Dtc P2769 Torque Converter Clutch Solenoid Circuit Low (Shift Solenoid Valve Sl)

Drivetrain. Hilux. Tgn26, 36 Kun25, 26, 35, 36 Ggn25

DESCRIPTION

MONITOR DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

INSPECT TRANSMISSION WIRE (SHIFT SOLENOID VALVE SL)

CHECK HARNESS AND CONNECTOR (SHIFT SOLENOID VALVE SL - ECM)

INSPECT SHIFT SOLENOID VALVE SL

DTC P2769 Torque Converter Clutch Solenoid Circuit Low (Shift Solenoid Valve SL) |

DTC P2770 Torque Converter Clutch Solenoid Circuit High (Shift Solenoid Valve SL) |

DESCRIPTION

The shift solenoid valve SL is turned on and off by signals from the ECM to control the hydraulic pressure acting on the lock-up relay valve, which then controls the operation of the lock-up clutch.DTC Code

| DTC Detection Condition

| Trouble Area

|

P2769

| ECM detects short in shift solenoid valve SL circuit (once) when shift solenoid valve SL is operated (1-trip detection logic)

| - Short in shift solenoid valve SL circuit

- Shift solenoid valve SL

- ECM

|

P2770

| ECM detects open in shift solenoid valve SL circuit (once) when shift solenoid valve SL is not operated (1-trip detection logic)

| - Open in shift solenoid valve SL circuit

- Shift solenoid valve SL

- ECM

|

Fail-safe function:If the ECM detects a malfunction, it turns the shift solenoid valve SL off.

MONITOR DESCRIPTION

Torque converter lock-up is controlled by the ECM based on engine rpm, engine load, engine temperature, vehicle speed, transmission temperature, and shift position selection. The ECM determines the lock-up status of the torque converter by comparing the engine rpm (NE) to the input rpm (NC0). The ECM calculates the actual transmission gear by comparing the input rpm (NC0) to the output rpm (SP2). When conditions are appropriate, the ECM requests "lock-up" by applying control voltage to the shift solenoid valve SL. When the shift solenoid valve SL is opened, the shift solenoid valve SL applies pressure to the lock-up relay valve and locks the torque converter clutch. If the ECM detects an open or short in the shift solenoid valve SL circuit, the ECM interprets this as a fault in the shift solenoid valve SL or its circuit. The ECM will illuminate the MIL and store a DTC.

WIRING DIAGRAM

INSPECTION PROCEDURE

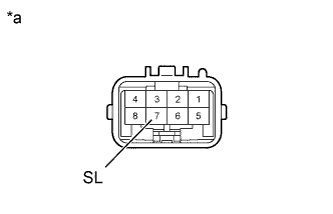

| 1.INSPECT TRANSMISSION WIRE (SHIFT SOLENOID VALVE SL) |

Disconnect the transmission wire connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

7 (SL) - Body ground

| 20°C (68°F)

| 11 to 15 Ω

|

Text in Illustration*a

| Component without harness connected

(Transmission Wire)

|

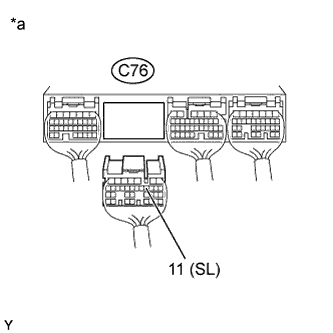

| 2.CHECK HARNESS AND CONNECTOR (SHIFT SOLENOID VALVE SL - ECM) |

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

C76-11 (SL) - Body ground

| 20°C (68°F)

| 11 to 15 Ω

|

Text in Illustration*a

| Rear view of wire harness connector

(to ECM)

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

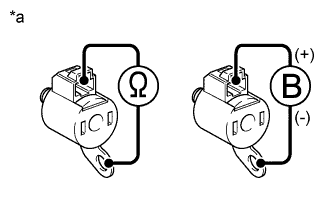

| 3.INSPECT SHIFT SOLENOID VALVE SL |

Remove shift solenoid valve SL.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

Shift solenoid valve SL connector terminal - Shift solenoid valve SL body

| 20°C (68°F)

| 11 to 15 Ω

|

Apply 12 V battery voltage to the shift solenoid valve and check that the valve moves and makes an operating noise.

- OK:

Measurement Condition

| Specified Condition

|

- Battery positive (+) → Shift solenoid valve SL connector

- Battery negative (-) → Shift solenoid valve SL body

| Valve moves and makes an operating noise

|

Text in Illustration*a

| Component without harness connected

(Shift Solenoid Valve SL)

|