TEMPORARILY INSTALL ELECTRIC EGR CONTROL VALVE ASSEMBLY WITH NO. 2 EGR VALVE AND EGR COOLER

TIGHTEN ELECTRIC EGR CONTROL VALVE ASSEMBLY WITH NO. 2 EGR VALVE AND EGR COOLER

Camshaft (W/ Dpf) -- Installation |

- NOTICE:

- When replacing the injectors (including shuffling the injectors between the cylinders), common rail or cylinder head, it is necessary to replace the injection pipes with new ones.

- When replacing the fuel supply pump, common rail, cylinder block, cylinder head, cylinder head gasket or timing gear case, it is necessary to replace the fuel inlet pipe with a new one.

- After removing the injection pipes, clean them with a brush and compressed air.

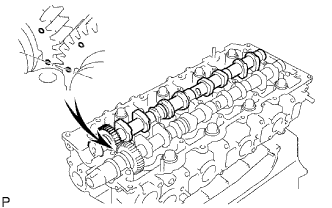

| 1. INSTALL CAMSHAFT |

Using the crankshaft pulley bolt, set the No. 1 cylinder to 90° BTDC/compression.

Text in Illustration *1 Key - HINT:

- Set the No. 1 cylinder to 90° BTDC/compression to prevent the top of the piston from hitting against the valve head.

|

Install the camshafts.

Apply engine oil to the thrust portion of the camshaft.

Place the camshaft on the cylinder head with the key groove facing upward.

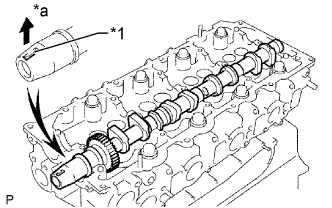

Text in Illustration *1 Key Groove *a Upward Align the timing marks (1-dot marks) of the camshaft drive and driven main gears and set the No. 2 camshaft in place.

|

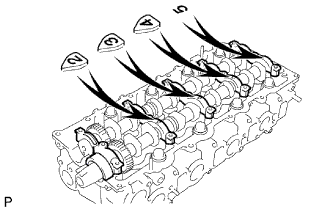

Remove any old seal packing (FIPG material) from the camshaft bearing cap.

Apply seal packing to the specified areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 4 mm (0.157 in.)

Text in Illustration *1 Seal Packing *2 Oil Passage - NOTICE:

- Do not allow seal packing to contact the oil passage of the bearing cap.

- After applying seal packing, install the camshaft bearing caps within 3 minutes and tighten the bolts within 15 minutes.

- Do not start the engine for at least 2 hours after installation.

|

Install the 5 bearing caps to their proper locations.

|

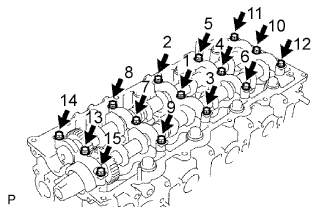

Apply a light coat of engine oil to the threads and under the heads of the bearing cap bolts.

|

Install and uniformly tighten the 15 bearing cap bolts in several passes in the sequence shown in the illustration.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

Install a new camshaft oil seal.

Apply MP grease to the lip of a new oil seal.

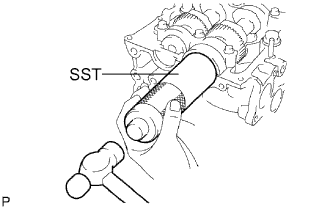

Using SST and a hammer, tap in the oil seal until its surface is flush with the surfaces of the camshaft bearing cap and cylinder head.

- SST

- 09608-06041

|

| 2. INSTALL NO. 2 TIMING BELT COVER |

Apply seal packing (FIPG) to the specified areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Text in Illustration *1 Seal Packing - NOTICE:

- After applying seal packing, install the No. 2 timing belt cover within 3 minutes and tighten the bolts and nut within 15 minutes.

|

Clean the bolts and their holes.

Apply adhesive to 2 or 3 threads at the end of each of the 4 bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the No. 2 timing belt cover with the 4 bolts and nut.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 3. INSTALL CAMSHAFT TIMING PULLEY |

Install the camshaft timing pulley.

Install the bolt of the camshaft timing pulley while holding the camshaft with a wrench.

- Torque:

- 98 N*m{1000 kgf*cm, 72 ft.*lbf}

| 4. INSTALL NO. 1 TIMING BELT IDLER SUB-ASSEMBLY |

Using a 10 mm hexagon wrench, install a new washer and the No. 1 timing belt idler with the bolt.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

Check that the idler pulley moves smoothly.

If the idler pulley does not move smoothly, check the installation condition of the idler and washer.

| 5. INSTALL TIMING BELT |

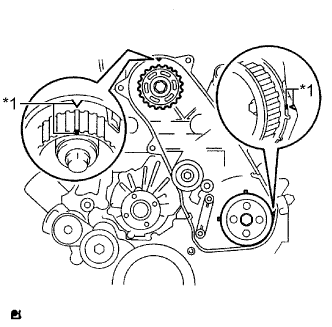

Check that the timing marks are aligned as shown in the illustration.

