Engine -- On-Vehicle Inspection |

| 1. INSPECT AIR CLEANER FILTER ELEMENT |

Remove the air cleaner filter element.

Visually check that the air filter is not excessively damaged or oily.

If necessary, replace the air cleaner filter element.

| 2. INSPECT V-RIBBED BELT TENSIONER ASSEMBLY |

Turn the pulley, and check that the tensioner bearing moves smoothly and quietly.

If necessary, replace the tensioner pulley.Text in Illustration *a Turn

|

| 3. INSPECT NO. 1 IDLER PULLEY |

Idle the engine, and then stop the engine. Check that the fan and generator V belt is between the edges of the idler pulley.

Remove the fan and generator V belt.

Turn the pulley, and check that the idler bearing moves smoothly and quietly.

If necessary, replace the No. 1 idler pulley.Text in Illustration *a Turn

|

Install the fan and generator V belt.

| 4. CHECK VALVE LASH ADJUSTER NOISE |

Rev the engine several times. Check that the engine does not emit unusual noises.

If unusual noises occur, warm up the engine and idle it for more than 30 minutes. Then perform the inspection above again.

If any defects or problems are found during the inspection above, perform a lash adjuster inspection (HILUX_TGN26 RM00000447K00LX_01_0017.html).

| 5. INSPECT IGNITION TIMING |

Warm up and stop the engine.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

- NOTICE:

- Switch off all the accessories and the A/C before connecting the intelligent tester.

Start the engine and idle it.

Turn the intelligent tester main switch on.

Enter the following menus: Powertrain / Engine and ECT / Data List / IGN Advance.

- Standard ignition timing:

- 0 to 20° BTDC @ idle

- NOTICE:

- When checking the ignition timing, the transmission should be in neutral or park.

- HINT:

- Refer to the intelligent tester operator's manual for further details.

Check that the ignition timing advances immediately when the engine speed is increased.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Connect the TC and TE1.

Monitor IGN Advance.

Perform the Active Test.

- Standard ignition timing:

- 3 to 7° BTDC @ idle

- NOTICE:

- When checking the ignition timing, the transmission should be in neutral or park.

- HINT:

- Refer to the intelligent tester operator's manual for further details.

When not using the intelligent tester:

Using SST, connect a tachometer probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18030

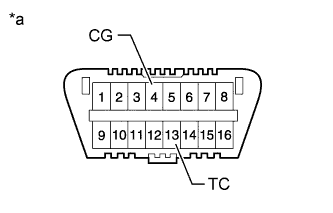

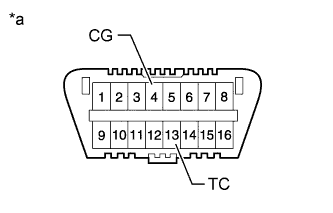

Text in Illustration *a Front view of DLC3 - NOTICE:

- Confirm the terminal number before connecting the probe. Connecting the wrong terminals can damage the engine.

- Turn off all electrical systems before connecting the probe.

Connect the tester probe of a timing light to the wire of the ignition coil connector for the No. 1 cylinder.

Start the engine and idle it.

Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

- SST

- 09843-18040

Text in Illustration *a Front view of DLC3 - NOTICE:

- When checking the ignition timing, the transmission should be in neutral.

- HINT:

- After connecting terminals TC and CG, the engine speed changes to between approximately 1000 and 1500 rpm for 5 seconds, and then returns to idle as the ECM checks that the ISC (Idle Speed Control) system operates properly.

- Inspect the ignition timing after the engine speed returns to idle.

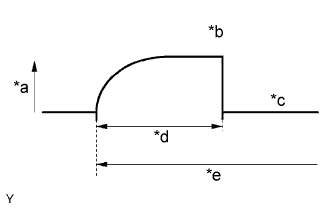

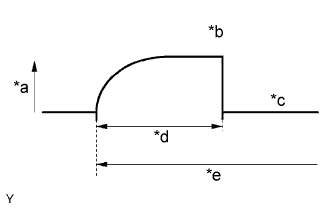

Text in Illustration *a Engine Speed *b Approx. 1000 to 1500 rpm *c Idle Speed *d 5 sec. *e Connect Terminals TC and CG Using the timing light, measure the ignition timing.

- Standard ignition timing:

- 3 to 7° BTDC @ idle

- NOTICE:

- Turn all the electrical systems and the A/C off.

- When checking the ignition timing, the transmission should be in neutral or park.

Remove SST from the DLC3.

Check the ignition timing.

- Standard ignition timing:

- 0 to 20° BTDC @ idle

Confirm that the ignition timing advances immediately when the engine speed is increased.

Turn the ignition switch off.

