Automatic Transmission Unit Reassembly

Drivetrain. Hilux. Tgn26, 36 Kun25, 26, 35, 36 Ggn25

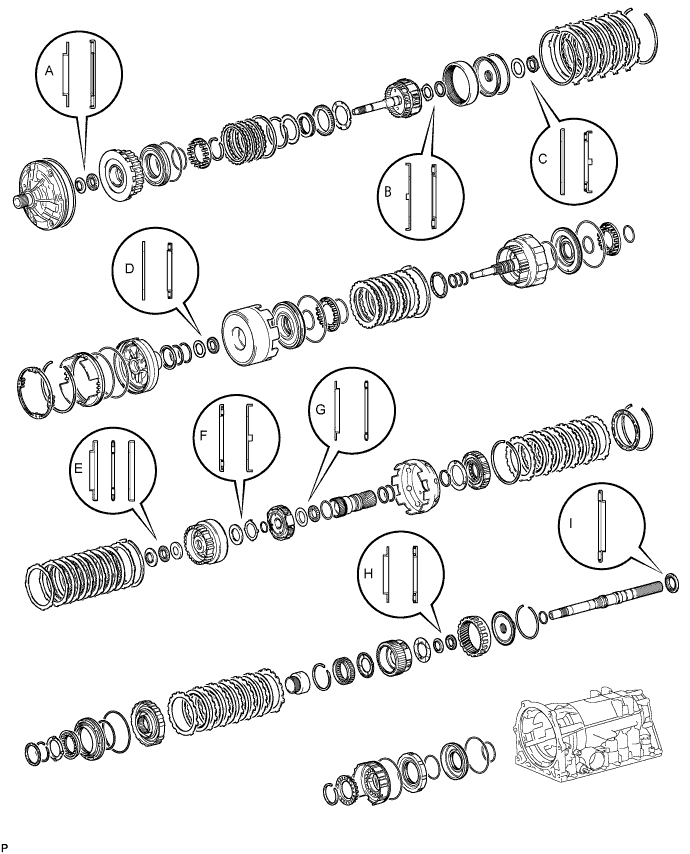

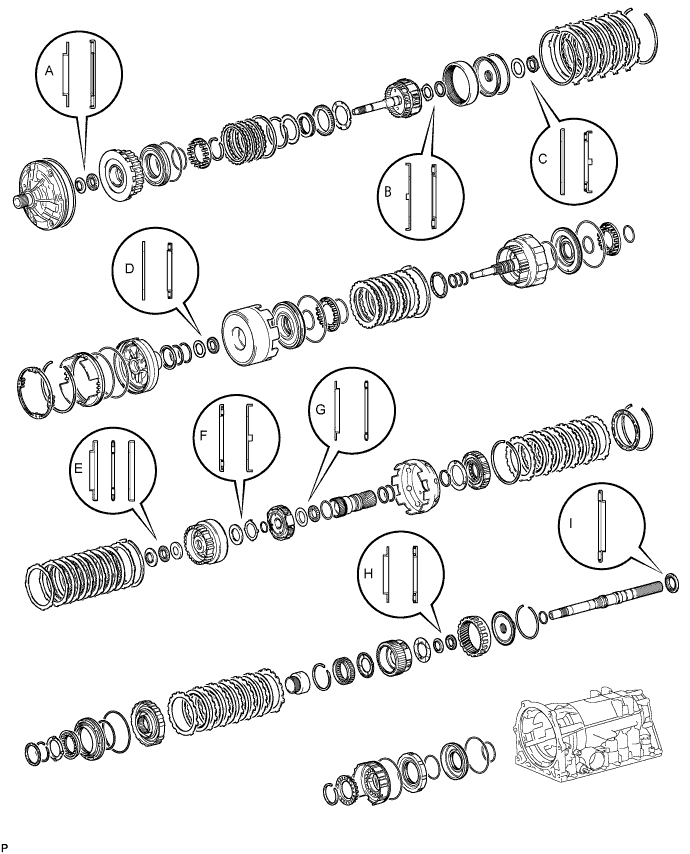

BEARING POSITION

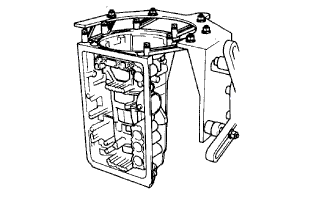

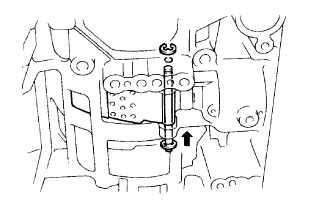

FIX TRANSMISSION CASE

INSTALL NO. 1 FIRST AND REVERSE BRAKE PISTON

INSTALL NO. 2 FIRST AND REVERSE BRAKE PISTON

INSTALL FIRST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY

INSPECT PISTON OPERATION OF FIRST AND REVERSE BRAKE

INSTALL LEAF SPRING

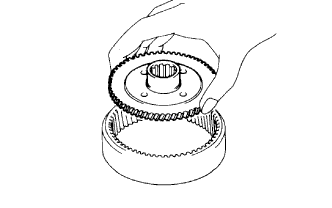

INSTALL NO. 2 1-WAY CLUTCH

INSPECT NO. 2 1-WAY CLUTCH

INSTALL REAR PLANETARY GEAR ASSEMBLY

INSTALL PLANETARY OUTPUT SHAFT OIL SEAL RING

INSTALL OUTPUT SHAFT

INSTALL SECOND BRAKE PISTON

INSTALL SECOND BRAKE PISTON RETURN SPRING SUB-ASSEMBLY

INSPECT SECOND BRAKE PISTON

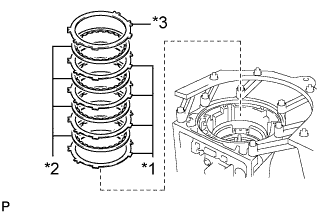

INSTALL NO. 4 PLANETARY CARRIER THRUST WASHER

INSTALL FIRST AND REVERSE BRAKE DISC SET

INSTALL OUTPUT SHAFT WITH REAR PLANETARY GEAR, NO. 2 1-WAY CLUTCH, FIRST AND REVERSE BRAKE DISC SET AND SECOND BRAKE DRUM