Text in Illustration *1 Timing Mark - NOTICE:

- Make sure that the engine is cold.

- When turning the crankshaft, the valve heads will hit against the piston. Do not turn the crankshaft more than necessary.

- HINT:

- If reusing the timing belt, align the points marked during removal, and install the belt with the arrow pointing in the direction of crankshaft revolution.

|

Install the timing belt to the pump drive shaft pulley, camshaft timing pulley and No. 1 timing belt idler in sequence.

Place the tensioner upright. Then set a press on the top of the tensioner.

- NOTICE:

- Do not scratch or deform the rod end.

- Press in the tensioner rod.

- Protect the tip of the push rod with a cloth in order to prevent damage.

|

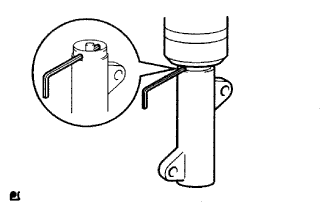

Using the press, slowly push in the push rod using 981 to 9800 N (100 to 999 kgf, 220 to 2203 lbf) of force.

- NOTICE:

- Do not apply a load of over 9800 N (999 kgf, 2203 lbf) to the push rod.

Align the holes of the push rod and housing. Then pass a 1.5 mm hexagon wrench through the holes to fix the push rod in place.

Temporarily install the timing belt tensioner with the 2 bolts while pushing the idler pulley toward the timing belt.

Tighten the 2 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

- NOTICE:

- Uniformly tighten the 2 bolts.

Remove the 1.5 mm hexagon wrench from the tensioner.

|

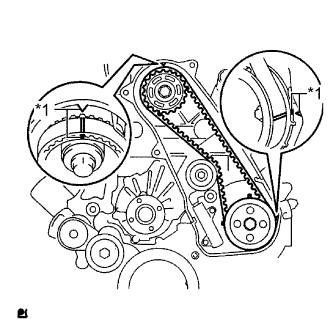

Turn the crankshaft clockwise 720° and check that the timing marks are aligned as shown in the illustration.

Text in Illustration *1 Timing Mark

|

| 6. INSPECT AND ADJUST VALVE CLEARANCE |

| 7. INSTALL NO. 1 TIMING BELT COVER |

Install the timing belt cover and 6 washers with the 6 bolts.

- Torque:

- 6.0 N*m{61 kgf*cm, 53 in.*lbf}

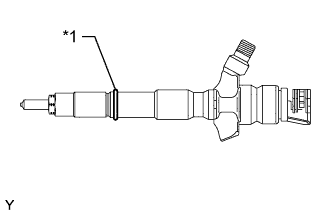

| 8. INSTALL INJECTOR ASSEMBLY |

- NOTICE:

- Be sure to install each injector, No. 1 nozzle holder clamp, washer and bolt to its original position.

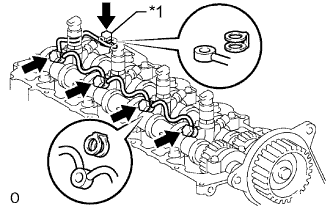

Install 4 new injection nozzle seats to the cylinder head.

|

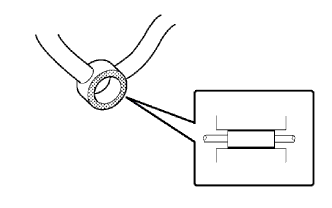

Apply a small amount of clean engine oil to 4 new O-rings.

Install one of the O-rings to each injector as shown in the illustration.

Text in Illustration *1 New O-Ring

|

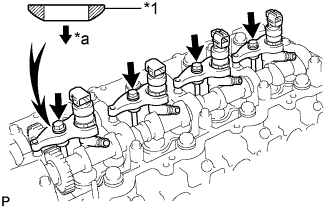

Insert the 4 injectors into the cylinder head.

- NOTICE:

- Insert the injector until it touches the injection nozzle seat surface.

- After installing the injector to the cylinder head, the O-ring may prevent the injector from being fully seated. If so, pull out the injector and reinstall it.

- Always reinstall an injector to the same place it was removed from.

For an injector that has been replaced with a new injector, register the injector compensation code (HILUX_TGN26 RM0000012XK059X_02_0003.html).

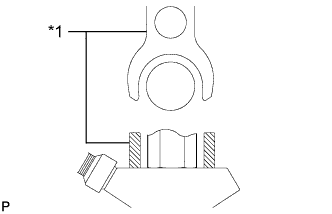

Temporarily install 4 new washers and the 4 No. 1 nozzle holder clamps with the 4 bolts.

Text in Illustration *1 New Washer *a Downward - NOTICE:

- The fork portion of the No. 1 nozzle holder clamp must be set on the injector.

- Before tightening the bolts, check that the No. 1 nozzle holder clamps are set properly.

- When installing the clamp bolts, first tighten them by hand until they cannot be turned further. Then, tighten the bolts to the specified torque in a following step.