Disconnect the timing light from the engine.

| 6. INSPECT ENGINE IDLE SPEED |

Warm up and stop the engine.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

- NOTICE:

- Switch off all accessories and the air conditioning before connecting the intelligent tester.

Start the engine and idle it.

Turn the intelligent tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / Engine SPD.

- Standard idle speed:

- 600 to 700 rpm

- NOTICE:

- When checking the idle speed, the transmission should be in neutral.

- HINT:

- Refer to the intelligent tester operator's manual for further details.

Turn the ignition switch off.

Disconnect the intelligent tester from the DLC3.

When not using the intelligent tester:

Using SST, connect a tachometer tester probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18030

Text in Illustration *a Front view of DLC3 Start the engine and idle it.

Check the idle speed.

- Standard idle speed:

- 600 to 700 rpm

| 7. INSPECT IDLE SPEED CONTROL SYSTEM |

Warm up and stop the engine.

Check the idle speed control system.

Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

- SST

- 09843-18040

Text in Illustration *a Front view of DLC3 Start the engine and idle it.

- NOTICE:

- Confirm the terminal numbers before connecting them. Connecting the wrong terminals can damage the engine.

- Turn off all electrical systems before connecting the terminals.

- When checking the idle speed, the transmission should be in neutral.

After connecting terminals TC and CG, check that the engine speed changes to between approximately 1000 and 1500 rpm for 5 seconds, and then returns to idle.

If the result is not as specified, check the throttle body and wire harness, and check for DTCs (HILUX_TGN26 RM000000PDK0SXX.html) and wire harness.Text in Illustration *a Engine Speed *b Approx. 1000 to 1500 rpm *c Idle Speed *d 5 sec. *e Connect Terminals TC and CG

| 8. INSPECT COMPRESSION |

Warm up and stop the engine.

Check for DTCs (HILUX_TGN26 RM000000PDK0SXX.html).

Disconnect the 4 fuel injector connectors.

Remove the 4 spark plugs (HILUX_TGN26 RM000000SK7015X.html).

Check the cylinder compression pressure.

Insert a compression gauge into the spark plug hole.

Fully open the throttle.

While cranking the engine, measure the compression pressure.

- Standard compression pressure:

- 1230 kPa (12.5 kgf/cm2, 178 psi) or higher

- Minimum pressure:

- 880 kPa (9.0 kgf/cm2, 128 psi)

- Difference between each cylinder:

- 68 kPa (0.7 kgf/cm2, 9.9 psi) or less

- NOTICE:

- Use a fully-charged battery so the engine speed can be increased to 250 rpm or more.

- Inspect the other cylinders in the same way.

- Measure the compression in as short a time as possible.

- HINT:

- If adding oil increases the compression pressure, the piston rings and/or cylinder bore may be worn or damaged.

- If the pressure stays low, the valve may be stuck or seated improperly, or there may be leakage from the gasket.

Connect the 4 fuel injector connectors.

Install the 4 spark plugs (HILUX_TGN26 RM000000SK5017X.html).

Check for DTCs (HILUX_TGN26 RM000000PDK0SXX.html).

| 9. CHECK CO/HC |

Start and warm up the engine.

Run the engine at 2500 rpm for approximately 180 seconds, and then idle the engine.

Insert a CO/HC meter testing probe at least 40 cm (1.31 ft.) into the tailpipe.

Check the CO/HC concentration at idle.

- Standard idle CO concentration:

- 0 to 0.5%

- Standard idle HC concentration:

- Refer to applicable local regulation

If the CO/HC concentration is not as specified, perform troubleshooting in the order given below.

w/ Secondary Air Injection System:

Check the air fuel ratio sensor (HILUX_TGN26 RM00000142100ZX.html) and heated oxygen sensor operation (HILUX_TGN26 RM00000159K00IX.html).w/o Secondary Air Injection System:

Check the heated oxygen sensor operation (HILUX_TGN26 RM000001421012X.html).See the table below for possible causes, and then inspect and repair the applicable causes if necessary.

CO HC Problems Causes Normal High Rough idle - Faulty ignition:

- Incorrect timing

- Fouled, shorted or improperly gapped plugs

- Incorrect valve clearance

- Leaks in intake and exhaust valves

- Leaks in cylinders

Low High Rough idle

(Fluctuating HC reading)- Vacuum leaks:

- PCV hoses

- Intake manifold

- Throttle body

- Brake booster line

- Lean mixture causing misfire

High High Rough idle

(Black smoke from exhaust)- Restricted air cleaner filter element

- Plugged PCV valve

- Faulty SFI system:

- Faulty pressure regulator

- Defective engine coolant temperature sensor

- Defective mass air flow meter

- Faulty ECM

- Faulty injectors

- Faulty throttle position sensor

- Faulty ignition: