Front Propeller Shaft Assembly (For Tmt Made) -- Reassembly |

- NOTICE:

- When using a vise, place aluminum plates between the part and vise.

- When using a vise, do not overtighten it.

| 1. INSTALL UNIVERSAL JOINT SPIDER ASSEMBLY |

|

- HINT:

- Use the same procedure for both universal joint spiders.

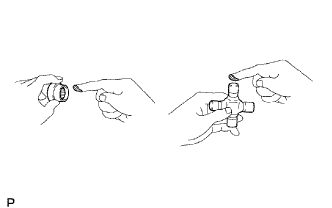

Apply MP grease to a new spider and 2 new spider bearings.

- NOTICE:

- Be careful not to apply too much grease.

Fit the spider into the flange yoke.

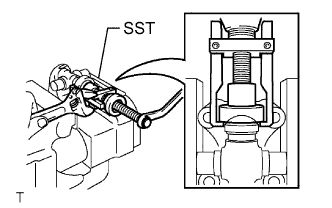

Using SST, install the 2 spider bearings to the spider.

- SST

- 09332-25010

|

Using SST, adjust the spider bearings so that: 1) the flange yoke does not overlap the snap ring grooves of the spider bearings; 2) the grooves are as wide as possible; and 3) the groove width on both sides is the same.

- SST

- 09332-25010

|

Install 2 new snap rings to the installed spider bearings. The snap rings must have equal thickness and allow 0 to 0.05 mm (0 to 0.00196 in.) of axial play.

- Standard Snap Ring Thickness :

Part No. Thickness Mark 90520-T0007 2.19 mm (0.0862 in.) F 90520-T0008 2.21 mm (0.0870 in.) G 90520-T0009 2.23 mm (0.0878 in.) H 90520-T0010 2.25 mm (0.0886 in.) J 90520-T0011 2.27 mm (0.0894 in.) K 90520-T0012 2.29 mm (0.0902 in.) 1 90520-T0013 2.31 mm (0.0909 in.) 2 90520-T0014 2.33 mm (0.0917 in.) 3 90520-T0015 2.35 mm (0.0925 in.) 4 90520-T0016 2.37 mm (0.0933 in.) 5 90520-T0017 2.39 mm (0.0941 in.) 6 90520-T0018 2.41 mm (0.0949 in.) 7 90520-T0019 2.43 mm (0.0957 in.) 8 90520-T0020 2.45 mm (0.0965 in.) N 90520-T0021 2.47 mm (0.0972 in.) 10 90520-T0022 2.49 mm (0.0980 in.) A 90520-T0023 2.51 mm (0.0988 in.) B 90520-T0024 2.53 mm (0.0996 in.) C 90520-T0025 2.55 mm (0.1004 in.) D 90520-T0026 2.57 mm (0.1012 in.) E

- NOTICE:

- New snap rings must be used.

- The snap ring thickness must be the same on both ends.

Using a plastic-faced hammer, tap the flange yoke until there is no clearance between the spider bearings and snap rings.

Text in Illustration *a Hammering Point

|

Align the matchmarks on the flange yoke and propeller shaft.

Install new spider bearings on the sleeve yoke side.

- HINT:

- Use the procedure described above.

| 2. INSPECT UNIVERSAL JOINT SPIDER ASSEMBLY |

Clamp the propeller shaft in a vise between aluminum plates.

- NOTICE:

- Do not overtighten the vise.

Check the spider bearings for wear or damage.

Check the axial play of each spider bearing by turning the yoke while holding the shaft tightly.

- Maximum bearing axial play:

- 0.05 mm (0.00196 in.)

|

| 3. INSPECT PROPELLER SHAFT GREASE FITTING DIRECTION |

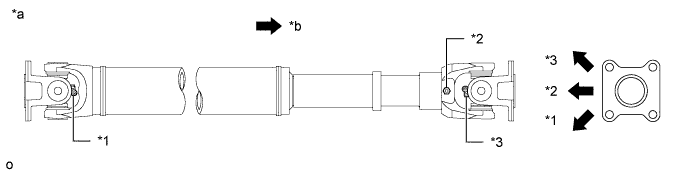

- HINT:

- When replacing a spider bearing, be sure that the grease fitting hole is facing the direction shown in the illustration.

- Fill the grease fittings with MP grease.

| *1 | No. 1 Grease Fitting | *2 | No. 2 Grease Fitting |

| *3 | No. 3 Grease Fitting | - | - |

| *a | Spider grease fitting assembly direction for front propeller shaft assembly | *b | Rear Side |