Dtc P0504 Brake Switch A / B Correlation

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK STOP LIGHT SWITCH ASSEMBLY (TERMINAL B VOLTAGE)

INSPECT STOP LIGHT SWITCH ASSEMBLY

CHECK ECM (STP AND ST1- VOLTAGE)

REPLACE STOP LIGHT SWITCH ASSEMBLY

REPLACE ECM

REPAIR OR REPLACE HARNESS OR CONNECTOR

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

DTC P0504 Brake Switch "A" / "B" Correlation |

DESCRIPTION

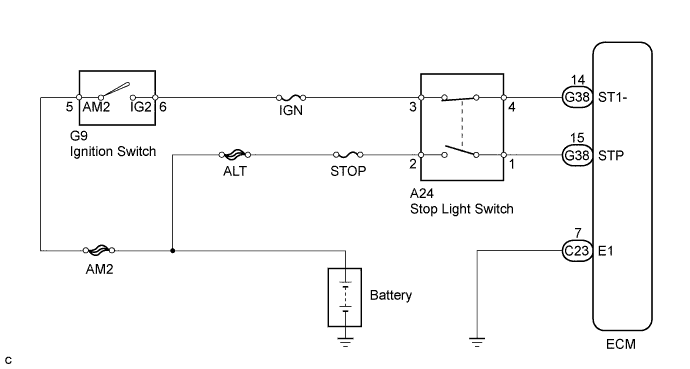

The stop light switch is a duplex system that transmits two signals: STP and ST1-. These two signals are used by the ECM to monitor whether or not the brake system is working properly. If the signals, which indicate that the brake pedal is being depressed and released, are detected simultaneously, the ECM interprets this as a malfunction in the stop light switch and stores the DTC.- HINT:

- The normal signal conditions are as shown in the table below.

Signal (ECM Terminal)

| Brake Pedal Released

| In Transition

| Brake Pedal Depressed

|

STP

| OFF

| ON

| ON

|

ST1-

| ON

| ON

| OFF

|

P0504DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

Depress and release brake pedal with ignition switch to ON

| Conditions (a), (b) and (c) continue for 0.5 seconds or more (1 trip detection logic):

(a) Ignition switch to ON.

(b) Brake pedal is released.

(c) The STP signal is off when the ST1- signal is off, or the STP signal is on when the ST1- signal is on.

| - Open or short in stop light switch signal circuit

- STOP fuse

- IGN fuse

- Stop light switch

- ECM

|

Related Data ListDTC No.

| Data List

|

P0504

| Stop Light Switch

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

- NOTICE:

- Inspect the fuses of circuits related to this system before performing the following inspection procedure.

- After replacing the ECM, the new ECM needs registration (HILUX_TGN26 RM0000012XK043X.html) and initialization (HILUX_TGN26 RM000000TIN04FX.html).

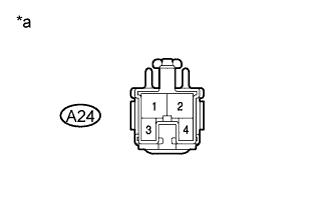

| 1.CHECK STOP LIGHT SWITCH ASSEMBLY (TERMINAL B VOLTAGE) |

Disconnect the stop light switch connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Condition

| Specified Condition

|

A24-2 - Body ground

| Always

| 11 to 14 V

|

A24-3 - Body ground

| Ignition switch ON

| 11 to 14 V

|

Text in Illustration*a

| Front view of wire harness connector

(to Stop Light Switch)

|

Reconnect the stop light switch connector.

| 2.INSPECT STOP LIGHT SWITCH ASSEMBLY |

Inspect the stop light switch assembly (HILUX_TGN26 RM0000018VE00SX.html).

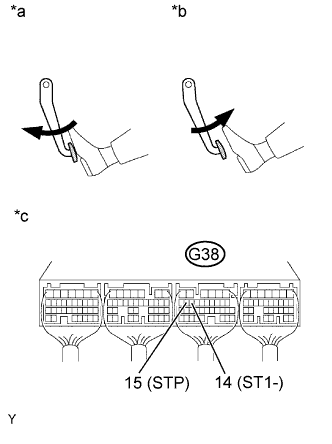

| 3.CHECK ECM (STP AND ST1- VOLTAGE) |

Disconnect the ECM connector.

Turn the ignition switch to ON.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Brake Pedal Condition

| Specified Condition

|

G38-14 (ST1-) - Body ground

| Released

| 11 to 14 V

|

Depressed

| 0 to 3 V

|

G38-15 (STP) - Body ground

| Released

| 0 to 3 V

|

Depressed

| 11 to 14 V

|

Text in Illustration*a

| Brake Pedal Depressed

|

*b

| Brake Pedal Released

|

*c

| Component with harness connected

(ECM)

|

Reconnect the ECM connector.

| 4.REPLACE STOP LIGHT SWITCH ASSEMBLY |

Replace the stop light switch assembly (HILUX_TGN26 RM0000018VF00UX.html).

Replace the ECM (HILUX_TGN26 RM0000043H100GX.html).

| 6.REPAIR OR REPLACE HARNESS OR CONNECTOR |

Repair or replace the harness or connector.

| 7.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the intelligent tester to the DLC3.

Clear the DTCs (HILUX_TGN26 RM000000PDK0TAX.html).

Turn the ignition switch off.

Turn the ignition switch to ON and turn the tester on.

Depress and release the brake pedal.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Confirm that the DTC is not output again.