- When tightening the bolts, be careful so as not to tilt the bolt or clamp.

- Do not reuse the washer.

Text in Illustration *1 No. 1 Nozzle Holder Clamp - HINT:

- Apply a small amount of engine oil to the threads and under the heads of the clamp bolts.

|

Temporarily install the 4 injection pipes with the union nuts.

- HINT:

- To position the injectors, loosely tighten the union nuts.

Check the nozzle leakage pipe. Check that there are no scratches or dents on the 5 union seal surfaces.

If scratches or dents are present, replace the nozzle leakage pipe.

|

Set the nozzle leakage pipe and 5 new gaskets in place.

Text in Illustration *1 Union Bolt

|

Apply a small amount of oil to the 4 injector hollow screws and union bolt.

Temporarily install the nozzle leakage pipe with the 4 injector hollow screws and union bolt.

Tighten the 4 nozzle holder clamp bolts.

- Torque:

- 22 N*m{220 kgf*cm, 16 ft.*lbf}

Remove the 4 injection pipes.

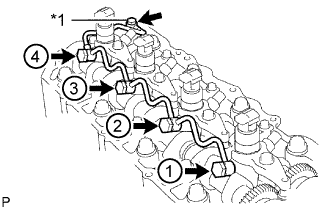

Tighten the 4 injector hollow screws in order from 1 to 4.

- Torque:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

Text in Illustration *1 Union Bolt - NOTICE:

- If an injector hollow screw is accidentally tightened beyond the torque specification, it must be replaced.

|

Tighten the union bolt.

- Torque:

- 13 N*m{127 kgf*cm, 9 ft.*lbf}

- NOTICE:

- If the union bolt is accidentally tightened beyond the torque specification, it must be replaced.

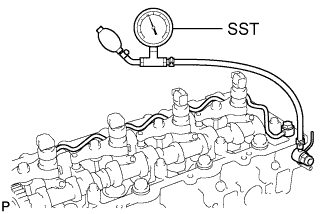

| 9. INSPECT FOR FUEL LEAK |

Check that there are no leaks from the nozzle leakage pipe connection.

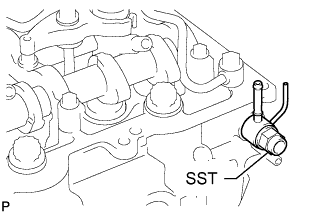

Install a new gasket and the No. 2 nozzle leakage pipe to the cylinder head with SST (check valve).

- Part No.:

- 23762-27010 (No. 2 nozzle leakage pipe)

- SST

- 09280-00010

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Apply a small amount of soapy water (or other fluid for detecting fuel leakage) on the nozzle leakage pipe connection.

Install SST (turbocharger pressure gauge) to the fuel return side of the nozzle leakage pipe, maintain 100 kPa (1.0 kgf/cm2, 15 psi) of pressure for 60 seconds and check that no bubbles form.

- SST

- 09992-00242

After checking for fuel leaks, wipe off the soapy water from the nozzle leakage pipe connection.

Remove SST, the No. 2 nozzle leakage pipe and gasket.

- NOTICE:

- Never reinstall the disassembled union bolt to the engine.

|

| 10. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY |

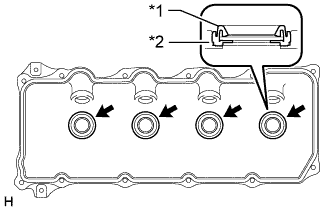

Install 4 new No. 3 cylinder head cover gaskets to the cylinder head cover in the directions shown in the illustration.

Text in Illustration *1 No. 3 Cylinder Head Cover Gasket *2 Cylinder Head Cover - NOTICE:

- Do not install the No. 3 cylinder head cover gaskets at an angle.

- Check that there is no foreign matter at the installation location of the No. 3 cylinder head cover gaskets.

|

Remove any old seal packing (FIPG material) from the cylinder head.

Apply seal packing to the areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Text in Illustration

Seal Packing - NOTICE:

- Remove any oil from the contact surface.

- Install the cylinder head cover within 3 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing the cylinder head cover.

|

Install a new cylinder head cover gasket to the cylinder head cover.

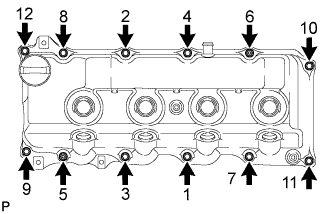

Temporarily install the cylinder head cover with the 10 bolts and 2 nuts in the order shown in the illustration. Then, tighten the 10 bolts and 2 nuts in the order shown in the illustration in 2 progressive steps.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

Connect the ventilation hose.

