Crankshaft Position Sensor Installation

INSTALL CRANK POSITION SENSOR

INSTALL GENERATOR ASSEMBLY

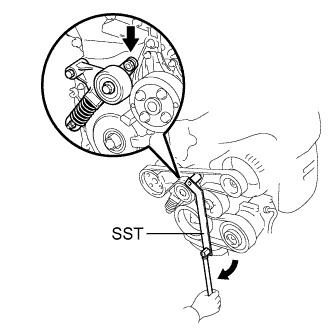

INSTALL V-RIBBED BELT

INSTALL ENGINE UNDER COVER RH

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

INSPECT FOR OIL LEAK

Crankshaft Position Sensor -- Installation |

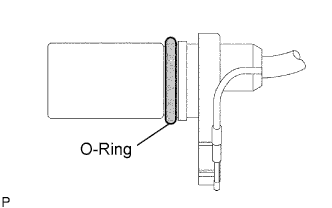

| 1. INSTALL CRANK POSITION SENSOR |

Apply a light coat of engine oil to the O-ring on the crank position sensor.

Install the crank position sensor with the bolt.

- Torque:

- 9.0 N*m{90 kgf*cm, 80 in.*lbf}

- NOTICE:

- Do not twist the O-ring.

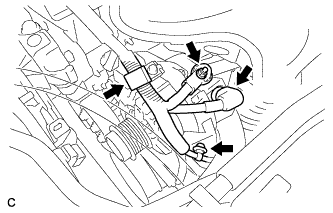

Install the wire harness and crank position sensor connector clamp.

Connect the crank position sensor connector.

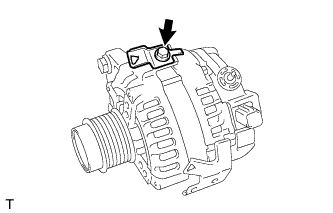

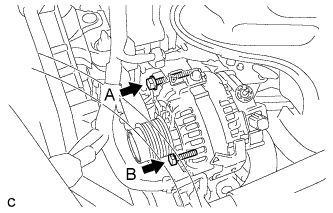

| 2. INSTALL GENERATOR ASSEMBLY |

Install the wire harness clamp bracket with the bolt.

Install the generator assembly with the 2 bolts.

- Torque:

- Bolt A:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

- Bolt B:

- 21 N*m{215 kgf*cm, 16 ft.*lbf}

Install the wire harness to terminal B with the nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

Attach the clamp and connect the generator connector to the generator.

Install the 2 wire harness clamps.

- HINT:

- The illustration shows the V-ribbed belt layout.

Using SST, slowly turn the V-ribbed belt tensioner clockwise and install the V-ribbed belt.

- SST

- 09216-42010(09216-04010)

- NOTICE:

- Make sure that SST and other tools are set to the tensioner securely.

- When compressing the V-ribbed belt tensioner, slowly turn the tensioner.

| 4. INSTALL ENGINE UNDER COVER RH |

| 5. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

Connect the cable to the negative battery terminal.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}