SELECT FIRST AND REVERSE BRAKE FLANGE

INSTALL SECOND BRAKE PISTON SLEEVE

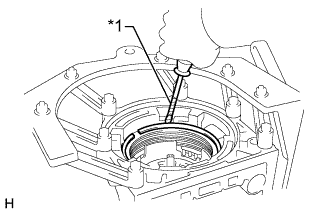

INSTALL BRAKE DRUM GASKET

INSTALL NO. 1 1-WAY CLUTCH ASSEMBLY

INSTALL SECOND BRAKE DISC SET

INSPECT SECOND BRAKE

INSTALL SUN GEAR INPUT DRUM SHAFT SNAP RING

INSTALL SUN GEAR INPUT DRUM

INSTALL SUN GEAR SHAFT OIL SEAL RING

INSTALL NO. 1 1-WAY CLUTCH THRUST WASHER

INSTALL PLANETARY SUN GEAR SUB-ASSEMBLY WITH SUN GEAR INPUT DRUM

INSTALL FRONT PLANETARY GEAR ASSEMBLY

INSTALL SECOND COAST BRAKE BAND ASSEMBLY

INSTALL INPUT SHAFT OIL SEAL RING

INSTALL FORWARD CLUTCH PISTON SUB-ASSEMBLY

INSTALL FORWARD CLUTCH RETURN SPRING SUB-ASSEMBLY

INSTALL FORWARD CLUTCH DISC SET

SELECT FORWARD CLUTCH FLANGE

INSTALL DIRECT CLUTCH PISTON SUB-ASSEMBLY

INSTALL DIRECT CLUTCH RETURN SPRING SUB-ASSEMBLY

INSTALL DIRECT CLUTCH DISC SET

SELECT DIRECT CLUTCH FLANGE

INSTALL DIRECT CLUTCH ASSEMBLY

INSTALL FRONT PLANETARY RING GEAR SUB-ASSEMBLY

INSTALL DIRECT CLUTCH ASSEMBLY WITH FORWARD CLUTCH ASSEMBLY

INSTALL SECOND COAST BRAKE PISTON ROD

INSTALL SECOND COAST BRAKE PISTON OIL SEAL RING

INSTALL SECOND COAST BRAKE PISTON ASSEMBLY

INSPECT PISTON STROKE OF SECOND COAST BRAKE

INSTALL OVERDRIVE BRAKE PISTON

INSTALL OVERDRIVE BRAKE RETURN SPRING SUB-ASSEMBLY

INSPECT PISTON OPERATION OF OVERDRIVE BRAKE

INSTALL OVERDRIVE CLUTCH DRUM OIL SEAL RING

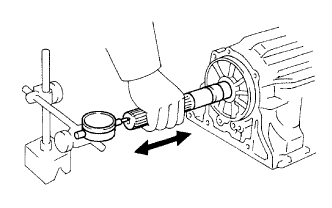

INSTALL OVERDRIVE BRAKE ASSEMBLY

INSPECT OUTPUT SHAFT END PLAY

INSTALL OVERDRIVE BRAKE DISC SET

SELECT OVERDRIVE BRAKE FLANGE

INSTALL OVERDRIVE PLANETARY RING GEAR FLANGE

INSTALL OVERDRIVE PLANETARY RING GEAR

INSTALL NO. 3 OVERDRIVE PLANETARY GEAR THRUST WASHER

INSTALL OVERDRIVE 1-WAY CLUTCH

INSTALL OVERDRIVE RETAINING PLATE

INSPECT OVERDRIVE 1-WAY CLUTCH

INSTALL OVERDRIVE DIRECT CLUTCH PISTON SUB-ASSEMBLY

INSTALL OVERDRIVE DIRECT CLUTCH RETURN SPRING SUB-ASSEMBLY

INSTALL OVERDRIVE DIRECT CLUTCH DISC SET

SELECT OVERDRIVE CLUTCH FLANGE

INSTALL OVERDRIVE DIRECT CLUTCH DRUM SUB-ASSEMBLY

INSTALL OVERDRIVE PLANETARY GEAR ASSEMBLY WITH DIRECT CLUTCH ASSEMBLY AND OVERDRIVE 1-WAY CLUTCH ASSEMBLY

INSTALL OIL PUMP ASSEMBLY

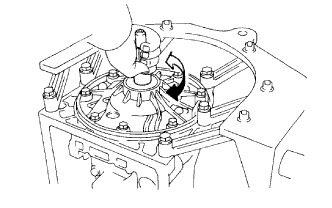

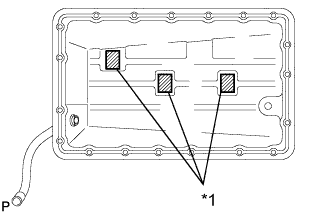

INSPECT INPUT SHAFT ROTATION

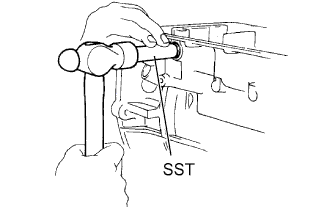

INSPECT INDIVIDUAL PISTON OPERATION

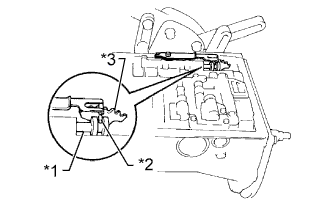

INSTALL MANUAL VALVE LEVER SHAFT OIL SEAL

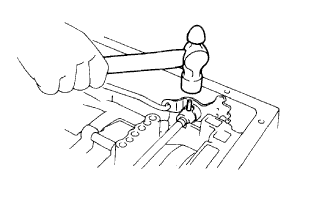

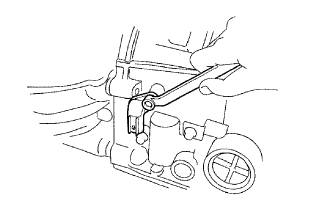

INSTALL MANUAL VALVE LEVER SHAFT

INSTALL PARKING LOCK PAWL

INSTALL PARKING LOCK ROD SUB-ASSEMBLY

INSTALL PARKING LOCK PAWL BRACKET

INSTALL C-0 ACCUMULATOR PISTON

INSTALL B-0 ACCUMULATOR PISTON

INSTALL C-2 ACCUMULATOR PISTON

INSTALL B-2 ACCUMULATOR PISTON

INSTALL CHECK BALL BODY

INSTALL TRANSMISSION VALVE BODY ASSEMBLY

INSTALL TRANSMISSION WIRE

INSTALL VALVE BODY OIL STRAINER ASSEMBLY

INSTALL OIL CLEANER MAGNET

INSTALL AUTOMATIC TRANSMISSION OIL PAN SUB-ASSEMBLY

INSTALL SENSOR ROTOR

INSTALL SPEEDOMETER DRIVE GEAR

INSTALL AUTOMATIC TRANSMISSION EXTENSION HOUSING OIL SEAL

INSTALL EXTENSION HOUSING DUST DEFLECTOR

INSTALL EXTENSION HOUSING BUSH APPLY TUBE GASKET

INSTALL EXTENSION HOUSING BUSH APPLY TUBE

INSTALL EXTENSION HOUSING SUB-ASSEMBLY

INSTALL AUTOMATIC TRANSMISSION HOUSING

INSTALL SPEED SENSOR SP2

INSTALL SPEEDOMETER SENSOR

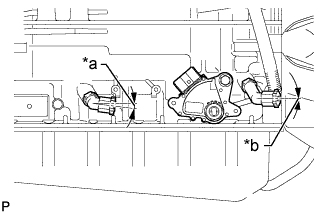

INSTALL SPEED SENSOR NC0

INSTALL OIL COOLER TUBE UNION

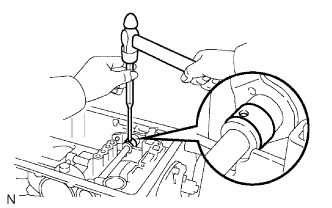

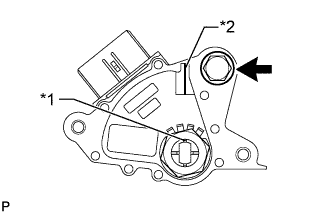

INSTALL ATF TEMPERATURE SENSOR

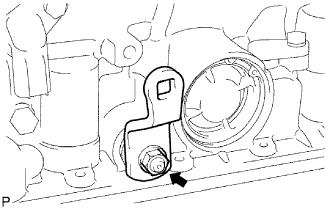

INSTALL PARK/NEUTRAL POSITION SWITCH ASSEMBLY

INSTALL TRANSMISSION CONTROL SHAFT LEVER LH

INSTALL BREATHER HOSE

INSTALL DRAIN PLUG

Automatic Transmission Unit -- Reassembly |

- Bearing Diameter:

Mark

| Front Race Diameter

Inside/Outside

| Thrust Bearing Diameter

Inside/Outside

| Rear Race Diameter

Inside/Outside

|

A

| 28.45 mm (1.12 in.)/47.1 to 47.35 mm (1.854 to 1.864 in.)

| 29.04 to 29.25 mm (1.144 to 1.151 in.)/50.04 to 50.34 mm (1.970 to 1.981 in.)

| -

|

B

| 33.0 to 33.25 mm (1.300 to 1.309 in.)/49.9 to 50.4 mm (1.97 to 1.98 in.)

| 31.45 to 31.70 mm (1.239 to 1.248 in.)/49.1 to 49.4 mm (1.934 to 1.944 in.)

| -

|

C

| 37.1 to 37.3 mm (1.461 to 1.468 in.)/58.70 to 58.95 mm (2.311 to 2.320 in.)

| 33.75 to 33.85 mm (1.329 to 1.332 in.)/49.8 to 50.3 mm (1.961 to 1.980 in.)

| -

|

D

| 36.5 to 37 mm (1.44 to 1.45 in.)/50.75 to 50.95 mm (1.999 to 2.005 in.)

| 33.55 to 33.80 mm (1.321 to 1.330 in.)/47.62 to 47.87 mm (1.875 to 1.884 in.)

| -

|

E

| 25.98 mm (1.02 in.)/48.87 mm (1.92 in.)

| 25.94 to 26.07 mm (1.022 to 1.026 in.)/46.62 to 46.87 mm (1.835 to 1.845 in.)

| 26.5 to 27.0 mm (1.043 to 1.062 in.)/47.02 mm (1.85 in.)

|

F

| -

| 35 to 35.3 mm (1.378 to 1.389 in.)/53.50 to 53.75 mm (2.107 to 2.116 in.)

| 34 to 34.5 mm (1.34 to 1.35 in.)/48.5 to 49 mm (1.91 to 1.92 in.)

|

G

| 33.55 to 33.80 mm (1.321 to 1.330 in.)/47.3 to 47.8 mm (1.87 to 1.88 in.)

| 35.45 to 35.61 mm (1.396 to 1.401 in.)/47.62 to 47.87 mm (1.875 to 1.884 in.)

| -

|

H

| 28.5 mm (1.12 in.)/44.2 mm (1.74 in.)

| 27.65 to 27.8 mm (1.089 to 1.094 in.)/44.2 mm (1.74 in.)

| -

|

I

| -

| 39.38 mm (1.55 in.)/57.94 to 58.24 mm (2.282 to 2.292 in.)

| -

|

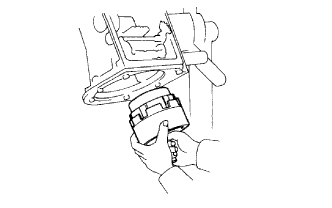

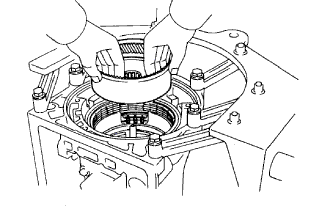

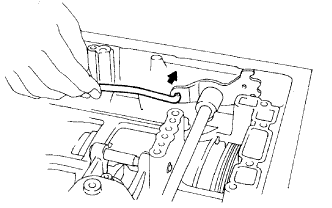

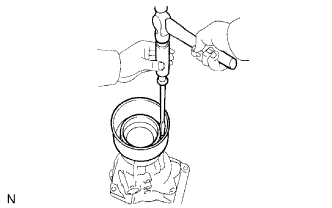

Install the transmission case to an overhaul attachment.

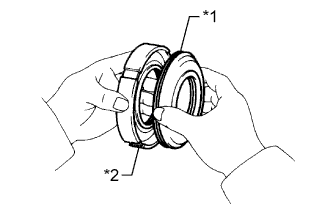

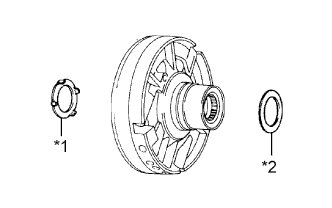

| 3. INSTALL NO. 1 FIRST AND REVERSE BRAKE PISTON |

Coat 2 new O-rings with ATF and install them to the No. 1 brake piston.

Coat a new O-ring with ATF and install it to the reaction sleeve.

Install the No. 1 brake piston to the reaction sleeve.

Text in Illustration*1

| No. 1 First and Reverse Brake Piston

|

*2

| Reaction Sleeve

|

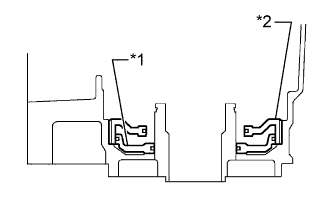

With the No. 1 brake piston on the bottom (the rear side), install the brake reaction sleeve and No. 1 brake piston to the transmission case.

Text in Illustration*1

| No. 1 First and Reverse Brake Piston

|

*2

| Reaction Sleeve

|

- NOTICE:

- Be careful not to damage the O-rings.

| 4. INSTALL NO. 2 FIRST AND REVERSE BRAKE PISTON |

Coat a new O-ring with ATF and install it to the brake piston.

With the spring seat of the piston facing upward (the front side), install the piston to the transmission case.

Text in Illustration*1

| No. 2 First and Reverse Brake Piston

|

- NOTICE:

- Be careful not to damage the O-ring.

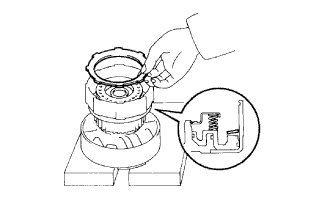

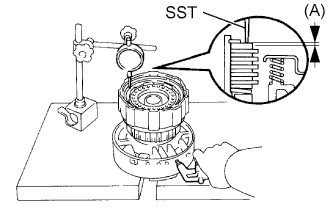

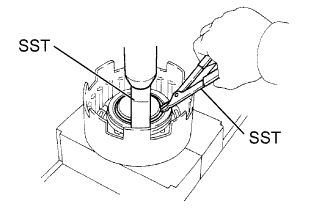

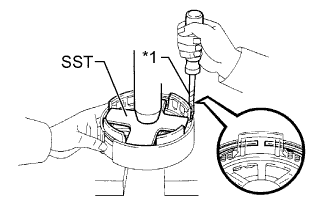

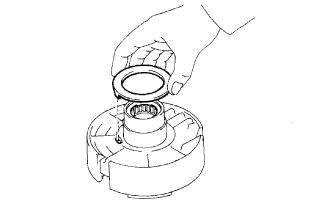

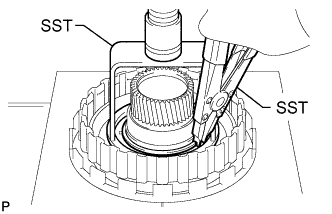

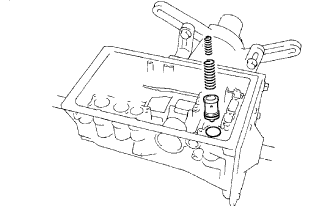

| 5. INSTALL FIRST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY |

Install the return spring to the brake piston.

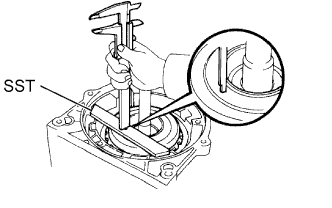

Place SST on the brake return spring and compress the brake return spring.

- SST

- 09350-30020(09350-07050)

Using SST, install the snap ring. Make sure the end gap of the snap ring is not aligned with a return spring claw.

- SST

- 09350-30020(09350-07070)

Text in Illustration*1

| Snap Ring

|

*2

| Return Spring Claw

|

| 6. INSPECT PISTON OPERATION OF FIRST AND REVERSE BRAKE |

Make sure the first and reverse brake pistons move smoothly when compressed air is applied into the transmission case.