Install 4 new nozzle holder seals.

| 11. INSTALL NO. 2 CYLINDER HEAD COVER SUB-ASSEMBLY |

Install the No. 2 cylinder head cover with the 3 bolts.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 12. INSTALL NO. 2 NOZZLE LEAKAGE PIPE ASSEMBLY |

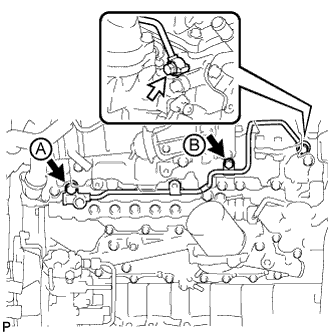

Temporarily install the No. 2 nozzle leakage pipe with the 2 bolts.

Text in Illustration

Union Bolt

|

Temporarily install a new gasket and the union bolt.

Tighten the 2 bolts and union bolt.

- Torque:

- for bolt A:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- for bolt B:

- 13 N*m{130 kgf*cm, 9 ft.*lbf}

- for union bolt:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 13. INSTALL NO. 3 NOZZLE LEAKAGE PIPE |

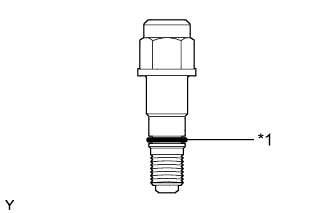

Apply a light coat of fuel to the O-ring of the fuel check valve.

Text in Illustration *1 O-Ring

|

Temporarily install the No. 3 nozzle leakage pipe with the 2 bolts.

Text in Illustration

Fuel Check Valve

|

Temporarily install a new gasket and the fuel check valve.

Tighten the 2 bolts and fuel check valve.

- Torque:

- for bolt:

- 13 N*m{130 kgf*cm, 9 ft.*lbf}

- for fuel check valve:

- 32 N*m{321 kgf*cm, 23 ft.*lbf}

Connect the 3 fuel hoses.

| 14. INSTALL NO. 2 FUEL PIPE |

Apply a light coat of fuel to the O-ring of the fuel check valve.

Text in Illustration *1 O-Ring

|

Temporarily install the No. 2 fuel pipe with the 3 bolts.

Text in Illustration *1 Gasket *2 No. 1 Fuel Pipe

Bolt

Supply Pump Hollow Screw

Fuel Check Valve

Union Bolt

|

Install a new gasket to the No. 1 fuel pipe and temporarily install the union bolt.

Temporarily install a new gasket and the fuel check valve.

- NOTICE:

- When temporarily installing the fuel check valve, position the gasket as shown in the illustration.

Temporarily install a new gasket and the supply pump hollow screw.

Using a 6 mm hexagon wrench, tighten the supply pump hollow screw.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Tighten the 3 bolts, fuel check valve and union bolt.

- Torque:

- for bolt:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

- for fuel check valve:

- 32 N*m{321 kgf*cm, 23 ft.*lbf}

- for union bolt:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- NOTICE:

- When tightening the fuel check valve, replace the gasket if it becomes deformed.

| 15. INSTALL WIRING HARNESS CLAMP BRACKET |

Install the wiring harness clamp bracket with the bolt.

- Torque:

- 13 N*m{128 kgf*cm, 9 ft.*lbf}

Attach the wire harness clamp.

| 16. INSTALL NO. 4 INJECTION PIPE SUB-ASSEMBLY |

- NOTICE:

- When replacing an injector, it is necessary to replace the 4 injection pipes with new ones.

- Keep the joints of the injection pipe clean.

Temporarily install the No. 4 injection pipe with the union nuts.

Install the 2 No. 2 injection pipe clamps with the bolt and nut.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Using a 17 mm union nut wrench, tighten the injection pipe union nut on the common rail side.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1006X.html).

Using a 17 mm union nut wrench, tighten the injection pipe union nuts on the injector side.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1006X.html).

