Engine Unit -- Installation |

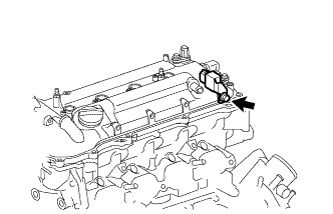

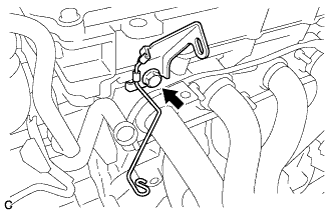

| 1. INSTALL RADIO SETTING CONDENSER |

Install the radio setting condenser with the bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

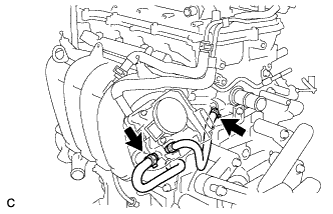

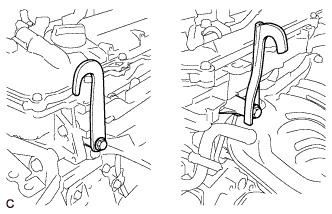

| 2. INSTALL THERMOSTAT |

Install a new gasket on the thermostat.

Install the thermostat to the water inlet with the jiggle valve upward.

- HINT:

- The jiggle valve may be set to within 10° on either side of the indicated position.

|

| 3. INSTALL WATER INLET |

Install the water inlet with the 2 nuts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

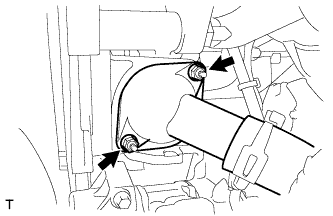

| 4. INSTALL INLET WATER HOSE |

Install the inlet water hose with the 2 clamps.

|

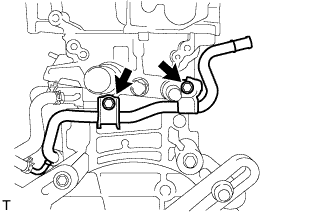

| 5. INSTALL WATER BY-PASS HOSE |

Install the water by-pass hose with the clamp.

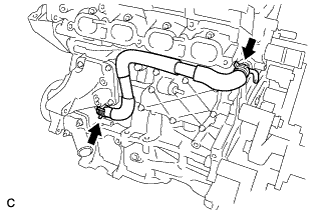

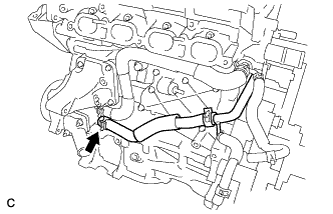

| 6. INSTALL NO. 1 WATER BY-PASS PIPE |

Install the No. 1 water by-pass pipe with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 16 ft.*lbf}

|

| 7. CONNECT NO. 3 WATER BY-PASS HOSE |

Connect the No. 3 water by-pass hose to the inlet water housing.

|

| 8. INSTALL VENTILATION HOSE |

Install the ventilation hose.

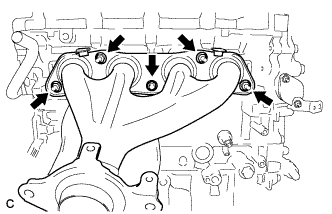

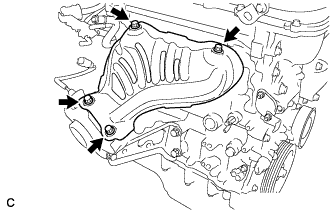

| 9. INSTALL EXHAUST MANIFOLD |

Install a new gasket onto the exhaust manifold.

|

Install the exhaust manifold with the 5 nuts.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

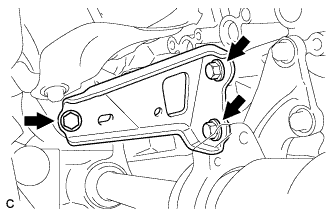

| 10. INSTALL MANIFOLD STAY |

Install the manifold stay with the 3 bolts.

- Torque:

- 43 N*m{439 kgf*cm, 32 ft.*lbf}

|

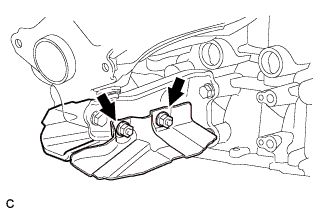

Install the 2 drive shaft heat insulator sub-assemblies with the 2 nuts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

|

| 11. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

Install the No. 1 exhaust manifold heat insulator with the 4 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

|

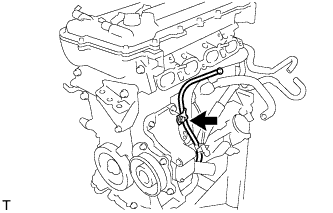

| 12. INSTALL OIL LEVEL DIPSTICK SUB-ASSEMBLY |

Apply engine oil to a new O-ring.

|

Install the oil level dipstick with the bolt through the new O-ring.

