Front Propeller Shaft Assembly (For Tsam Made) -- Reassembly |

- NOTICE:

- When using a vise, place aluminum plates between the part and vise.

- When using a vise, do not overtighten it.

| 1. INSTALL UNIVERSAL JOINT SPIDER ASSEMBLY |

- HINT:

- Use the same procedure for both universal joint spiders.

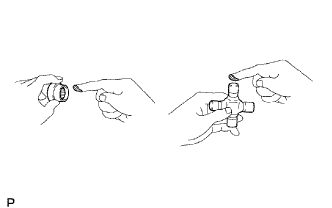

Apply MP grease to a new spider and 2 new spider bearings.

- NOTICE:

- Be careful not to apply too much grease.

|

Fit the spider into the flange yoke.

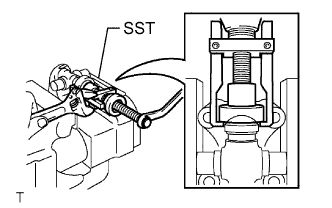

Using SST, install the 2 spider bearings to the spider.

- SST

- 09332-25010

|

Using SST, adjust the spider bearings so that: 1) the flange yoke does not overlap the snap ring grooves of the spider bearings; 2) the grooves are as wide as possible; and 3) the groove width on both sides is the same.

- SST

- 09332-25010

|

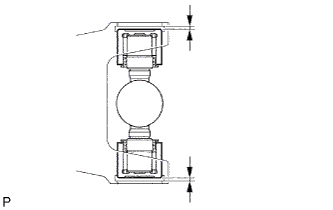

Install 2 new snap rings to the installed spider bearings. The snap rings must have equal thickness and allow 0 to 0.05 mm (0 to 0.00196 in.) of axial play.

- Standard Snap Ring Thickness:

Part No. Thickness Color 90080-52044 1.384 mm (0.0545 in.) Green 90080-52174 1.39 mm (0.0547 in.) Green 90080-52043 1.435 mm (0.0565 in.) Red 90080-52175 1.44 mm (0.0567 in.) Orange 90080-52041 1.486 mm (0.0585 in.) Black 90080-52176 1.49 mm (0.0587 in.) Black 90080-52042 1.511 mm (0.0595 in.) Copper 90080-52040 1.537 mm (0.0605 in.) Silver 90080-52177 1.54 mm (0.0606 in.) White 90080-52039 1.588 mm (0.0625 in.) Yellow 90080-52178 1.59 mm (0.0626 in.) Yellow 90080-52038 1.638 mm (0.0645 in.) Blue 90080-52179 1.64 mm (0.0646 in.) Red 90080-52180 1.69 mm (0.0665 in.) Blue

- NOTICE:

- New snap rings must be used.

- The snap ring thickness must be the same on both ends.

Using a plastic-faced hammer, tap the flange yoke until there is no clearance between the spider bearings and snap rings.

Text in Illustration *a Hammering Point

|

Align the matchmarks on the flange yoke and propeller shaft.

Install new spider bearings on the sleeve yoke side.

- HINT:

- Use the procedure described above.

| 2. INSPECT UNIVERSAL JOINT SPIDER ASSEMBLY |

Clamp the propeller shaft in a vise between aluminum plates.

- NOTICE:

- Do not overtighten the vise.

Check the spider bearings for wear or damage.

Check the axial play of each spider bearing by turning the yoke while holding the shaft tightly.

- Maximum bearing axial play:

- 0.05 mm (0.00196 in.)

|

| 3. INSTALL SLIDING SHAFT BOOT |

Temporarily install the boot to the propeller shaft with 2 new clamps.

Mount the propeller shaft in a soft vise.

Coat the splines of the propeller shaft with MP grease.

Align the matchmarks on the propeller shaft and sleeve yoke.

Install the sleeve yoke to the propeller shaft and connect the boot.

Secure one of the boot clamps to the boot.

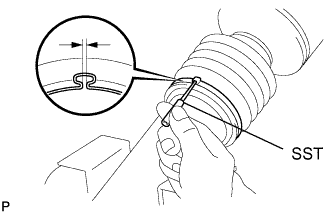

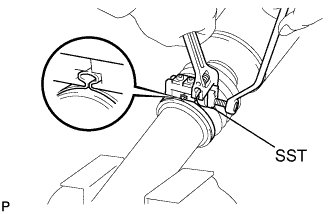

Place SST onto the boot clamp.

- SST

- 09521-24010

Tighten SST so that the boot clamp is pinched as shown in the illustration.

- NOTICE:

- Do not overtighten SST.

Using SST, adjust the clearance of the boot clamp.

- SST

- 09240-00020

- Standard clearance:

- 0.8 mm (0.0314 in.) or less

|

Secure the remaining boot clamp to the boot.

- HINT:

- Use the procedure described above.

| 4. INSPECT PROPELLER SHAFT GREASE FITTING DIRECTION |

- HINT:

- When replacing a spider bearing, be sure that the grease fitting hole is facing the direction shown in the illustration.

- Fill the grease fittings with MP grease.

| *1 | No. 1 Grease Fitting | *2 | No. 2 Grease Fitting |

| *a | Spider grease fitting assembly direction for front propeller shaft assembly | *b | Rear Side |