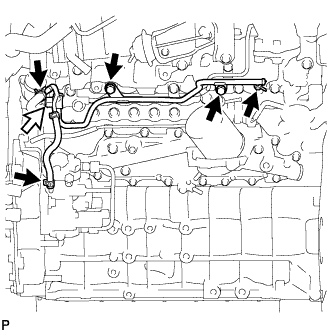

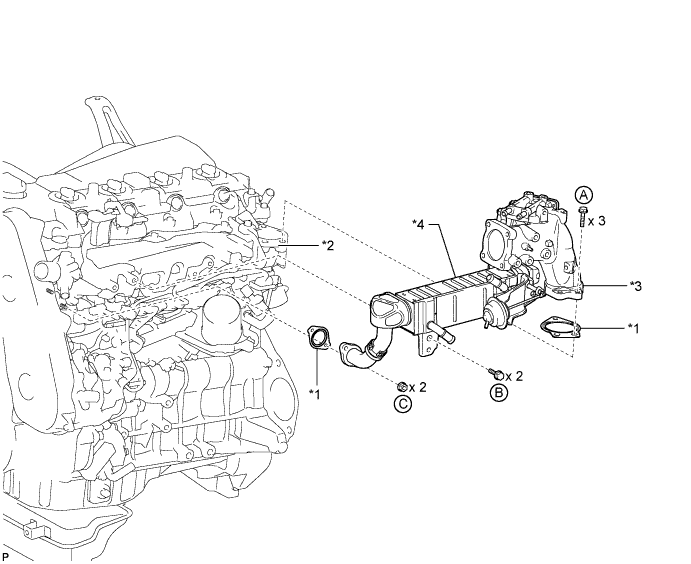

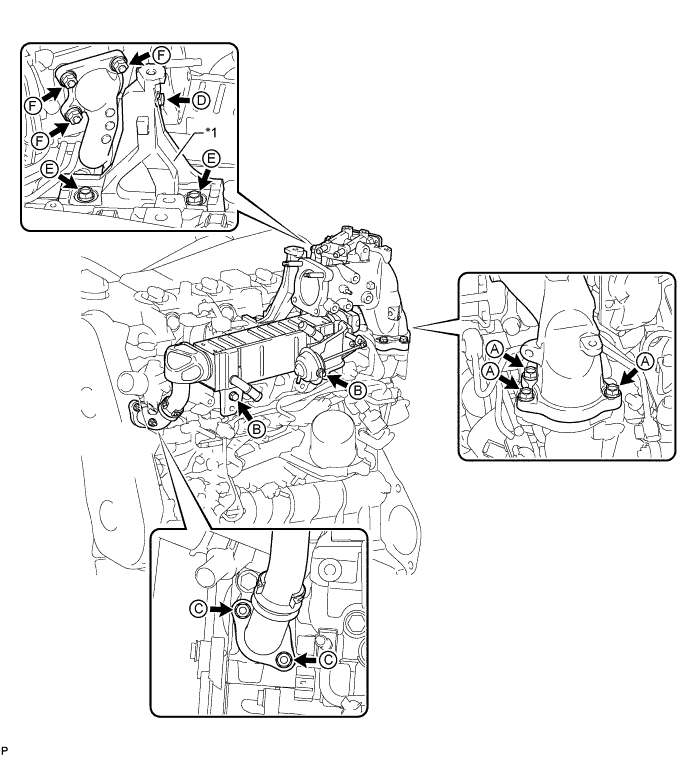

| 17. TEMPORARILY INSTALL ELECTRIC EGR CONTROL VALVE ASSEMBLY WITH NO. 2 EGR VALVE AND EGR COOLER |

Install a new gasket to the intake manifold.

Install a new gasket to the stud bolts of the cylinder head.

Set the electric EGR control valve with No. 2 EGR valve and EGR cooler on the intake manifold and cylinder head.

Temporarily install the intake air connector to the intake manifold with the 3 bolts labeled A in the illustration.

Temporarily install the EGR cooler to the intake manifold with the 2 bolts labeled B in the illustration.

Temporarily install the EGR cooler to the cylinder head with the 2 nuts labeled C in the illustration.

Text in Illustration *1 New Gasket *2 Intake Manifold *3 Intake Air Connector *4 EGR Cooler

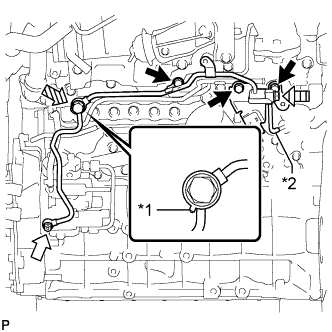

| 18. TIGHTEN ELECTRIC EGR CONTROL VALVE ASSEMBLY WITH NO. 2 EGR VALVE AND EGR COOLER |

Tighten the 3 bolts labeled A in the illustration.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Tighten the 2 bolts labeled B in the illustration.

- Torque:

- 22 N*m{224 kgf*cm, 16 ft.*lbf}

Tighten the 2 nuts labeled C in the illustration.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Temporarily install the EGR valve bracket with the 3 bolts.

Tighten the bolt labeled D in the illustration.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Tighten the 2 bolts labeled E in the illustration.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Tighten the 3 nuts labeled F in the illustration.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Text in Illustration *1 EGR Valve Bracket - -

Connect the fuel pressure sensor connector to the common rail.

| 19. CONNECT NO. 3 WATER BY-PASS PIPE |

Connect the No. 3 water by-pass pipe with the 2 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

| 20. CONNECT ENGINE WIRE |

Connect the engine wire with the bolt.

- Torque:

- 13 N*m{128 kgf*cm, 9 ft.*lbf}

Attach the 2 wire harness clamps.

| 21. INSTALL THROTTLE BODY BRACKET |

Install the throttle body bracket with the 3 bolts.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

| 22. INSTALL WIRING HARNESS CLAMP BRACKET |

Install the wiring harness clamp bracket with the bolt.

- Torque:

- 13 N*m{128 kgf*cm, 9 ft.*lbf}

| 23. INSTALL GAS FILTER BRACKET WITH GAS FILTER |

Install the gas filter bracket with gas filter with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Connect the vacuum hose.

| 24. INSTALL MANIFOLD ABSOLUTE PRESSURE SENSOR |

Install the manifold absolute pressure sensor with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Connect the vacuum hose and manifold absolute pressure sensor connector.

