Engine Unit -- Installation |

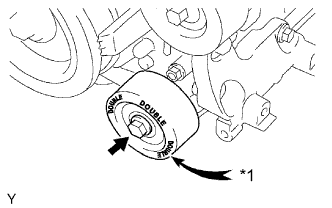

| 1. INSTALL NO. 1 IDLER PULLEY SUB-ASSEMBLY |

|

Install the No. 1 idler pulley with the bolt.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

Text in Illustration *1 "DOUBLE" - HINT:

- "DOUBLE" is marked on the No. 1 idler pulley to distinguish it from the No. 2 idler pulley.

| 2. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY |

w/ Idler Pulley Cover Plate:

Install the 2 idler pulley cover plates, 2 No. 2 idler pulleys and 2 No. 2 idler pulley cover plates with the 2 bolts.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

w/o Idler Pulley Cover Plate:

Install the 2 No. 2 idler pulleys and 2 No. 2 idler pulley cover plates with the 2 bolts.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

for Integrated Type:

Install the 2 No. 2 idler pulleys with the 2 bolts.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

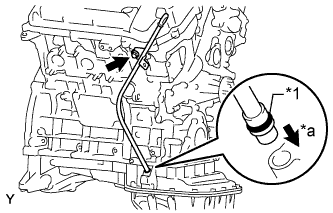

| 3. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE |

Install a new O-ring to the engine oil level dipstick guide.

Text in Illustration *1 New O-Ring *a Push

|

Apply a light coat of engine oil to the O-ring.

Push in the engine oil level dipstick guide end into the guide hole of the oil pan.

Install the engine oil level dipstick guide with the bolt.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

Install the engine oil level dipstick.

| 4. INSTALL IGNITION COIL ASSEMBLY |

Install the 6 ignition coils with the 6 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Connect the 6 ignition coil connectors.

| 5. INSTALL OIL FILLER CAP HOUSING |

Install a new gasket and the oil filler cap housing with the 2 nuts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

| 6. INSTALL OIL FILLER CAP SUB-ASSEMBLY |

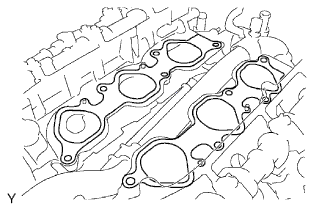

| 7. INSTALL INTAKE MANIFOLD |

Set 2 new gaskets on each cylinder head.

- NOTICE:

- Align the port holes of the gasket and cylinder head.

- Make sure the gaskets are installed facing the proper direction.

|

Set the intake manifold on the cylinder heads.

Install and uniformly tighten the 10 bolts in several passes.

- Torque:

- 26 N*m{265 kgf*cm, 19 ft.*lbf}

- HINT:

- Tighten the inner installation bolts of the intake manifold before tightening the outer bolts.

| 8. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY |

|

Temporarily install the V-ribbed belt tensioner with the 5 bolts.

Install the V-ribbed belt tensioner by tightening bolt 1 and then bolt 2.

- Torque:

- 36 N*m{367 kgf*cm, 27 ft.*lbf}

Tighten the other bolts.

- Torque:

- 36 N*m{367 kgf*cm, 27 ft.*lbf}

- Bolt Length:

Bolt Length

mm (in.)A 70 mm (2.76 in.) B 33 mm (1.30 in.)

Text in Illustration

Bolt A

Bolt B

| 9. INSTALL FRONT NO. 1 ENGINE MOUNTING BRACKET LH |

Install the front No. 1 engine mounting bracket LH with the 3 bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

| 10. INSTALL FRONT NO. 1 ENGINE MOUNTING BRACKET RH |

Install the front No. 1 engine mounting bracket RH with the 4 bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

| 11. INSTALL GENERATOR ASSEMBLY |

Install the generator with the 2 bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

Connect the generator wire with the nut and 2 bolts.

- Torque:

- for nut:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

- for bolt:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Install the terminal cap.

Connect the generator connector.

| 12. INSTALL NO. 2 PCV HOSE |

| 13. INSTALL PCV HOSE |

| 14. INSTALL HEATER WATER HOSE |

| 15. INSTALL ENGINE WIRE |