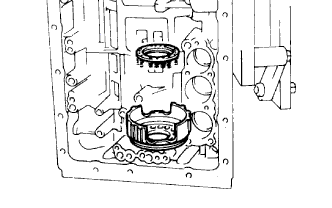

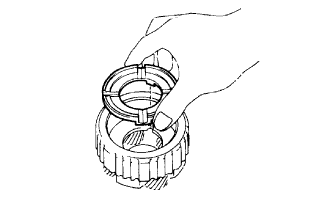

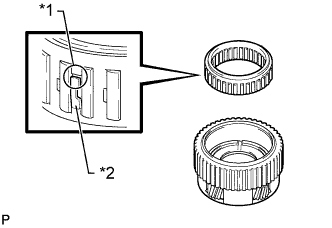

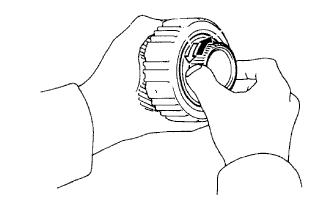

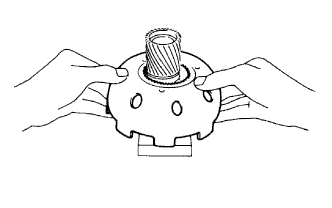

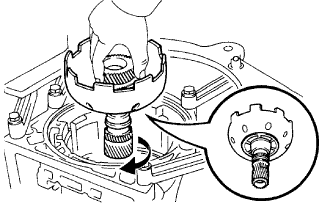

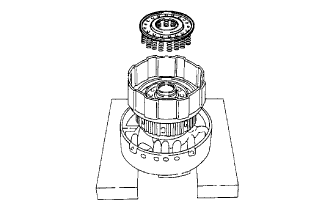

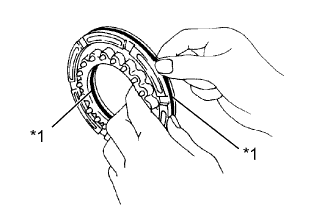

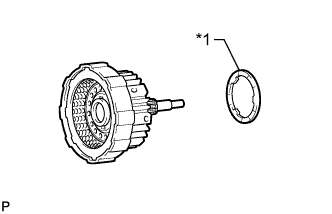

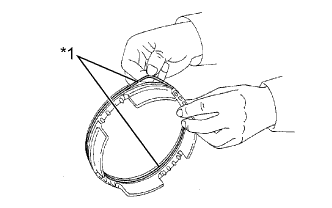

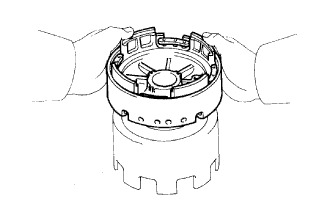

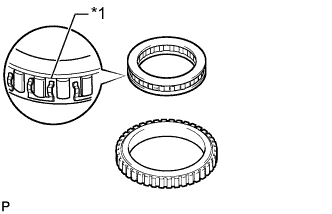

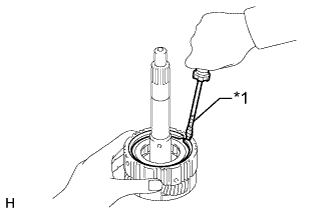

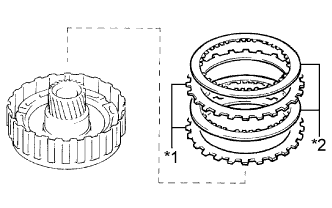

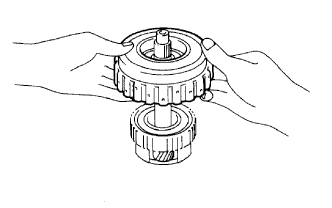

| 8. INSTALL NO. 2 1-WAY CLUTCH |

Coat the No. 2 planetary carrier thrust washer with petroleum jelly.

Install the No. 2 planetary carrier thrust washer to the rear planetary gear.

- HINT:

- Make sure that the tabs of the washer fit into the cutout portions of the rear planetary gear.

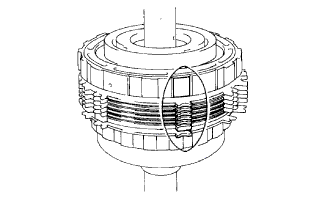

Install the 1-way clutch to the rear planetary gear.

- HINT:

- Make sure that the open ends of the guides of the 1-way clutch are facing upward.

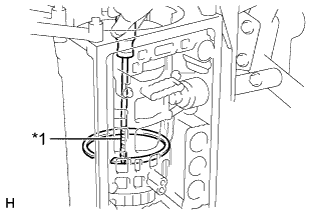

Text in Illustration*1

| Open End

|

*2

| Guide

|

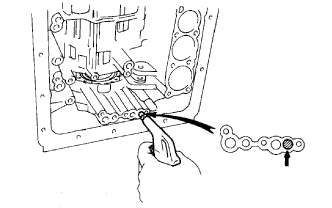

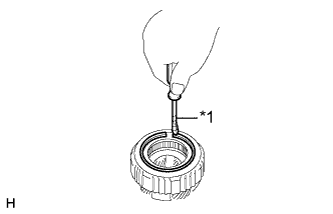

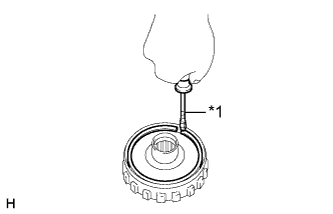

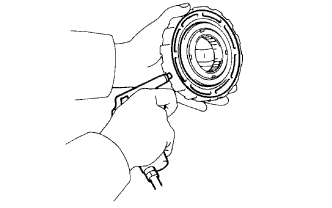

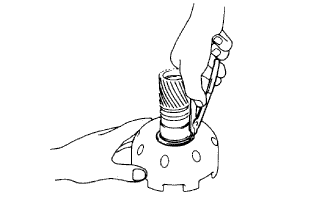

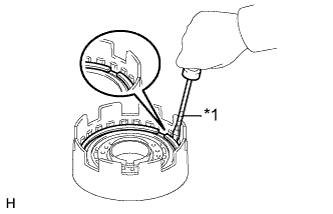

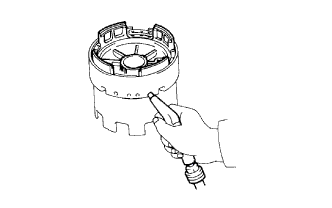

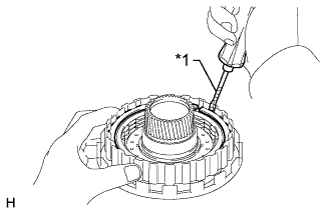

Using a screwdriver, install the snap ring.

Text in Illustration*1

| Protective tape

|

- NOTICE:

- Be careful not to damage the rear planetary gear.

- HINT:

- Tape the screwdriver tip before use.

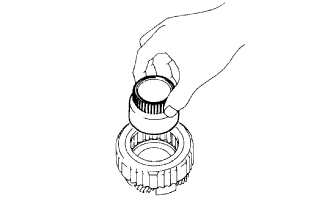

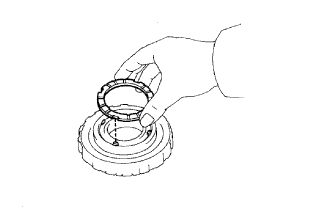

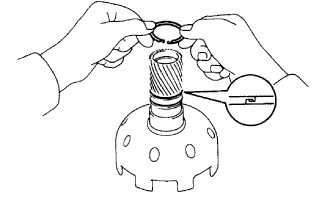

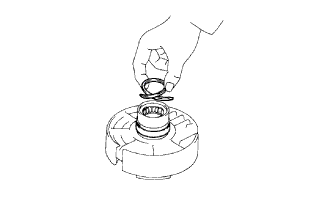

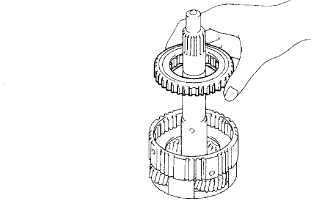

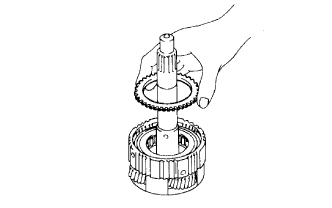

While turning the 1-way clutch inner race counterclockwise, install the 1-way clutch inner race to the planetary gear.

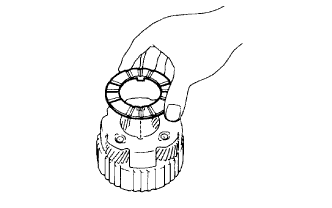

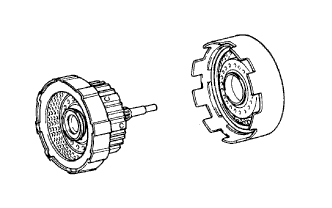

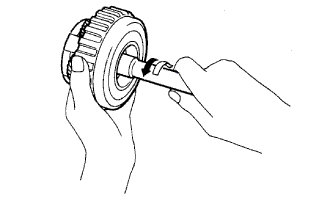

| 9. INSPECT NO. 2 1-WAY CLUTCH |

Hold the planetary gear and turn the 1-way clutch inner race. Check that the 1-way clutch inner race can be turned counterclockwise freely and locks when turned clockwise.

Text in Illustration

| Lock

|

| Free

|

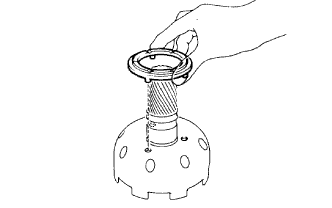

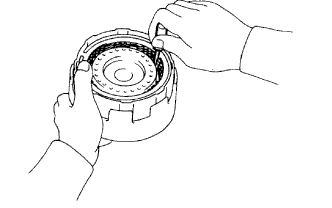

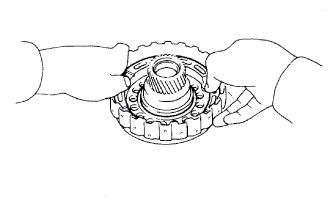

| 10. INSTALL REAR PLANETARY GEAR ASSEMBLY |

Install the ring gear flange to the rear planetary ring gear.

Using a screwdriver, install the snap ring.

Text in Illustration*1

| Protective tape

|

- NOTICE:

- Be careful not to damage the rear planetary ring gear.

- HINT:

- Tape the screwdriver tip before use.

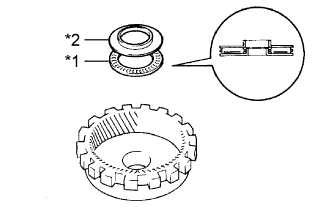

Coat the bearing and bearing race with petroleum jelly and install them to the rear planetary ring gear.

- Bearing and Bearing Race Diameter:

Item

| Inside

| Outside

|

Bearing H

| 27.65 to 27.8 mm (1.089 to 1.094 in.)

| 44.2 mm (1.74 in.)

|

Bearing Race H

| 28.5 mm (1.12 in.)

| 44.2 mm (1.74 in.)

|

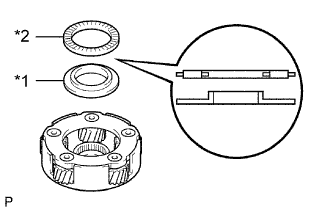

Text in Illustration*1

| Bearing H

|

*2

| Bearing Race H

|

Coat the No. 1 planetary carrier thrust washer with petroleum jelly.