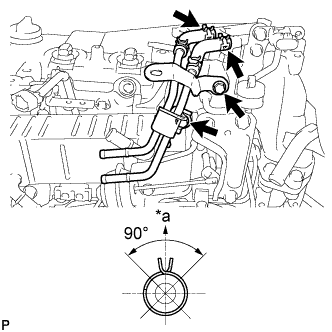

| 25. INSTALL NO. 5 WATER BY-PASS PIPE |

Install the No. 5 water by-pass pipe with the 2 bolts.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Text in Illustration *a Upper Side

|

Connect the 2 water hoses to the electric EGR control valve.

- HINT:

- Push the water hoses on until they contact the body of the electric EGR control valve.

- The direction of the hose clamps is indicated in the illustration.

Attach the 2 wire harness clamps.

| 26. INSTALL NO. 1, NO. 2 AND NO. 3 INJECTION PIPE SUB-ASSEMBLY |

- NOTICE:

- When replacing an injector, it is necessary to replace the 4 injection pipes with new ones.

- Keep the joints of the injection pipe clean.

Temporarily install the No. 1, No. 2 and No. 3 injection pipes with the union nuts.

Install the 2 No. 3 injection pipe clamps with the 4 nuts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Using a 17 mm union nut wrench, tighten the injection pipe union nuts on the common rail side.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1006X.html).

Using a 17 mm union nut wrench, tighten the injection pipe union nuts on the injector side.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1006X.html).

| 27. INSTALL FUEL INLET PIPE SUB-ASSEMBLY |

Temporarily install the fuel inlet pipe with the union nuts.

- NOTICE:

- When replacing the fuel supply pump, it is necessary to replace the fuel inlet pipe with a new one.

- Keep the fuel inlet pipe free of foreign matter.

Install the No. 2 injection pipe clamp with the bolt.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Text in Illustration *1 Fuel Inlet Pipe *2 Paint Mark *3 No. 2 Fuel Pipe - HINT:

- When installing the No. 2 injection pipe clamp, align it with the paint mark of the fuel inlet pipe shown in the illustration.

|

Using a 17 mm union nut wrench, tighten the fuel inlet pipe union nut on the common rail side.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1006X.html).

Using a 17 mm union nut wrench, tighten the fuel inlet pipe union nut on the fuel supply pump side.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1006X.html).

| 28. INSTALL NO. 3 CYLINDER HEAD COVER SUB-ASSEMBLY |

Install the No. 3 cylinder head cover with the 3 bolts.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 29. INSTALL MANIFOLD STAY WITH VACUUM SWITCHING VALVE |

Install the manifold stay with vacuum switching valve with the 2 bolts.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

Connect the 2 vacuum transmitting hoses.

Connect the vacuum switching valve connector.

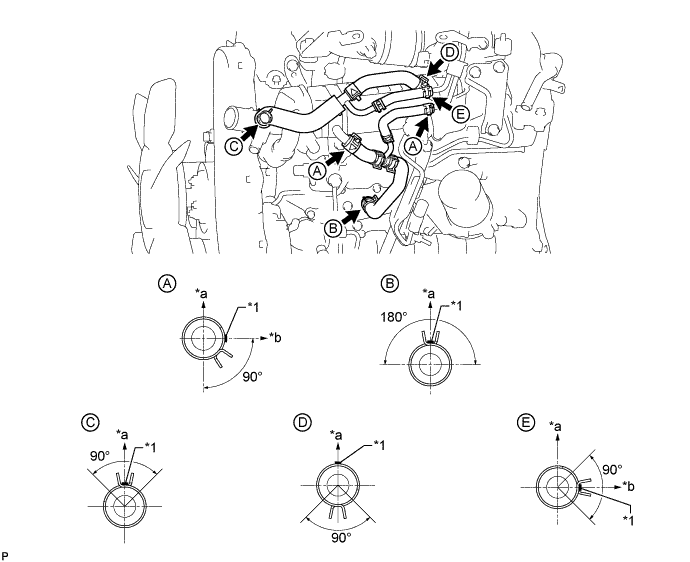

| 30. CONNECT WATER BY-PASS HOSE |

Connect the 6 water by-pass hoses.

- HINT:

- When connecting the hoses, make sure the paint marks and clamps are as shown in the illustration.

- The direction of each hose clamp is indicated in the illustration.

Text in Illustration *1 Paint Mark - - *a Upper Side *b LH Side

| 31. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE |

Install a new O-ring to the engine oil level dipstick guide.

Apply a small amount of clean engine oil to the O-ring.

Install the engine oil level dipstick guide with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Attach the wire harness clamp.

Install the engine oil level dipstick.

| 32. INSTALL FRONT FENDER SEAL |

Install the front fender seal with the 5 clips.

| 33. INSTALL FRONT FENDER APRON SEAL UPPER |

Install the front fender apron seal upper with the 5 clips.

| 34. INSTALL FRONT WHEEL LH |

| 35. INSTALL DIESEL THROTTLE BODY ASSEMBLY |

Install a new gasket and the diesel throttle body with the 2 bolts and 2 nuts.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Connect the 2 connectors.

| 36. INSTALL INTERCOOLER ASSEMBLY |

Install a new gasket and the intake air connector with the 4 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Install a new No. 2 air hose.