- Torque:

- 21 N*m{214 kgf*cm, 16 ft.*lbf}

| 13. INSTALL IGNITION COIL ASSEMBLY |

Install the 4 ignition coils with the 4 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

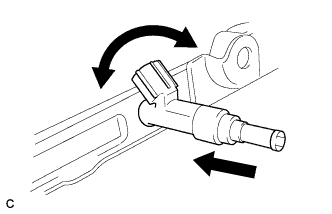

| 14. INSTALL FUEL INJECTOR ASSEMBLY |

Install 4 new injector vibration insulators to the 4 fuel injector assemblies.

|

Install 4 new injector vibration insulators to the 4 fuel injector assemblies.

Apply a light coat of gasoline or spindle oil to the contact surfaces of the the O-rings of the fuel injector assemblies.

While turning the fuel injector assembly left and right, install it onto the fuel delivery pipe sub-assembly.

- NOTICE:

- Do not twist the O-ring.

- After installing the fuel injectors, check that they turn smoothly.

|

| 15. INSTALL NO. 1 DELIVERY PIPE SPACER |

Install the 2 No. 1 delivery pipe spacers onto the cylinder head.

Text in Illustration *a Delivery Pipe Side *b Cylinder Head Side - NOTICE:

- Install the No. 1 delivery pipe spacers in the correct direction.

|

| 16. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY |

Install the fuel delivery pipe sub-assembly with the 4 fuel injector assemblies, then temporarily install the 2 bolts.

- NOTICE:

- Do not drop the fuel injectors when installing the fuel delivery pipe sub-assembly.

- Check that the fuel injector assemblies rotate smoothly after installing the fuel delivery pipe sub-assembly.

|

Tighten the 2 bolts to the specified torque.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

Install the bolt to secure the fuel delivery pipe sub-assembly.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

Install the wire harness bracket with the bolt.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

|

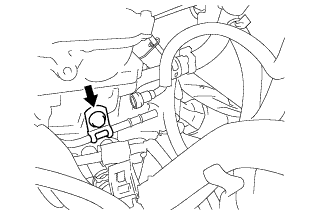

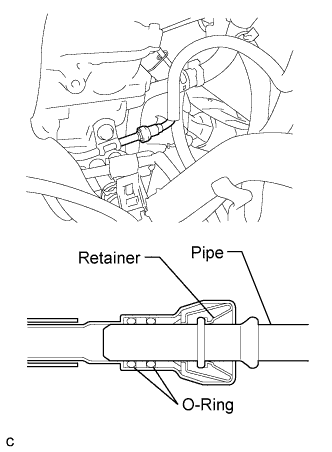

| 17. CONNECT FUEL TUBE SUB-ASSEMBLY |

Insert the fuel tube sub-assembly connector into the fuel delivery pipe until a "click" sound can be heard.

- NOTICE:

- Check that there are no scratches or foreign matter around the contact surfaces of the fuel tube connector and pipe before performing this work.

- After connecting the fuel tube, check that the fuel tube connector and pipe are securely connected by pulling on them.

|

Install a new No. 2 fuel pipe clamp (Type B).

|

Install a new No. 2 fuel pump clamp (Type A).

|

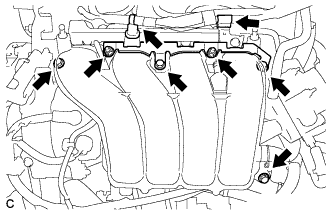

| 18. INSTALL INTAKE MANIFOLD |

Install a new gasket to the intake manifold.

Install the intake manifold and intake manifold stay with the 4 bolts and 2 nuts.

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

|

Connect the 2 water by-pass hoses.

|

Connect the ventilation hose to the intake manifold.

Install the air tube with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Install the wire harness bracket.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

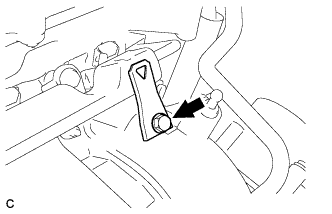

| 19. INSTALL FAN BELT ADJUSTING BAR |

Install the fan belt adjusting bar with the bolt.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

| 20. INSTALL ENGINE HANGER |

Remove the bolt and wire harness bracket.

|

Install the 2 engine hangers with the 2 bolts.

- Torque:

- 43 N*m{439 kgf*cm, 32 ft.*lbf}

Part Name Part No. No. 1 engine hanger 12281-37021 No. 2 engine hanger 12282-37011 Bolt 91552-81050

|

| 21. REMOVE ENGINE STAND |

Attach the engine to a sling device with the chain block.

Remove the engine from the engine stand.