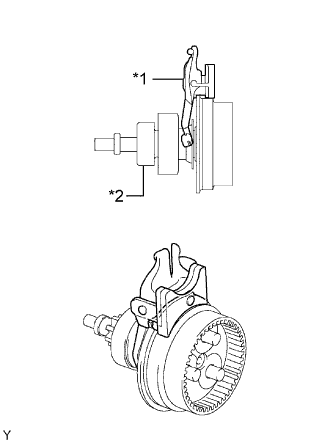

| 1. INSTALL STARTER CENTER BEARING CLUTCH SUB-ASSEMBLY |

Apply high-temperature grease to the starter drive lever set pin.

Text in Illustration

High-temperature Grease

|

Install the drive lever set pin to the starter center bearing clutch sub-assembly.

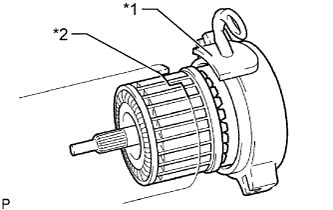

Text in Illustration *1 Drive Lever Set Pin *2 Starter Center Bearing Clutch

|

Install the starter center bearing clutch and drive lever set pin together to the starter drive housing.

| 2. INSTALL PLANETARY GEAR |

Apply high-temperature grease to the planetary gears and pin parts of the planetary shaft.

Text in Illustration

High-temperature Grease

|

Install the 3 planetary gears onto the pins of the planetary shaft.

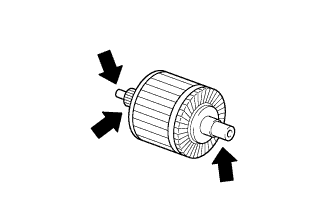

| 3. INSTALL STARTER ARMATURE ASSEMBLY |

- NOTICE:

- Do not drop the starter armature assembly.

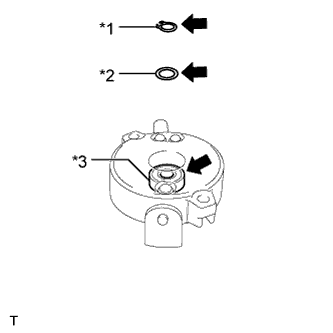

Apply high-temperature grease to the plate washer, a new snap ring and the bearing.

Text in Illustration *1 Snap Ring *2 Plate Washer *3 Bearing

High-temperature Grease

|

Mount the starter commutator end frame in a vise between aluminum plates.

- NOTICE:

- Do not damage the starter commutator end frame.

Apply high-temperature grease to the starter armature assembly.

Text in Illustration

High-temperature Grease

|

Install the starter armature assembly to the starter commutator end frame assembly.

Install the plate washer to the starter armature shaft.

Using snap ring pliers, install the snap ring.

- NOTICE:

- Be sure to install the snap ring in the armature shaft groove securely.

- Be sure to properly install the snap ring because it easily expands.

Check the snap ring length.

Using a vernier caliper, measure the snap ring length.

- Maximum length:

- 5.0 mm (0.197 in.)

If the length is more than the maximum, replace the snap ring.Text in Illustration *1 Length

|

| 4. INSTALL STARTER COMMUTATOR END FRAME COVER |

Install the commutator end frame cover into the starter commutator end frame.

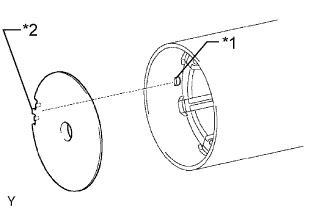

| 5. INSTALL STARTER ARMATURE PLATE |

Align the keyway of the starter armature plate with the key inside the starter yoke, and install the starter armature plate.

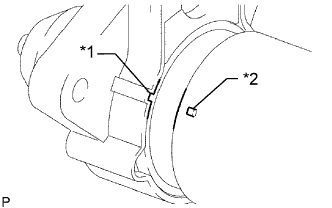

Text in Illustration *1 key *2 Keyway

|

| 6. INSTALL STARTER COMMUTATOR END FRAME ASSEMBLY |

Align the rubber part on the starter commutator end frame with the groove of the starter yoke.

Text in Illustration *1 Rubber Part *2 Groove

|

Install the starter commutator end frame to the starter yoke.

- NOTICE:

- The magnet of the starter yoke may attract the starter armature when the starter commutator end frame is installed, causing the magnet to break.

| 7. INSTALL STARTER YOKE ASSEMBLY |

Align the claw of the starter yoke with the groove inside the starter drive housing.

Text in Illustration *1 Groove *2 Claw

|

Install the starter yoke with the 2 through bolts.

- Torque:

- 6.0 N*m{61 kgf*cm, 53 in.*lbf}

| 8. INSTALL REPAIR SERVICE STARTER KIT |

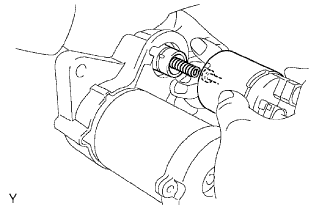

Apply high-temperature grease to the plunger and hook.

Text in Illustration

High-temperature Grease

|

Hang the plunger hook of the repair service starter kit on the drive lever set pin.

Install the plunger and return spring.

|

Install the repair service starter kit with the 2 screws.

- Torque:

- 7.5 N*m{77 kgf*cm, 66 in.*lbf}

Connect the lead wire to the terminal with the nut.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}