Install the intercooler with the 4 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

Tighten the 2 hose clamps of the No. 2 air hose.

- Torque:

- 6.5 N*m{66 kgf*cm, 58 in.*lbf}

Tighten the 2 hose clamps of the No. 1 air hose.

- Torque:

- 6.5 N*m{66 kgf*cm, 58 in.*lbf}

| 37. INSTALL INTAKE AIR TEMPERATURE SENSOR |

Using a 22 mm deep socket wrench, install a new gasket and the intake air temperature sensor.

- Torque:

- 29 N*m{300 kgf*cm, 22 ft.*lbf}

Connect the intake air temperature sensor connector.

| 38. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY |

Install the No. 1 engine cover with the 3 bolts and 2 cap nuts.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

| 39. INSTALL FAN SHROUD |

Install the fan pulley to the water pump.

Install the fan shroud together with the fluid coupling with fan between the radiator and engine component.

- NOTICE:

- Be careful not to damage the radiator core.

Install the fluid coupling with fan to the fan pulley with the 4 nuts.

Tighten the nuts as much as possible by hand.

Attach the claws of the fan shroud to the radiator.

|

Install the fan shroud with the 2 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Install the fan and generator V belt (HILUX_TGN26 RM000001474016X_01_0001.html).

Tighten the 4 nuts of the fluid coupling with fan.

- Torque:

- 23 N*m{235 kgf*cm, 17 ft.*lbf}

Install the radiator reservoir with the 2 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Connect the No. 1 and No. 2 water by-pass hoses to the radiator.

Install the oil reservoir with the 3 bolts.

- Torque:

- 4.5 N*m{46 kgf*cm, 40 in.*lbf}

| 40. INSTALL RADIATOR HOSE INLET |

| 41. ADD ENGINE OIL |

Add new engine oil.

- Standard Oil Grade:

Item Oil Grade Oil Viscosity (SAE) w/o DPF G-DLD1, API CF-4, CF or ACEA B1 - 5W-30

- 10W-30

- 15W-40

- 20W-50w/ DPF ACEA C2 - 0W-30

- 5W-30

- Standard Capacity:

Item Specified Condition Drain and refill without oil filter change 6.6 liters (7.0 US qts, 5.8 Imp. qts) Drain and refill with oil filter change 6.9 liters (7.3 US qts, 6.1 Imp. qts) Dry fill 7.4 liters (7.8 US qts, 6.5 Imp. qts)

Install the oil filler cap.

| 42. BLEED AIR FROM FUEL SYSTEM |

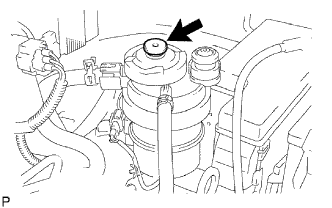

Using the hand pump mounted on the fuel filter cap, bleed the air from the fuel system. Continue pumping until the pump resistance increases.

- NOTICE:

- Hand pump pumping speed: Max. 2 strokes/ sec.

- The hand pump must be pushed with a full stroke during pumping.

- When the fuel pressure at the supply pump inlet port reaches a saturated pressure, the hand pump resistance increases.

- If pumping is interrupted during the air bleeding process, fuel in the fuel line may return to the fuel tank. Continue pumping until the hand pump resistance increases.

- If the hand pump resistance does not increase despite consecutively pumping 200 times or more, there may be a fuel leak between the fuel tank and fuel filter, the hand pump may be malfunctioning, or the vehicle may have run out of fuel.

- If air bleeding using the hand pump is incomplete, the common rail pressure does not rise to the pressure range necessary for normal use, and the engine cannot be started.

|

Check if the engine starts.

- NOTICE:

- Even if air bleeding using the hand pump has been completed, the starter may need to be cranked for 10 seconds or more to start the engine.

- Do not crank the engine continuously for more than 20 seconds. The battery may be discharged.

- Use a fully-charged battery.

When the engine can be started, proceed to the next step.

If the engine cannot be started, bleed the air again using the hand pump until the hand pump resistance increases (refer to the procedures above). Then start the engine.

Turn the ignition switch off.

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON and turn the intelligent tester on.

Clear the DTCs (HILUX_TGN26 RM000000PDK0X3X.html).

