Generator (For Denso Made) -- Reassembly |

| 1. INSTALL GENERATOR DRIVE END FRAME BEARING |

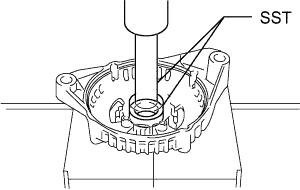

Using SST and a press, press in a new bearing.

- SST

- 09950-60010(09951-00520)

09950-70010(09951-07100)

|

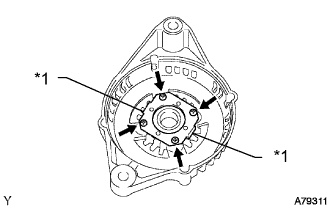

Align the claws of the bearing retainer with the grooves inside the generator drive end frame.

Text in Illustration *1 Claw

|

Install the bearing retainer with the 4 screws.

- Torque:

- 2.3 N*m{23 kgf*cm, 20 in.*lbf}

| 2. INSTALL GENERATOR ROTOR ASSEMBLY |

Install the rotor and washer to the drive end frame.

| 3. INSTALL GENERATOR COIL ASSEMBLY |

Using a 21 mm deep socket wrench and press, slowly press on the generator coil.

Text in Illustration *1 21 mm Deep Socket Wrench

|

Install the generator coil with the 4 through bolts.

- Torque:

- 5.9 N*m{60 kgf*cm, 52 in.*lbf}

| 4. INSTALL GENERATOR BRUSH HOLDER ASSEMBLY |

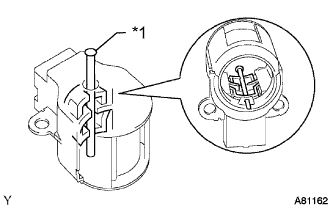

While pushing the 2 brushes into the generator brush holder, insert a pin with a diameter of 1.0 mm (0.0394 in.) into the brush holder hole.

Text in Illustration *1 Pin

|

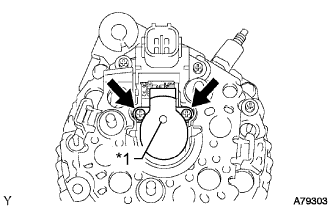

Install the brush holder with the 2 screws.

- Torque:

- 1.8 N*m{18 kgf*cm, 16 in.*lbf}

|

Pull out the pin from the brush holder.

Text in Illustration *1 Pin

| 5. INSTALL TERMINAL INSULATOR |

| 6. INSTALL GENERATOR REAR END COVER |

Install the generator rear end cover with the 3 nuts.

- Torque:

- 4.6 N*m{46 kgf*cm, 40 in.*lbf}

| 7. INSTALL GENERATOR WITH CLUTCH PULLEY |

Install the pulley by hand.

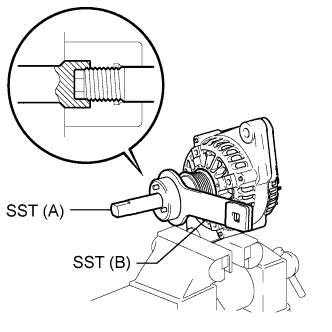

Mount generator in a vise between aluminum plates.

Install SST (A) and (B) to the generator with clutch pulley as shown in the illustration.

- SST

- 09820-63021

- NOTICE:

- Securely attach SST to the generator with clutch pulley and generator rotor shaft.

|

Use a wrench to hold SST (A) and turn SST (B) clockwise to tighten the generator with clutch pulley.

- Torque:

- without SST:

- 111 N*m{1127 kgf*cm, 81 ft.*lbf}

- with SST:

- 83 N*m{844 kgf*cm, 61 ft.*lbf}

Text in Illustration *1 Fulcrum Length *a Hold

Turn - NOTICE:

- Be careful as the generator with clutch pulley or generator rotor shaft may be damaged if the position of SST is not securely maintained while performing this operation.

- HINT:

- Use a torque wrench with a fulcrum length of 300 mm (11.8 in.). When using a torque wrench with a fulcrum length that is not 300 mm (11.8 in.), calculate the torque specification for the torque wrench and SST based on the "without SST" torque specification (HILUX_TGN26 RM000004QR1003X.html).

- Make sure SST and the wrench are connected in a straight line.

|

Remove SST from the generator.

Check that the generator pulley rotates smoothly.

Install a new generator pulley cap.