Install the No. 1 planetary carrier thrust washer to the planetary gear.

- HINT:

- Make sure that the tabs of the washer fit into the cutout portions of the planetary gear.

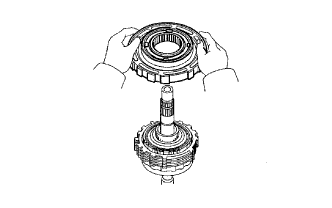

Install the rear planetary gear to the rear planetary ring gear.

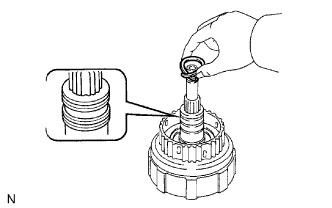

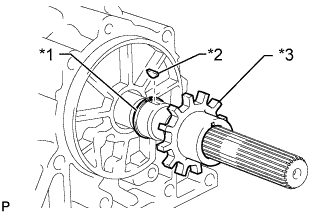

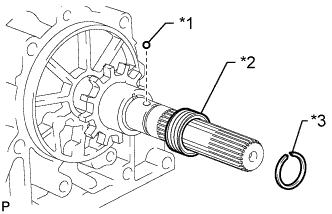

| 11. INSTALL PLANETARY OUTPUT SHAFT OIL SEAL RING |

Coat a new oil seal ring with ATF and install it to the output shaft.

- HINT:

- After installing the oil seal ring, check that it rotates smoothly.

- NOTICE:

- Do not expand the ring excessively.

Install the output shaft to the rear planetary gear flange.

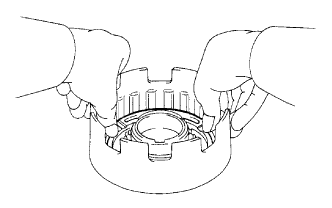

| 13. INSTALL SECOND BRAKE PISTON |

Coat 2 new O-rings with ATF and install them to the second brake piston.

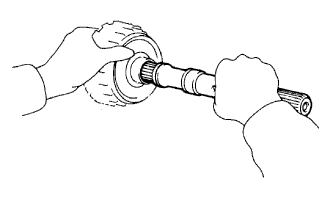

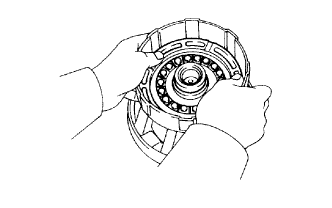

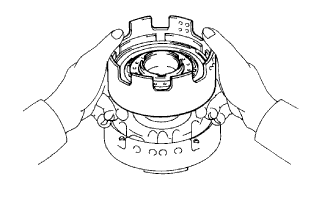

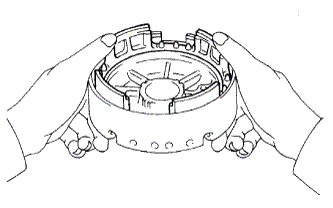

Being careful not to damage the O-rings, press the second brake piston toward the second brake drum with both hands.

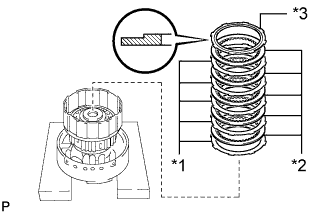

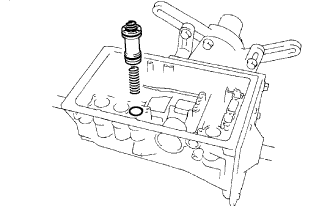

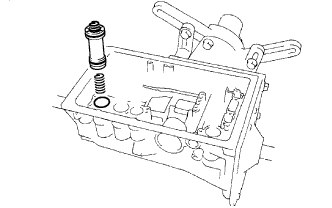

| 14. INSTALL SECOND BRAKE PISTON RETURN SPRING SUB-ASSEMBLY |

Install the piston return spring.

Install the second brake piston return spring seat.

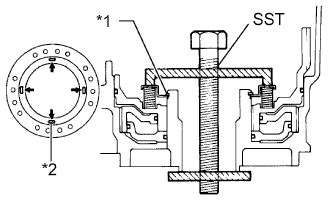

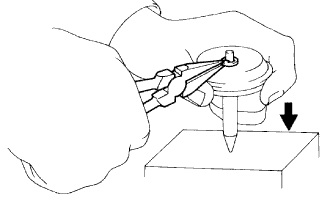

Place SST on the spring seat and compress the return spring with a press.

- SST

- 09350-30020(09350-07040)

- NOTICE:

- Do not deform the spring seat. Stop compressing the spring when the spring seat is lowered to a position 1 to 2 mm (0.0394 to 0.0787 in.) from the snap ring groove.

Using SST, install the snap ring.

- SST

- 09350-30020(09350-07070)

| 15. INSPECT SECOND BRAKE PISTON |

Check that the second brake piston moves smoothly when applying compressed air to and releasing low-pressure compressed air from the second brake drum.

| 16. INSTALL NO. 4 PLANETARY CARRIER THRUST WASHER |

Coat the thrust washer with petroleum jelly and install it.

- HINT:

- Make sure that the cutout portions of the thrust washer fit onto the teeth of the spring seat.

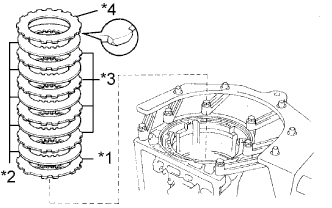

| 17. INSTALL FIRST AND REVERSE BRAKE DISC SET |

Install the flange with the rounded edge facing upward.

Install the 6 discs and 6 plates.

- Install in order:

- *1 - *2 - *3 - *2 - *3 - *2 - *3 - *2 - *3 - *2 - *3 - *2 - *3

Text in Illustration*1

| Flange

|

*2

| Disc

|

*3

| Plate

|

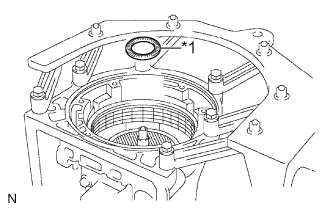

| 18. INSTALL OUTPUT SHAFT WITH REAR PLANETARY GEAR, NO. 2 1-WAY CLUTCH, FIRST AND REVERSE BRAKE DISC SET AND SECOND BRAKE DRUM |

Coat the bearing with petroleum jelly and install it to the case.

- Bearing Diameter:

Item

| Inside

| Outside

|

Bearing I

| 39.38 mm (1.55 in.)

| 57.94 to 58.24 mm (2.282 to 2.292 in.)

|

- NOTICE:

- Make sure the bearing is installed facing the proper direction.

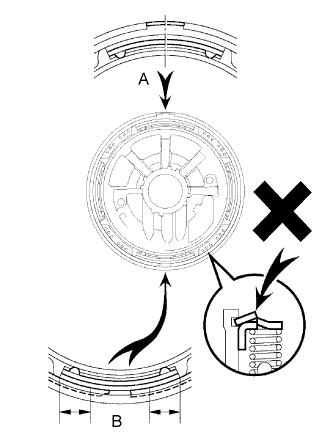

Align the teeth on the flange, discs and plates.

Install the second brake drum to the planetary gear with the snap ring facing upwards.

- NOTICE:

- Make sure the oil hole in the drum faces towards the lower side of the transmission case (the side where the valve body is installed).

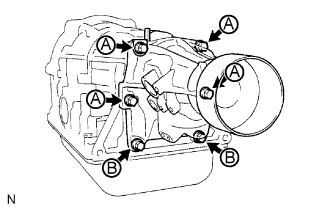

Align the teeth of the planetary gear assembly, indicated by A in the illustration, with the splines of the transmission case, indicated by B in the illustration.

Install the assembled planetary gear.

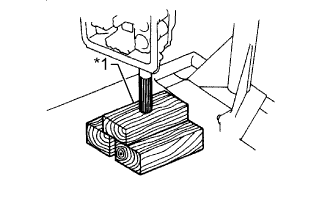

Place the output shaft on wooden blocks.

Text in Illustration*1

| Wooden Block

|

Using SST, install the snap ring.

- SST

- 09350-30020(09350-07060)

| 19. SELECT FIRST AND REVERSE BRAKE FLANGE |

Using a feeler gauge, measure the clearance between the plate and second brake drum.

- Standard clearance:

- 0.70 to 1.22 mm (0.0276 to 0.0480 in.)

If the clearance is not as specified, select a flange of an appropriate thickness from the table below so that the measured value is within the standard range.

- Flange Thickness:

Mark

| Thickness

|

55

| 3.94 to 4.06 mm (0.156 to 0.159 in.)

|

54

| 4.14 to 4.26 mm (0.163 to 0.167 in.)

|

53

| 4.34 to 4.46 mm (0.171 to 0.175 in.)

|

52

| 4.54 to 4.66 mm (0.179 to 0.183 in.)

|

51

| 4.74 to 4.86 mm (0.187 to 0.191 in.)

|

50

| 4.92 to 5.08 mm (0.194 to 0.199 in.)

|

66

| 5.10 to 5.30 mm (0.201 to 0.208 in.)

|

67

| 5.30 to 5.50 mm (0.209 to 0.216 in.)

|

| 20. INSTALL SECOND BRAKE PISTON SLEEVE |

| 21. INSTALL BRAKE DRUM GASKET |

Coat a new gasket with ATF and install it.

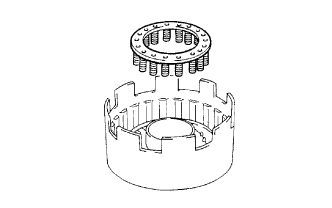

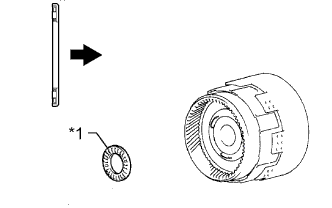

| 22. INSTALL NO. 1 1-WAY CLUTCH ASSEMBLY |

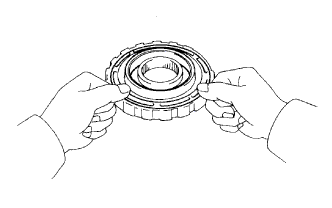

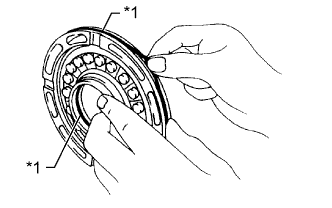

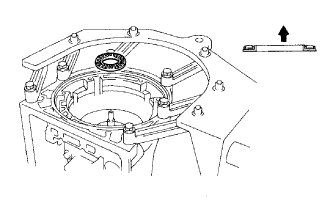

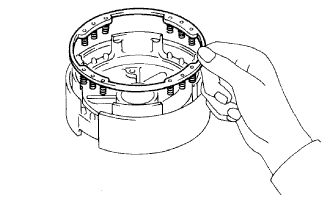

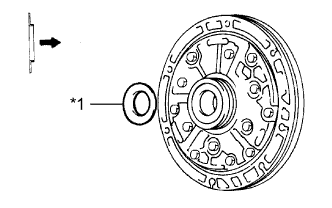

Install the 1-way clutch as shown in the illustration.

| 23. INSTALL SECOND BRAKE DISC SET |

Install the plate (A) with the rounded edge of the plate facing the discs.

