Dtc P0327 Knock Sensor 1 Circuit Low Input (Bank 1 Or Single Sensor)

DESCRIPTION

MONITOR DESCRIPTION

CONFIRMATION DRIVING PATTERN

WIRING DIAGRAM

INSPECTION PROCEDURE

READ DTC OUTPUT (CHECK KNOCK SENSOR CIRCUIT)

CHECK HARNESS AND CONNECTOR (CONNECTOR - ECM)

INSPECT ECM (VOLTAGE)

INSPECT KNOCK SENSOR

CHECK HARNESS AND CONNECTOR (CONNECTOR - KNOCK SENSOR)

DTC P0327 Knock Sensor 1 Circuit Low Input (Bank 1 or Single Sensor) |

DTC P0328 Knock Sensor 1 Circuit High Input (Bank 1 or Single Sensor) |

DTC P0332 Knock Sensor 2 Circuit Low Input (Bank 2) |

DTC P0333 Knock Sensor 2 Circuit High Input (Bank 2) |

DESCRIPTION

Flat type knock sensors (non-resonant type) have structures that can detect vibrations between approximately 6 kHz and 15 kHz.Knock sensors are fitted onto the engine block to detect engine knocking.The knock sensor contains a piezoelectric element which generates a voltage when it becomes deformed.The voltage is generated when the engine block vibrates due to knocking. Any occurrence of engine knocking can be suppressed by delaying the ignition timing.DTC Code

| DTC Detection Condition

| Trouble Area

|

P0327

P0332

| The output voltage of the knock sensor is below 0.5 V (1 trip detection logic).

| - Short in knock sensor circuit

- Knock sensor

- ECM

|

P0328

P0333

| The output voltage of the knock sensor is higher than 4.5 V (1 trip detection logic).

| - Open in knock sensor circuit

- Knock sensor

- ECM

|

- HINT:

- When any of DTCs P0327, P0328, P0332 and P0333 are stored, the ECM enters fail-safe mode. During fail-safe mode, the ignition timing is delayed to its maximum retardation. Fail-safe mode continues until the ignition switch is turned off.

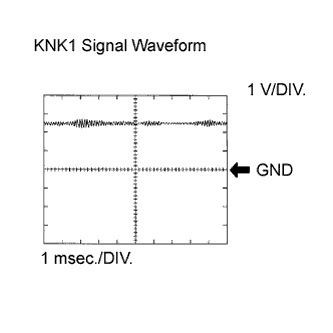

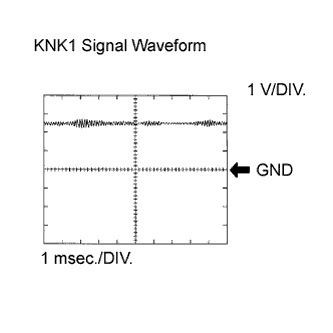

Reference: Inspection using an oscilloscope The correct waveform is as shown.

The correct waveform is as shown.Item

| Content

|

Terminal

| KNK1 - EKNK

KNK2 - EKN2

|

Equipment Setting

| 1 V/DIV.

1 msec./DIV.

|

Condition

| Engine speed maintained at 4000 rpm with warm engine

|

MONITOR DESCRIPTION

If the output voltage transmitted by the knock sensor remains low or high for 1 second or more, the ECM interprets this as a malfunction in the sensor circuit, and stores a DTC.The monitor for DTCs P0327, P0328, P0332 and P0333 begins to run when 5 seconds have elapsed since the engine was started.If the malfunction is not repaired successfully, DTC P0327, P0328, P0332 or P0333 is stored 5 seconds after the engine is next started.

CONFIRMATION DRIVING PATTERN

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to ON and turn the tester on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC operation).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON and turn the tester on.

- Start the engine and wait 5 minutes.

- Enter the following menus: Powertrain / Engine and ECT / DTC.

- Read the pending DTCs.

- HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

- Input the DTC: P0327, P0328, P0332 or P0333.

- Check the DTC judgment result.

Tester Display

| Description

|

NORMAL

| - DTC judgment completed

- System normal

|

ABNORMAL

| - DTC judgment completed

- System abnormal

|

INCOMPLETE

| - DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

|

N/A

| - Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

|

- HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, idle the engine for 5 minutes and check the DTC judgment result again.