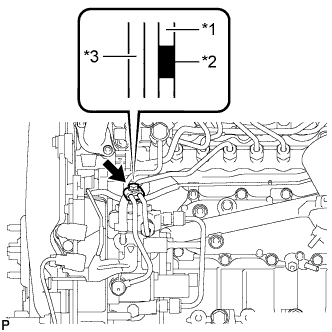

Start the engine.*1

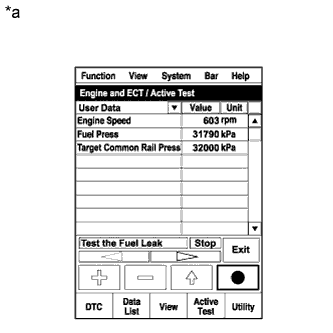

Enter the following menus: Powertrain / Engine / Active Test / Test the Fuel Leak.*2

Text in Illustration *a Reference

(Active Test Operation)

|

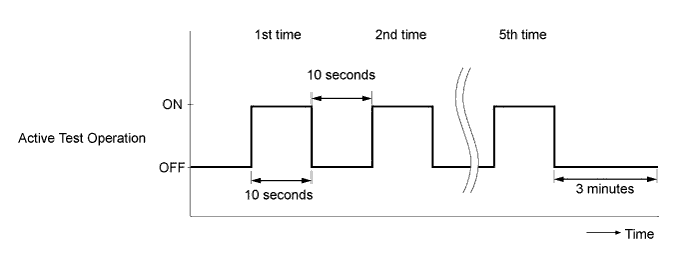

Perform the following test 5 times with on/off intervals of 10 seconds: Active Test / Test the Fuel Leak.*3

Allow the engine to idle for 3 minutes or more after performing the Active Test for the fifth time.

- HINT:

- When the Active Test "Test the Fuel Leak" is used to change the pump control mode, the actual fuel pressure inside the common rail drops below the target fuel pressure when the Active Test is off, but this is normal and does not indicate a pump malfunction.

Enter the following menus: Powertrain / Engine / DTC.

Read Current DTCs.

Clear the DTCs (HILUX_TGN26 RM000000PDK0X3X.html).

- HINT:

- It is necessary to clear the DTCs, as DTC P1604 or P1605 may be stored when air is bled from the fuel system after replacing or repairing fuel system parts.

Repeat steps *1 to *3.

Enter the following menus: Powertrain / Engine / DTC.

Read Current DTCs.

- OK:

- No DTCs are output.

| 43. ADD ENGINE COOLANT |

Tighten the radiator drain cock plug by hand.

Tighten the cylinder block drain cock plug.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Fill the radiator with TOYOTA Super Long Life Coolant (SLLC) to the B line of the radiator reservoir.

- Standard capacity:

- 9.8 liters (10.4 US qts, 8.6 Imp. qts)

- NOTICE:

- Never use water as a substitute for engine coolant.

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

- Please contact your TOYOTA dealer for further details.

Press the inlet and outlet radiator hoses several times by hand, and then check the level of the coolant.

If the coolant level drops below the B line, add TOYOTA SLLC to the B line.

Install the radiator reservoir cap.

Using a wrench, install the vent plug.

- Torque:

- 2.0 N*m{20 kgf*cm, 17 in.*lbf}

Bleed air from the cooling system.

Warm up the engine until the thermostat opens. While the thermostat is open, circulate the coolant for several minutes.

Maintain the engine speed at 2500 to 3000 rpm.

Press the inlet and outlet radiator hoses several times by hand to bleed air.

- CAUTION:

- When pressing the radiator hoses:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan.

Stop the engine and wait until the coolant cools down to ambient temperature.

- CAUTION:

- Do not remove the radiator reservoir cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

After the coolant cools down, check that the coolant level is at the F line.

If the coolant level is below the F line, add TOYOTA SLLC to the F line.

| 44. INSPECT FOR COOLANT LEAK |

- CAUTION:

- Do not remove the radiator reservoir cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

- NOTICE:

- Before each inspection, turn the A/C switch off.

Fill the radiator with coolant and attach a radiator cap tester.

Warm up the engine.

Using the radiator cap tester, increase the pressure inside the radiator to 118 kPa (1.2 kgf/cm2, 17 psi), and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator and water pump for leaks. If no external leaks are found, check the heater core, cylinder block and head.

| 45. INSPECT FOR OIL LEAK |

Start the engine. Make sure that there are no oil leaks from the areas that were worked on.

| 46. INSPECT FOR FUEL LEAK |

Perform the Active Test.

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Turn the intelligent tester on.

Enter the following menus: Powertrain / Engine / Active Test.

Perform the Active Test.

Intelligent Tester Display Test Part Control Range Diagnostic Note Test the Fuel Leak Pressurize common rail interior and check for fuel leaks Stop/Start - The fuel pressure inside the common rail increases to the specified value and the engine speed increases to 2000 rpm when the Active Test is performed.

- The above conditions are maintained while the Active Test is being performed.

- The fuel pressure inside the common rail increases to the specified value and the engine speed increases to 2000 rpm when the Active Test is performed.

| 47. INSTALL NO. 1 ENGINE UNDER COVER |

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

| 48. INSPECT ENGINE OIL LEVEL |

Warm up the engine, stop the engine and wait 5 minutes. The engine oil level should be between the dipstick low level mark and full level mark.

If low, check for leakage and add oil up to the full level mark.- NOTICE:

- Do not fill engine oil above the full level mark.