Charging System Noise Occurs From V-Ribbed Belt Or Generator Assembly

INSPECTION PROCEDURE

CONFIRM PROBLEM SYMPTOM

CHECK V-RIBBED BELT FOR WEAR

CHECK GENERATOR PULLEY WITH CLUTCH FOR WEAR

CHECK FOR NOISE WHILE CLUTCH PULLEY IS OPERATING

INSPECT GENERATOR PULLEY WITH CLUTCH (UNIT INSPECTION)

CHECK FOR NOISE WHEN ROTOR IS TURNING FREELY

CHECK ENGAGEMENT OF GENERATOR PULLEY WITH CLUTCH

CHARGING SYSTEM - Noise Occurs from V-ribbed Belt or Generator Assembly |

INSPECTION PROCEDURE

| 1.CONFIRM PROBLEM SYMPTOM |

Confirm the problem symptom.

- Result:

Symptom

| Proceed to

|

Noise occurs from V-ribbed belt assembly

| A

|

Noise occurs from generator assembly

| B

|

| 2.CHECK V-RIBBED BELT FOR WEAR |

Check the V-ribbed belt for wear or damage.

- OK:

- The V-ribbed belt is not worn or damaged.

| | REPLACE OR ADJUST V-RIBBED BELT |

|

|

| 3.CHECK GENERATOR PULLEY WITH CLUTCH FOR WEAR |

Check the generator pulley with clutch grooves for wear or damage.

- OK:

- The generator pulley with clutch grooves are not worn or damaged.

| 4.CHECK FOR NOISE WHILE CLUTCH PULLEY IS OPERATING |

Start the engine and check the generator pulley with clutch for looseness.

- OK:

- The generator pulley with clutch is not loose.

| | TIGHTEN GENERATOR PULLEY WITH CLUTCH TO SPECIFIED TORQUE |

|

|

| 5.INSPECT GENERATOR PULLEY WITH CLUTCH (UNIT INSPECTION) |

Remove the generator assembly (COROLLA_ZRE142 RM00000219700JX.html).

Check the installation condition of the generator pulley cap.

- OK:

- The generator pulley cap is not loose or missing.

Check for forming of particles due to friction (for dry type pulley) or grease leaks (for wet type pulley).

- OK:

- There are no large amount of particles (for dry type pulley) or grease leaks (for wet type pulley).

Check the generator pulley with clutch for misalignment (interference with the generator assembly).

- OK:

- The generator pulley with clutch is not misaligned (no interference with the generator assembly).

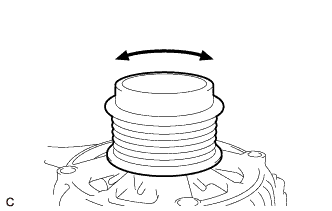

Turn the generator pulley with clutch clockwise and counterclockwise by hand and check for noise.

- OK:

- Noise does not occur when turned in both directions.

Turn the generator pulley with clutch clockwise and counterclockwise by hand and visually check for runout.

- OK:

- The generator pulley with clutch does not have runout.

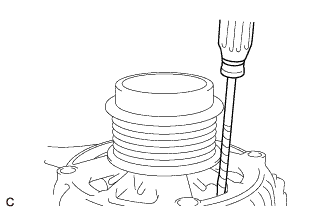

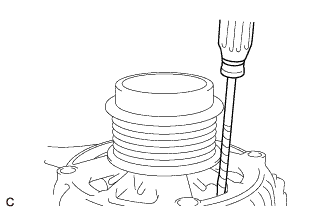

Hold the generator rotor assembly (fan) in the generator assembly with a screwdriver, and check that the generator pulley with clutch locks when turned clockwise and turns freely when turned counterclockwise.

- OK:

- The generator pulley with clutch locks when turned clockwise and turns freely when turned counterclockwise.

| OK |

|

|

|

| INSPECT PULLEY OTHER THAN GENERATOR ASSEMBLY PULLEY |

|

| 6.CHECK FOR NOISE WHEN ROTOR IS TURNING FREELY |

Perform a road test and check that noise does not occur when decelerating.

- OK:

- Noise does not occur.

Stop the engine and check that generator pulley with clutch noise does not occur as the engine stops.

- OK:

- Noise does not occur.

| 7.CHECK ENGAGEMENT OF GENERATOR PULLEY WITH CLUTCH |

Remove the generator assembly (COROLLA_ZRE142 RM00000219700JX.html).

Hold the generator rotor assembly (fan) in the generator assembly with a screwdriver, and check that the generator pulley with clutch locks when turned from counterclockwise (free turning direction) to clockwise (locking direction).

- OK:

- The generator pulley with clutch locks.