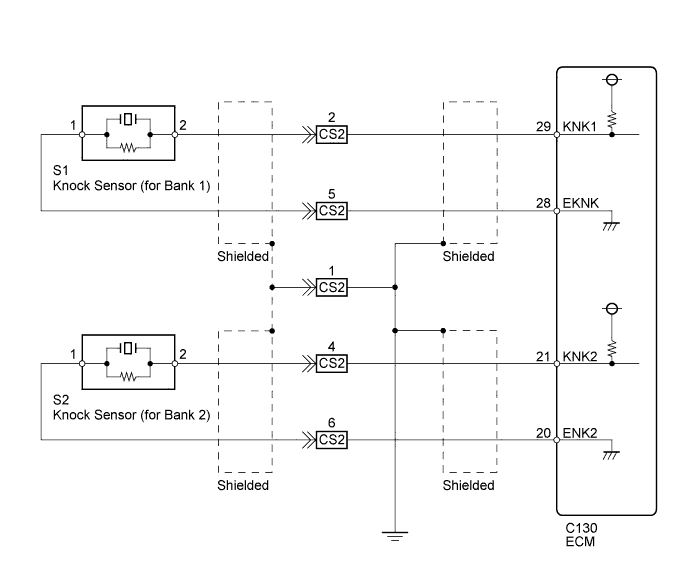

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- DTCs P0327 and P0328 are for the bank 1 knock sensor circuit.

- DTCs P0332 and P0333 are for the bank 2 knock sensor circuit.

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

- Bank 1 refers to the bank that includes No. 1 cylinder*.

*: The No. 1 cylinder is the cylinder which is farthest from the transmission.

- Bank 2 refers to the bank that does not include No. 1 cylinder.

| 1.READ DTC OUTPUT (CHECK KNOCK SENSOR CIRCUIT) |

Disconnect the CS2 connector.

Using lead wires, connect the connectors as follows:

Male Connector - Female Connector

|

Terminal 2 - Terminal 4

|

Terminal 5 - Terminal 6

|

Terminal 4 - Terminal 2

|

Terminal 6 - Terminal 5

|

Warm up the engine.

Run the engine at 3000 rpm for 10 seconds or more.

Connect the intelligent tester to the DLC3.

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

ResultResult

| Proceed to

|

DTC is same as when vehicle brought in

(for example, P0327 and P0328 are output again, or P0332 and P0333 are output again)

| A

|

DTC is different from when vehicle brought in

(for example, P0327 and P0328 are output at first, but then P0332 and P0333 are output, or vice versa)

| B

|

Text in Illustration*1

| Knock Sensor

|

*2

| ECM

|

*a

| Male connector

|

*b

| Female connector

|

| 2.CHECK HARNESS AND CONNECTOR (CONNECTOR - ECM) |

Disconnect the CS2 connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

CS2 female connector 2 - C130-29 (KNK1)

| Always

| Below 1 Ω

|

CS2 female connector 5 - C130-28 (EKNK)

| Always

| Below 1 Ω

|

CS2 female connector 4 - C130-21 (KNK2)

| Always

| Below 1 Ω

|

CS2 female connector 6 - C130-20 (EKN2)

| Always

| Below 1 Ω

|

CS2 female connector 2 or C130-29 (KNK1) - Body ground

| Always

| 10 kΩ or higher

|

CS2 female connector 5 or C130-28 (EKNK) - Body ground

| Always

| 10 kΩ or higher

|

CS2 female connector 4 or C130-21 (KNK2) - Body ground

| Always

| 10 kΩ or higher

|

CS2 female connector 6 or C130-20 (EKN2) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

Disconnect the CS2 connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

CS2 female connector 2 - 5

| Ignition switch ON

| 4.5 to 5.5 V

|

CS2 female connector 4 - 6

| Ignition switch ON

| 4.5 to 5.5 V

|

Text in Illustration*a

| Front view of wire harness connector

(to ECM Wire)

|

*b

| Female

|

Disconnect the CS2 connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

CS2 male connector 2 - 5

| 20°C (68°F)

| 120 to 280 kΩ

|

CS2 male connector 4 - 6

| 20°C (68°F)

| 120 to 280 kΩ

|

Text in Illustration*a

| Front view of wire harness connector

(to Knock Sensor Wire)

|

*b

| Male

|

| 5.CHECK HARNESS AND CONNECTOR (CONNECTOR - KNOCK SENSOR) |

- HINT:

- If DTC P0327 or P0328 has changed to P0332 or P0333, check the knock sensor circuit on the right bank side.

- If DTC P0332 or P0333 has changed to P0327 or P0328, check the knock sensor circuit on the left bank side.

Disconnect the CS2 connector.

Disconnect the knock sensor connectors.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

CS2 male connector 2 - S1-2

| Always

| Below 1 Ω

|

CS2 male connector 5 - S1-1

| Always

| Below 1 Ω

|

CS2 male connector 4 - S2-2

| Always

| Below 1 Ω

|

CS2 male connector 6 - S2-1

| Always

| Below 1 Ω

|

CS2 male connector 2 or S1-2 - Body ground

| Always

| 10 kΩ or higher

|

CS2 male connector 5 or S1-1 - Body ground

| Always

| 10 kΩ or higher

|

CS2 male connector 4 or S2-2 - Body ground

| Always

| 10 kΩ or higher

|

CS2 male connector 6 or S2-1 - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|