- Plate Thickness:

Item

| Specified Condition

|

Plate (A)

| 1.8 mm (0.0709 in.)

|

Plate (B)

| 2.5 mm (0.0984 in.)

|

Text in Illustration*1

| Plate (A)

|

*2

| Disc

|

*3

| Plate (B)

|

*4

| Flange

|

Install the 5 discs, 5 plates and flange.

- Install in order:

- *1 - *2 - *3 - *2 - *3 - *2 - *3 - *2 - *3 - *2 - *4

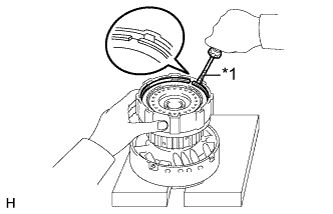

Using a screwdriver, install the snap ring.

Text in Illustration*1

| Protective Tape

|

- NOTICE:

- Be careful not to damage the transmission case.

- HINT:

- Tape the screwdriver tip before use.

Using a feeler gauge, measure the clearance between the snap ring and flange.

- Standard clearance:

- 0.62 to 1.98 mm (0.0245 to 0.0779 in.)

If the clearance is not as specified, inspect the discs.

| 25. INSTALL SUN GEAR INPUT DRUM SHAFT SNAP RING |

Using a screwdriver, install the snap ring to the planetary sun gear.

Text in Illustration*1

| Protective Tape

|

- NOTICE:

- Be careful not to damage the front planetary sun gear sub-assembly.

- HINT:

- Tape the screwdriver tip before use.

| 26. INSTALL SUN GEAR INPUT DRUM |

Place the planetary sun gear onto a wooden block or similar object.

Install the input drum to the planetary sun gear.

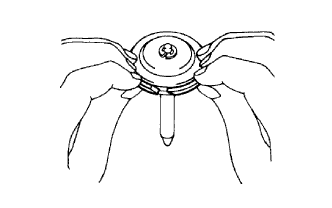

Using snap ring pliers, install the snap ring.

| 27. INSTALL SUN GEAR SHAFT OIL SEAL RING |

Coat 2 new oil seal rings with ATF.

Install the 2 oil seal rings to the planetary sun gear.

- NOTICE:

- Do not expand the rings excessively.

- HINT:

- After installing the oil seal rings, check that they rotate smoothly.

| 28. INSTALL NO. 1 1-WAY CLUTCH THRUST WASHER |

- HINT:

- Make sure that the tabs of the washer fit into the holes in the sun gear input drum.

| 29. INSTALL PLANETARY SUN GEAR SUB-ASSEMBLY WITH SUN GEAR INPUT DRUM |

While turning the sun gear clockwise, install it to the 1-way clutch.

- HINT:

- Confirm that the thrust washer is installed correctly.

| 30. INSTALL FRONT PLANETARY GEAR ASSEMBLY |

Coat the bearing and bearing race with petroleum jelly and install them to the planetary gear.

- Bearing and Bearing Race Diameter:

Item

| Inside

| Outside

|

Bearing Race G

| 33.55 to 33.80 mm (1.321 to 1.330 in.)

| 47.3 to 47.8 mm (1.87 to 1.88 in.)

|

Bearing G

| 35.45 to 35.61 mm (1.396 to 1.401 in.)

| 47.62 to 47.87 mm (1.875 to 1.884 in.)

|

Text in Illustration*1

| Bearing Race G

|

*2

| Bearing G

|

- NOTICE:

- Make sure the bearing and race are installed facing the proper directions.

Install the planetary gear to the sun gear input drum.

Using SST, install the snap ring.

- SST

- 09350-30020(09350-07070)

Remove the wooden blocks from under the output shaft.

Coat the bearing race with petroleum jelly and install it to the planetary gear.

- Bearing Race Diameter:

Item

| Inside

| Outside

|

Bearing Race F

| 34 to 34.5 mm (1.34 to 1.35 in.)

| 48.5 to 49 mm (1.91 to 1.92 in.)

|

- NOTICE:

- Make sure the bearing race is installed facing the proper direction.

| 31. INSTALL SECOND COAST BRAKE BAND ASSEMBLY |

Install the brake band to the case.

Install the pin to the brake band as shown in the illustration.

Install the E-ring to the pin.

| 32. INSTALL INPUT SHAFT OIL SEAL RING |

Coat the 3 new oil seal rings with ATF.

Squeeze the ends of the 3 oil seal rings together, and then install them to the input shaft groove.

- NOTICE:

- Do not squeeze the rings excessively.

- HINT:

- After installing the oil seal rings, check that they rotate smoothly.

| 33. INSTALL FORWARD CLUTCH PISTON SUB-ASSEMBLY |

Coat 2 new O-rings with ATF and install them to the forward clutch piston.

Text in Illustration*1

| O-Ring

|

Coat a new O-ring with ATF and install it to the input shaft.

Press the clutch piston into the input shaft with both hands to install it.

- NOTICE:

- Be careful not to damage the O-ring.

| 34. INSTALL FORWARD CLUTCH RETURN SPRING SUB-ASSEMBLY |

Install the piston return spring.

Place SST on the return spring, compress the return spring with a press, and then install the snap ring.

- SST

- 09350-30020(09350-07040,09350-07070)

- NOTICE:

- Make sure the end gap of the snap ring is not aligned with the return spring claw.

| 35. INSTALL FORWARD CLUTCH DISC SET |

Install the cushion plate.

Install the 5 plates, 5 discs and flange.

- Install in order:

- *1 - *2 - *1 - *2 - *1 - *2 - *1 - *2 - *1 - *2 - *1 - *2 - *3

Text in Illustration*1

| Plate

|

*2

| Disc

|

*3

| Flange

|

Using a screwdriver, install the snap ring.

Text in Illustration*1

| Protective tape

|

- NOTICE:

- Make sure the end gap of the snap ring is not aligned with the cutout portion of the input shaft sub-assembly.

- Be careful not to damage the input shaft sub-assembly.

- HINT:

- Tape the screwdriver tip before use.

| 36. SELECT FORWARD CLUTCH FLANGE |

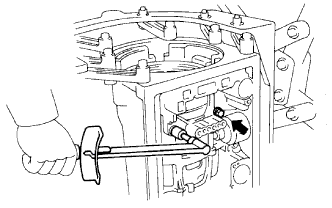

Using SST and a dial indicator, measure the piston stroke (A) of the clutch flange at both ends across the diameter while applying and releasing compressed air (392 kPa (4.0 kgf/cm2, 57 psi))

- SST

- 09350-30020(09350-06120)

- Standard piston stroke (A):

- 0.60 to 1.00 mm (0.0237 to 0.0394 in.)

If the piston stroke (A) is not as specified, select a flange of an appropriate thickness from the table below so that the measured value is within the standard range.

- Flange Thickness:

Mark

| Thickness

|

90

| 2.95 to 3.05 mm (0.117 to 0.120 in.)

|

91

| 3.15 to 3.25 mm (0.125 to 0.127 in.)

|

92

| 3.35 to 3.45 mm (0.132 to 0.135 in.)

|

93

| 3.55 to 3.65 mm (0.140 to 0.143 in.)

|

94

| 3.75 to 3.85 mm (0.148 to 0.151 in.)

|

95

| 3.95 to 4.05 mm (0.156 to 0.159 in.)

|

96

| 4.15 to 4.25 mm (0.164 to 0.167 in.)

|

97

| 4.35 to 4.45 mm (0.172 to 0.175 in.)

|

| 37. INSTALL DIRECT CLUTCH PISTON SUB-ASSEMBLY |

Coat 2 new O-rings with ATF and install them to the direct clutch piston.

Text in Illustration*1

| O-Ring

|

Press the clutch piston into the clutch drum with both hands to install it.

- NOTICE:

- Be careful not to damage the O-rings.

| 38. INSTALL DIRECT CLUTCH RETURN SPRING SUB-ASSEMBLY |

Install the direct clutch return spring.

Place SST on the return spring and compress the return spring with a press.

- SST

- 09350-30020(09350-07040)

Using SST, install the snap ring.

- SST

- 09350-30020(09350-07070)

- NOTICE:

- Be sure the end gap of the snap ring is not aligned with the return spring claw.

| 39. INSTALL DIRECT CLUTCH DISC SET |

Install the 3 plates and 3 discs.

Install the flange with the flat end facing downward.

- Install in order:

- *1 - *2 - *1 - *2 - *1 - *2 - *3

Text in Illustration*1

| Plate

|

*2

| Disc

|

*3

| Flange

|

Using a screwdriver, install the snap ring.

Text in Illustration*1

| Protective tape

|

- NOTICE:

- Make sure the end gap of the snap ring is not aligned with the cutout portion of the direct clutch drum.

- Be careful not to damage the direct clutch drum.

- HINT:

- Tape the screwdriver tip before use.

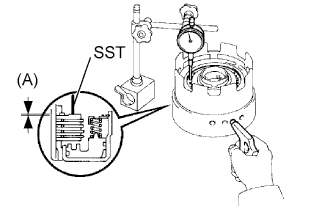

| 40. SELECT DIRECT CLUTCH FLANGE |

Place the direct clutch onto the overdrive support.

Using SST and a dial indicator, measure the piston stroke (A) of the clutch flange at both ends across the diameter while applying and releasing compressed air (186 to 206 kPa (1.9 to 2.1 kgf/cm2, 27 to 30 psi)).

- SST

- 09350-30020(09350-06120)

- Standard piston stroke (A):

- 0.40 to 0.70 mm (0.0158 to 0.0275 in.)

If the piston stroke (A) is not as specified, select a flange of an appropriate thickness from the table below so that the measured value is within the standard range.

- Flange Thickness:

Mark

| Thickness

|

53

| 3.25 to 3.35 mm (0.128 to 0.131 in.)

|

54

| 3.35 to 3.45 mm (0.132 to 0.135 in.)

|

55

| 3.45 to 3.55 mm (0.136 to 0.139 in.)

|

56

| 3.55 to 3.65 mm (0.140 to 0.143 in.)

|

57

| 3.65 to 3.75 mm (0.144 to 0.147 in.)

|

58

| 3.75 to 3.85 mm (0.148 to 0.151 in.)

|

| 41. INSTALL DIRECT CLUTCH ASSEMBLY |

Install the thrust washer to the input shaft.

Text in Illustration*1

| Thrust Washer

|

Install the direct clutch to the input shaft.

| 42. INSTALL FRONT PLANETARY RING GEAR SUB-ASSEMBLY |

Coat the bearing race and bearing with petroleum jelly and install them to the input shaft.

- Bearing and Bearing Race Diameter:

Item

| Inside

| Outside

|

Bearing Race E

| 25.98 mm (1.02 in.)

| 48.87 mm (1.92 in.)

|

Bearing E

| 25.94 to 26.07 mm (1.022 to 1.026 in.)

| 46.62 to 46.87 mm (1.835 to 1.845 in.)

|

Text in Illustration*1

| Bearing Race E

|

*2

| Bearing E

|

- NOTICE:

- Make sure the bearing and race are installed facing the proper directions.

Coat the bearing race with petroleum jelly and install it to the front planetary ring gear.

- Bearing Race Diameter:

Item

| Inside

| Outside

|

Bearing Race E

| 26.5 to 27.0 mm (1.044 to 1.062 in.)

| 47.02 mm (1.85 in.)

|

- NOTICE:

- Make sure the bearing race is installed facing the proper direction.

Align the teeth of the discs in the forward clutch.

Align the splines of the planetary ring gear with the teeth of the discs and install the planetary ring gear to the forward clutch.

| 43. INSTALL DIRECT CLUTCH ASSEMBLY WITH FORWARD CLUTCH ASSEMBLY |

Coat the bearing with petroleum jelly and install it to the ring gear.

- Bearing Diameter:

Item

| Inside

| Outside

|

Bearing F

| 35 to 35.3 mm (1.378 to 1.389 in.)

| 53.50 to 53.75 mm (2.107 to 2.116 in.)

|

Text in Illustration*1

| Bearing F

|

- NOTICE:

- Make sure the bearing is installed facing the proper direction.

Install the assembled direct clutch, forward clutch and front planetary ring gear to the transmission case.

Using a vernier caliper, measure the distance between the sun gear input drum and direct clutch drum as shown in the illustration.

- Standard distance:

- 5.3 to 7.3 mm (0.209 to 0.287 in.)

If the distance is not as specified, check for improper installation.

Coat the bearing with petroleum jelly and install it to the forward clutch.

- Bearing Diameter:

Item

| Inside

| Outside

|

Bearing D

| 33.55 to 33.80 mm (1.321 to 1.330 in.)

| 47.62 to 47.87 mm (1.875 to 1.884 in.)

|

- NOTICE:

- Make sure the bearing is installed facing the proper direction.

| 44. INSTALL SECOND COAST BRAKE PISTON ROD |

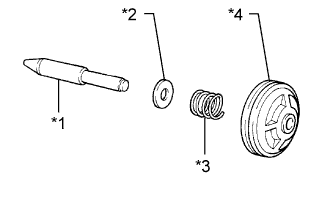

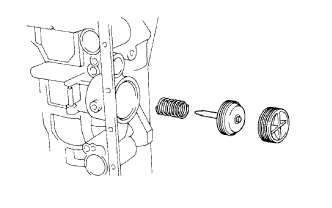

Install the washer plate, compression spring and piston to the piston rod.

Text in Illustration*1

| Piston Rod

|

*2

| Washer Plate

|

*3

| Compression Spring

|

*4

| Piston

|

Firmly press the piston down to compress the compression spring.

Install the E-ring.

| 45. INSTALL SECOND COAST BRAKE PISTON OIL SEAL RING |

Coat a new oil seal ring with ATF.

Spread the ends of the ring to install the oil seal ring to the piston groove. Then squeeze its ends together.

- NOTICE:

- Do not spread the ring ends excessively.

| 46. INSTALL SECOND COAST BRAKE PISTON ASSEMBLY |

Coat 2 new O-rings with ATF and install them to the second coast brake cover.

Install a new spring, piston assembly and cover to the case.

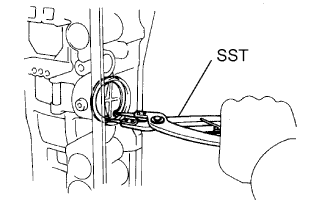

Using SST, install the snap ring.

- SST

- 09350-30020(09350-07060)

| 47. INSPECT PISTON STROKE OF SECOND COAST BRAKE |

Using a waterproof pen, place a mark on the second coast brake piston rod as shown in the illustration.

Text in Illustration*1

| Piston Rod

|

*2

| Mark

|

Using SST, measure the piston stroke while applying and releasing compressed air (392 kPa (4.0 kgf/cm2, 57 psi)).

- SST

- 09240-00020

- Standard piston stroke:

- 1.5 to 3.0 mm (0.0591 to 0.118 in.)

If the piston stroke is not as specified, inspect the brake band.

If the piston stroke is still not as specified, select a piston rod of an appropriate length from the table below so that the measured value is within the standard range.

- Piston Rod Length:

Groove Mark

| Length

|

Without

| 78.3 to 78.5 mm (3.083 to 3.090 in.)

|

With

| 79.8 to 80.0 mm (3.142 to 3.149 in.)

|

| 48. INSTALL OVERDRIVE BRAKE PISTON |

Coat 2 new O-rings with ATF and install them to the overdrive brake piston.

Text in Illustration*1

| O-Ring

|

Press the brake piston into the overdrive support with both hands to install it.

- NOTICE:

- Be careful not to damage the O-rings.

| 49. INSTALL OVERDRIVE BRAKE RETURN SPRING SUB-ASSEMBLY |

Install the return spring to the brake piston.

Place SST on the return spring and compress the return spring with a press.

- SST

- 09350-30020(09350-07030)

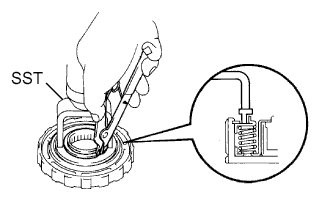

Using a screwdriver, install the snap ring.

Text in Illustration*1

| Protective Tape

|

- NOTICE:

- Make sure the end gap of the snap ring is not aligned with the cutout portion of the overdrive support.

- Be careful not to damage the overdrive support sub-assembly and return spring.

- HINT:

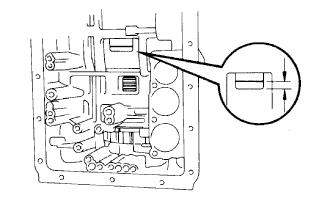

- After assembling the overdrive support assembly completely, align the position of the piston with A in the illustration.

- Align the end gap of the snap ring with B in the illustration.

- Make sure that the snap ring is not on top of the part of the return spring that prevents the snap ring from coming off. Check this in all 8 locations.

- Tape the screwdriver tip before use.

| 50. INSPECT PISTON OPERATION OF OVERDRIVE BRAKE |

Place the overdrive support assembly onto the direct clutch assembly.

Apply compressed air (392 kPa (4.0 kgf/cm2, 57 psi)) into the oil passage and check that the overdrive brake piston moves smoothly.

| 51. INSTALL OVERDRIVE CLUTCH DRUM OIL SEAL RING |

Coat 2 new oil seal rings with ATF.

Squeeze the ends of the 2 oil seal rings together, and then install them to the stator shaft groove.

- NOTICE:

- Do not squeeze the rings excessively.

- HINT:

- After installing the oil seal rings, check that they rotate smoothly.

| 52. INSTALL OVERDRIVE BRAKE ASSEMBLY |

Coat the bearing and bearing race with petroleum jelly and install them to the overdrive brake assembly.

- Bearing and Bearing Race Diameter:

Item

| Inside

| Outside

|

Bearing C

| 33.75 to 33.85 mm (1.329 to 1.332 in.)

| 49.8 to 50.3 mm (1.961 to 1.980 in.)

|

Bearing Race D

| 36.5 to 37 mm (1.44 to 1.45 in.)

| 50.75 to 50.95 mm (1.999 to 2.005 in.)

|

Text in Illustration*1

| Bearing C

|

*2

| Bearing Race D

|

- NOTICE:

- Make sure the bearing and race are installed facing the proper directions.

Coat the thrust washer with petroleum jelly and install it to the overdrive support.

- HINT:

- Make sure that the tab of the washer fits into the groove of the overdrive support.

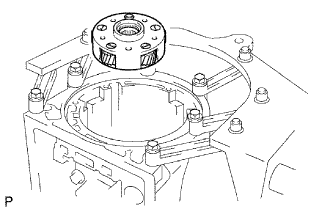

Using the 2 bolts of SST, aim the bolt and oil holes of the overdrive brake assembly toward the valve body side, and align them with the bolt holes of the transmission case. Then install the overdrive brake assembly.

- SST

- 09350-30020(09350-07020)

Temporarily install the 2 bolts.

Using SST, install the snap ring.

- SST

- 09350-30020(09350-07060)

- Standard distance A:

- 24 mm (0.945 in.)

- HINT:

- Install the snap ring with the open end facing toward the valve body.

Tighten the 2 bolts.

- Torque:

- 25 N*m{260 kgf*cm, 19 ft.*lbf}

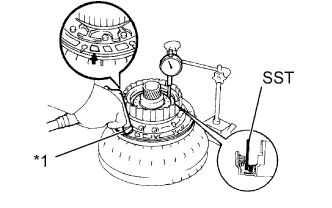

| 53. INSPECT OUTPUT SHAFT END PLAY |

Using a dial indicator, measure the end play of the output shaft while moving it by hand.

- Standard end play:

- 0.30 to 1.04 mm (0.0119 to 0.0409 in.)

If the end play is not as specified, check for improper installation.

Check that the output shaft rotates smoothly.

| 54. INSTALL OVERDRIVE BRAKE DISC SET |

Install the 4 plates, 4 discs and flange.

- Install in order:

- *1 - *2 -*1 - *2 - *1 - *2 - *1 - *2 - *3

Text in Illustration*1

| Plate

|

*2

| Disc

|

*3

| Flange

|

Using a screwdriver, install the snap ring.

Text in Illustration*1

| Protective Tape

|

- NOTICE:

- Be careful not to damage the transmission case.

- HINT:

- Tape the screwdriver tip before use.

| 55. SELECT OVERDRIVE BRAKE FLANGE |

Place SST and a dial indicator on the overdrive brake piston.

- SST

- 09350-30020(09350-06120)

Measure the stroke while applying and releasing compressed air (392 kPa (4.0 kgf/cm2, 57 psi))

- Standard piston stroke:

- 1.75 to 2.05 mm (0.0689 to 0.0807 in.)

If the piston stroke is not as specified, parts may have been assembled incorrectly. Check and reassemble again.

If the piston stroke is still outside the standard range, select a flange of an appropriate thickness from the table below so that the measured value is within the standard range.

- Flange Thickness:

Mark

| Thickness

|

33

| 3.25 to 3.35 mm (0.128 to 0.131 in.)

|

35

| 3.45 to 3.55 mm (0.136 to 0.139 in.)

|

36

| 3.55 to 3.65 mm (0.140 to 0.143 in.)

|

37

| 3.65 to 3.75 mm (0.144 to 0.147 in.)

|

38

| 3.75 to 3.85 mm (0.148 to 0.151 in.)

|

39

| 3.85 to 3.95 mm (0.152 to 0.155 in.)

|

40

| 3.95 to 4.05 mm (0.156 to 0.159 in.)

|

| 56. INSTALL OVERDRIVE PLANETARY RING GEAR FLANGE |

Install the ring gear flange to the overdrive planetary ring gear.

Using a screwdriver, install the snap ring.

Text in Illustration*1

| Protective Tape

|

- NOTICE:

- Be careful not to damage the overdrive planetary ring gear and the flange.

- HINT:

- Tape the screwdriver tip before use.

| 57. INSTALL OVERDRIVE PLANETARY RING GEAR |

Coat the bearing race with petroleum jelly and install it to the overdrive planetary ring gear flange.

- Bearing Race Diameter:

Item

| Inside

| Outside

|

Bearing Race C

| 37.1 to 37.3 mm (1.461 to 1.468 in.)

| 58.70 to 58.95 mm (2.311 to 2.320 in.)

|

Text in Illustration*1

| Bearing Race C

|

- NOTICE:

- Make sure the bearing race is installed facing the proper direction.

Install the ring gear.

| 58. INSTALL NO. 3 OVERDRIVE PLANETARY GEAR THRUST WASHER |

Install the thrust washer to the overdrive planetary gear with the grooves facing upward.

| 59. INSTALL OVERDRIVE 1-WAY CLUTCH |

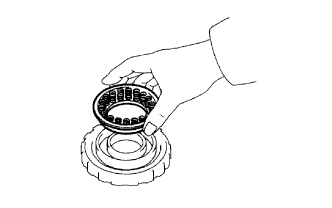

Install the 2 retainers to the 1-way clutch.

Install the 1-way clutch to the outer race with the flange of the 1-way clutch facing upward.

Text in Illustration*1

| Flange

|

Install the overdrive 1-way clutch and outer race to the overdrive planetary gear.

| 60. INSTALL OVERDRIVE RETAINING PLATE |

Install the retaining plate.

Using a screwdriver, install the snap ring.

Text in Illustration*1

| Protective Tape

|

- NOTICE:

- Be careful not to damage the overdrive planetary gear assembly and the plate.

- HINT:

- Tape the screwdriver tip before use.

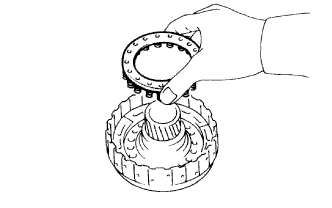

| 61. INSPECT OVERDRIVE 1-WAY CLUTCH |

Hold the overdrive direct clutch drum and turn the input shaft. Check that the input shaft can be turned clockwise freely and locks when turned counterclockwise.

Text in Illustration

| Lock

|

| Free

|

| 62. INSTALL OVERDRIVE DIRECT CLUTCH PISTON SUB-ASSEMBLY |

Coat 2 new O-rings with ATF and install them to the overdrive direct clutch piston.

Press the clutch piston into the clutch drum with both hands to install it.

- NOTICE:

- Be careful not to damage the O-rings.

| 63. INSTALL OVERDRIVE DIRECT CLUTCH RETURN SPRING SUB-ASSEMBLY |

Install the overdrive brake return spring to the overdrive direct clutch piston.

Place SST on the return spring and compress the return spring with a press.

- SST

- 09350-30020(09350-07040)

Using SST, install the snap ring.

- SST

- 09350-30020(09350-07070)

- NOTICE:

- Make sure the end gap of the snap ring is not aligned with the return spring claw.

| 64. INSTALL OVERDRIVE DIRECT CLUTCH DISC SET |

Install the 2 plates and 2 discs.

- Install in order:

- *1 - *2 - *1 - *2

Text in Illustration*1

| Plate

|

*2

| Disc

|

Install the flange with the flat end facing downward.

Using a screwdriver, install the snap ring.

Text in Illustration*1

| Protective Tape

|

- NOTICE:

- Be careful not to damage the overdrive direct clutch drum sub-assembly.

- HINT:

- Tape the screwdriver tip before use.

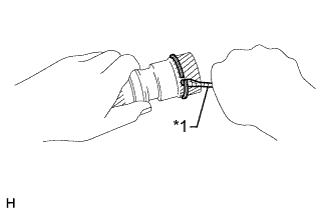

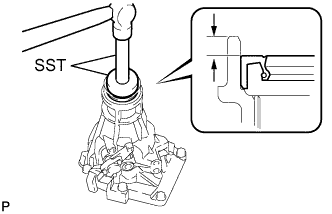

| 65. SELECT OVERDRIVE CLUTCH FLANGE |

Place the oil pump onto the torque converter clutch, and then place the overdrive direct clutch drum assembly onto the oil pump.

Using SST and a dial indicator, measure the overdrive direct clutch piston stroke while applying and releasing compressed air (392 kPa (4.0 kgf/cm2, 57 psi)).

- SST

- 09350-30020(09350-06120)

- Standard piston stroke:

- 1.85 to 2.15 mm (0.0728 to 0.0846 in.)

Text in Illustration*1

| Vinyl Tape

|

If the piston stroke is not as specified, parts may have been assembled incorrectly. Check and reassemble again.

If the piston stroke is still outside the standard range, select a flange of an appropriate thickness from the table below so that the measured value is within the standard range.

- Flange Thickness:

Mark

| Thickness

|

21

| 3.05 to 3.15 mm (0.1201 to 0.1240 in.)

|

20

| 3.15 to 3.25 mm (0.125 to 0.127 in.)

|

19

| 3.25 to 3.35 mm (0.128 to 0.131 in.)

|

18

| 3.35 to 3.45 mm (0.132 to 0.135 in.)

|

17

| 3.45 to 3.55 mm (0.136 to 0.139 in.)

|

16

| 3.55 to 3.65 mm (0.140 to 0.143 in.)

|

| 66. INSTALL OVERDRIVE DIRECT CLUTCH DRUM SUB-ASSEMBLY |

Align the teeth of the discs in the direct clutch assembly.

Install the direct clutch drum assembly to the overdrive planetary gear.

| 67. INSTALL OVERDRIVE PLANETARY GEAR ASSEMBLY WITH DIRECT CLUTCH ASSEMBLY AND OVERDRIVE 1-WAY CLUTCH ASSEMBLY |

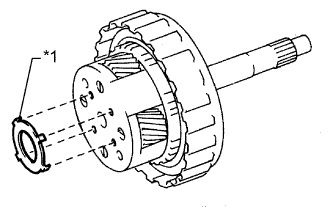

Coat the bearing with petroleum jelly and install it to the ring gear.

- Bearing Diameter:

Item

| Inside

| Outside

|

Bearing B

| 31.45 to 31.70 mm (1.230 to 1.248 in.)

| 49.1 to 49.4 mm (1.934 to 1.944 in.)

|

Text in Illustration*1

| Bearing B

|

- NOTICE:

- Make sure the bearing is installed facing the proper direction.

Coat the bearing race with petroleum jelly and install it to the planetary gear.

- Bearing Race Diameter:

Item

| Inside

| Outside

|

Bearing Race B

| 33.0 to 33.25 mm (1.300 to 1.309 in.)

| 49.9 to 50.4 mm (1.97 to 1.98 in.)

|

Text in Illustration*1

| Bearing Race B

|

- NOTICE:

- Make sure the bearing race is installed facing the proper direction.

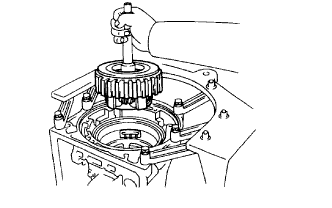

Install the overdrive planetary gear together with the overdrive direct clutch and 1-way clutch.

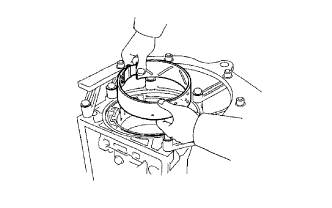

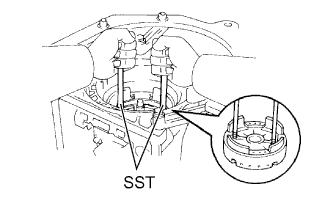

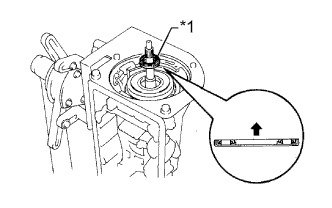

Place SST on the transmission case.

- SST

- 09350-36010(09350-06090)

Using a vernier caliper, measure the distance between the top of SST and the clutch drum.

- Standard distance:

- 15.5 to 16.5 mm (0.610 to 0.650 in.)

If the distance is not as specified, check for improper installation.

Coat the bearing with petroleum jelly and install it to the overdrive direct clutch.

- Bearing Diameter:

Item

| Inside

| Outside

|

Bearing A

| 29.04 to 29.25 mm (1.144 to 1.151 in.)

| 50.04 to 50.34 mm (1.970 to 1.981 in.)

|

Text in Illustration*1

| Bearing A

|

- NOTICE:

- Make sure the bearing is installed facing the proper direction.

| 68. INSTALL OIL PUMP ASSEMBLY |

Coat the bearing race with petroleum jelly and install it to the oil pump.

- Bearing Race Diameter:

Item

| Inside

| Outside

|

Bearing Race A

| 28.45 mm (1.12 in.)

| 47.1 to 47.35 mm (1.854 to 1.864 in.)

|

Text in Illustration*1

| Bearing Race A

|

- NOTICE:

- Make sure the bearing race is installed facing the proper direction.

Coat a new O-ring with ATF and install it to the pump body.

Slide the oil pump onto the input shaft, align the bolt holes of the oil pump assembly with the bolt holes of the transmission case and install the oil pump.

Hold the input shaft and lightly press the oil pump body to slide the oil seal rings toward the overdrive direct clutch drum.

- NOTICE:

- Do not forcefully push on the oil pump as the oil seal rings will stick to the direct clutch drum.

Install the 7 bolts.

- Torque:

- 21 N*m{215 kgf*cm, 16 ft.*lbf}

| 69. INSPECT INPUT SHAFT ROTATION |

Make sure the input shaft rotates smoothly.

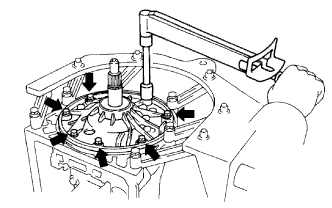

| 70. INSPECT INDIVIDUAL PISTON OPERATION |

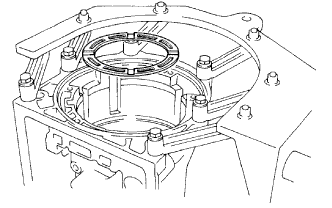

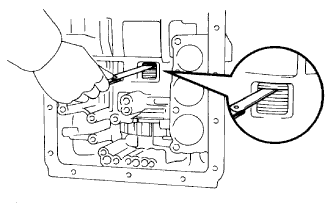

Check the operating sound while applying compressed air to the oil hole indicated in the illustration.

Text in Illustration*1

| Overdrive Direct Clutch (C1)

|

*2

| Direct Clutch (C2)

|

*3

| Forward Clutch (C3)

|

*4

| Overdrive Brake (B1)

|

*5

| Second Coast Brake (B2)

|

*6

| Second Brake (B3)

|

*7

| First and Reverse Brake (B4)

|

*8

| C-0 Accumulator Piston Hole

|

- HINT:

- When inspecting the overdrive direct clutch, check the operating sound with the C-0 accumulator piston hole closed.

- If there is no sound, disassemble and check the installation condition of the parts.

| 71. INSTALL MANUAL VALVE LEVER SHAFT OIL SEAL |

Using SST and a hammer, tap in 2 new oil seals.

- SST

- 09350-30020(09350-07110)

Coat the lips of the oil seals with MP grease.

| 72. INSTALL MANUAL VALVE LEVER SHAFT |

Install a new spacer to the manual valve lever.

Text in Illustration*1

| Spacer

|

*2

| Manual Valve Lever Shaft

|

*3

| Manual Valve Lever

|

Pass the manual valve lever shaft through the transmission case and manual valve lever to install it.

Using a hammer, tap in a new spring pin.

Align the manual valve lever indentation with the spacer hole and stake them with a punch.

Check that the shaft rotates smoothly.

| 73. INSTALL PARKING LOCK PAWL |

Install the E-ring to the parking lock pawl shaft.

Text in Illustration*1

| E-Ring

|

*2

| Parking Lock Pawl Shaft

|

*3

| Parking Lock Pawl

|

*4

| Spring

|

Install the parking lock pawl, shaft and spring.

| 74. INSTALL PARKING LOCK ROD SUB-ASSEMBLY |

Connect the parking lock rod to the manual valve lever to install it.

| 75. INSTALL PARKING LOCK PAWL BRACKET |

Install the parking lock pawl bracket to the transmission case with the 3 bolts.

- Torque:

- 7.4 N*m{75 kgf*cm, 65 in.*lbf}

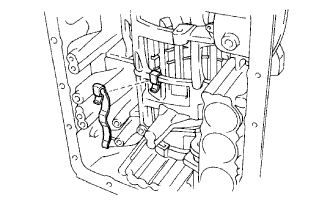

Shift the manual valve lever to the P position and confirm that the planetary ring gear is correctly locked by the parking lock pawl.

Text in Illustration*1

| Manual Valve Lever

|

*2

| Planetary Ring Gear

|

*3

| Parking Lock Pawl

|

| 76. INSTALL C-0 ACCUMULATOR PISTON |

Coat a new O-ring with ATF and install it to the piston.

Install the 2 springs and accumulator piston to the hole.

- Accumulator Spring Diameter:

Item

| Free Length

Outer Diameter

| Color

|

C-0 Inner Spring

| 46.0 mm (1.81 in.)

14.02 mm (0.552 in.)

| Yellow

|

C-0 Outer Spring

| 74.6 mm (2.94 in.)

20.9 mm (0.823 in.)

| Orange

|

| 77. INSTALL B-0 ACCUMULATOR PISTON |

Coat 2 new O-rings with ATF and install them to the piston.

Install the spring and accumulator piston to the hole.

- Accumulator Spring Diameter:

Item

| Free Length

Outer Diameter

| Color

|

B-0 Spring

| 62.0 mm (2.44 in.)

16.0 mm (0.630 in.)

| Green

|

| 78. INSTALL C-2 ACCUMULATOR PISTON |

Coat 2 new O-rings with ATF and install them to the piston.

Install the 2 springs and accumulator piston to the hole.

- Accumulator Spring Diameter:

Item

| Free Length

Outer Diameter

| Color

|

C-2 Inner Spring

| 42.06 mm (1.66 in.)

14.7 mm (0.579 in.)

| Pink

|

C-2 Outer Spring

| 68.53 mm (2.70 in.)

20.2 mm (0.795 in.)

| Blue

|

| 79. INSTALL B-2 ACCUMULATOR PISTON |

Coat 2 new O-rings with ATF and install them to the piston.

Install the spring and accumulator piston to the hole.

- Accumulator Spring Diameter:

Item

| Free Length

Outer Diameter

| Color

|

B-2 Spring

| 70.50 mm (2.78 in.)

19.9 mm (0.783 in.)

| Light Green

|

| 80. INSTALL CHECK BALL BODY |

Install the spring and check ball body.

Text in Illustration*1

| Spring

|

*2

| Check Ball Body

|

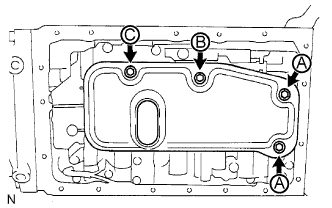

| 81. INSTALL TRANSMISSION VALVE BODY ASSEMBLY |

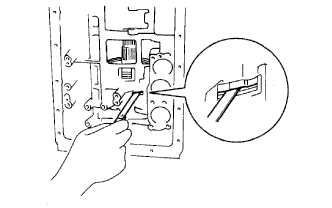

Install the valve body and align the groove of the manual valve with the pin of the manual valve lever.

Text in Illustration*1

| Manual Valve

|

*2

| Pin

|

*3

| Manual Valve Lever

|

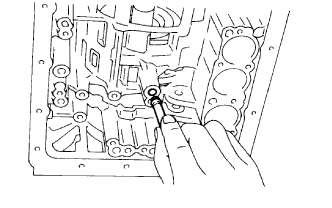

Install the 20 bolts.

- Torque:

- 11 N*m{110 kgf*cm, 8 ft.*lbf}

- HINT:

- Each bolt length is indicated below.

- 23 mm (0.906 in.) for A

- 28 mm (1.10 in.) for B

- 36 mm (1.42 in.) for C

| 82. INSTALL TRANSMISSION WIRE |

Coat a new O-ring with ATF and install it to the transmission wire.

Install the transmission wire to the case.

Install the stopper plate with the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

Connect the 4 connectors to the 4 shift solenoid valves.

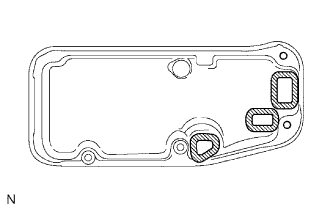

| 83. INSTALL VALVE BODY OIL STRAINER ASSEMBLY |

Install 3 new gaskets to the oil strainer.

Install the oil strainer with the 4 bolts.

- Torque:

- 11 N*m{110 kgf*cm, 8 ft.*lbf}

- HINT:

- Each bolt length is indicated below.

- 14 mm (0.55 in.) for A

- 20 mm (0.79 in.) for B

- 23 mm (0.91 in.) for C

| 84. INSTALL OIL CLEANER MAGNET |

Text in Illustration*1

| Magnet

|

Install the 3 magnets.

| 85. INSTALL AUTOMATIC TRANSMISSION OIL PAN SUB-ASSEMBLY |

Remove all old seal packing from the contact surfaces of the transmission case and oil pan.

- NOTICE:

- Be careful not to drop oil on the contact surfaces of the transmission case and oil pan.

Apply seal packing to the oil pan.

- Seal packing:

- Toyota Genuine Seal Packing 1281,

Three Bond 1281 or equivalent

- Seal diameter:

- 2 to 3 mm (0.0788 to 0.118 in.)

Install the oil pan with the 19 bolts.

- Torque:

- 7.4 N*m{75 kgf*cm, 65 in.*lbf}

Using a snap ring expander, install the snap ring.

Text in Illustration*1

| Snap Ring

|

*2

| Key

|

*3

| Sensor Rotor

|

Install the key to the output shaft.

Align the groove of the sensor rotor with the key and install the sensor rotor.

| 87. INSTALL SPEEDOMETER DRIVE GEAR |

Install the ball to the output shaft.

Text in Illustration*1

| Snap Ring

|

*2

| Key

|

*3

| Sensor Rotor

|

Align the groove of the speedometer drive gear with the ball and install the speedometer drive gear.

Using a snap ring expander, install the snap ring.

| 88. INSTALL AUTOMATIC TRANSMISSION EXTENSION HOUSING OIL SEAL |

Coat the lip of a new oil seal with MP grease.

Using SST and a hammer, tap in the oil seal.

- SST

- 09950-60010(09951-00580)

09950-70010(09951-07100)

- Standard depth:

- 5.8 to 6.2 mm (0.228 to 0.244 in.)

- NOTICE:

- Be careful not to damage the lip of the oil seal.

| 89. INSTALL EXTENSION HOUSING DUST DEFLECTOR |

Using a screwdriver and hammer, tap on a new dust deflector.

| 90. INSTALL EXTENSION HOUSING BUSH APPLY TUBE GASKET |

Install the gasket to the extension housing bush apply tube.

| 91. INSTALL EXTENSION HOUSING BUSH APPLY TUBE |

Install the extension housing bush apply tube together with the gasket to the extension housing.

| 92. INSTALL EXTENSION HOUSING SUB-ASSEMBLY |

Clean the threads of the bolts.

Apply adhesive to the 6 bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324,

Three Bond 1324 or equivalent

Install a new gasket and the extension housing to the transmission case with the 6 bolts.

- Torque:

- 34 N*m{345 kgf*cm, 25 ft.*lbf}

- HINT:

- Each bolt length is indicated below.

- 45 mm (1.77 in.) for A

- 35 mm (1.38 in.) for B

| 93. INSTALL AUTOMATIC TRANSMISSION HOUSING |

Clean the threads of the bolts and case with non-residue solvent.

Apply adhesive to the 6 bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324,

Three Bond 1324 or equivalent

Install the transmission housing with the 6 bolts.

- Torque:

- for 14 mm bolt:

- 34 N*m{345 kgf*cm, 25 ft.*lbf}

- for 17 mm bolt:

- 57 N*m{585 kgf*cm, 42 ft.*lbf}

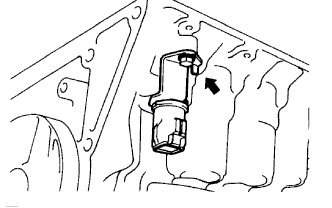

| 94. INSTALL SPEED SENSOR SP2 |

Coat a new O-ring with ATF and install it to the sensor.

Install the sensor with the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 95. INSTALL SPEEDOMETER SENSOR |

Coat a new O-ring with ATF and install it to the sensor.

Install the sensor with the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 96. INSTALL SPEED SENSOR NC0 |

Coat a new O-ring with ATF and install it to the sensor.

Install the speed sensor with the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 97. INSTALL OIL COOLER TUBE UNION |

Coat 2 new O-rings with ATF and install one to each tube union.

Text in Illustration*a

| 5 to 9°

|

*b

| -2 to 2°

|

Using a 19 mm union nut wrench, Install the 2 oil cooler tube unions.

- Torque:

- 29 N*m{300 kgf*cm, 22 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque value for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1003X.html).

| 98. INSTALL ATF TEMPERATURE SENSOR |

Install the bolt with the wire harness bracket.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

Coat a new O-ring with ATF and install it to the sensor.

Using a 19 mm union nut wrench, Install the ATF temperature sensor.

- Torque:

- 29 N*m{300 kgf*cm, 22 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque value for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1003X.html).

Connect the ATF temperature sensor clamp to the wire harness bracket.

| 99. INSTALL PARK/NEUTRAL POSITION SWITCH ASSEMBLY |

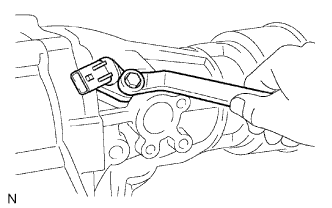

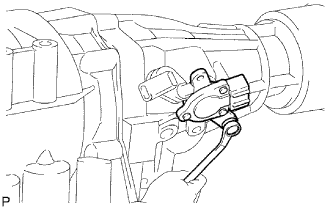

Install the park/neutral position switch to the manual valve lever shaft and temporarily install the adjusting bolt.

Install a new lock washer and the nut.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

Turn the control shaft lever LH clockwise until it stops, and then turn it counterclockwise 2 notches to set it to the N position.

Align the neutral basic line with the switch groove as shown in the illustration and tighten the adjusting bolt.

- Torque:

- 13 N*m{130 kgf*cm, 9 ft.*lbf}

Text in Illustration*1

| Groove

|

*2

| Neutral Basic Line

|

Using a screwdriver, bend the tabs of the lock washer.

| 100. INSTALL TRANSMISSION CONTROL SHAFT LEVER LH |

Install the control shaft lever with the washer and nut.

- Torque:

- 16 N*m{160 kgf*cm, 12 ft.*lbf}

| 101. INSTALL BREATHER HOSE |

Install the breather hose with the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

Install a new gasket and the drain plug.

- Torque:

- 20 N*m{205 kgf*cm, 15 ft.*lbf}