Water Pump -- Installation |

| 1. INSTALL WATER PUMP ASSEMBLY |

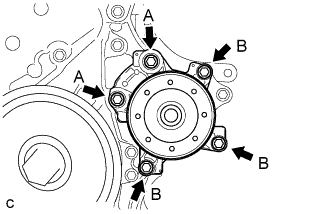

Align the protrusion of a new water pump gasket with the cutout in the timing chain cover and install the gasket to the groove of the timing chain cover.

- HINT:

- Be sure to clean the contact surfaces.

|

Install the water pump assembly to the timing chain cover with the 5 bolts.

- Torque:

- Bolt A:

- 26 N*m{260 kgf*cm, 19 ft.*lbf}

- Bolt B:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- Bolt Length:

Item Length Bolt A 35 mm (1.38 in.) Bolt B 25 mm (0.984 in.)

|

| 2. INSTALL GENERATOR ASSEMBLY |

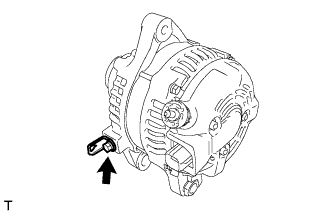

Install the wire harness clamp bracket with the bolt.

- Torque:

- 8.4 N*m{86 kgf*cm, 74 in.*lbf}

|

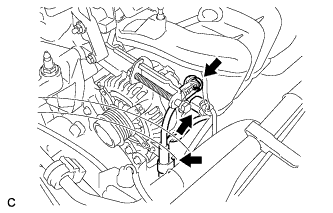

Temporarily install the generator assembly with the 2 bolts.

- Torque:

- Bolt A:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

- Bolt B:

- 19 N*m{190 kgf*cm, 14 ft.*lbf}

|

Install the connector and wire harness clamp.

|

Install the wire harness to terminal B with the nut and install the terminal cap.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

| 3. INSTALL V-RIBBED BELT |

Install the belt.

| 4. ADJUST V-RIBBED BELT |

Turn bolt C to adjust the tension of the V-ribbed belt.

|

Tighten bolts A and B.

- Torque:

- Bolt A:

- 19 N*m{190 kgf*cm, 14 ft.*lbf}

- Bolt B:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

- NOTICE:

- Confirm that bolt D is not loosened.

| 5. INSPECT V-RIBBED BELT |

Check the belt for wear, cracks or other signs of damage.

If any of the following defects is found, replace the V-ribbed belt.- The belt is cracked.

- The belt is worn out to the extent that the cords are exposed.

- The belt has chunks missing from the ribs.

- The belt is cracked.

|

Check that the belt fits properly in the ribbed grooves.

- HINT:

- Check with your hand to confirm that the belt has not slipped out of the groove on the bottom of the pulley. If it has slipped out, replace the V-ribbed belt. Install a new V-ribbed belt correctly.

|

Check the V belt deflection and tension.

- Deflection:

Item Specified Condition New belt 7.0 to 8.2 mm (0.276 to 0.323 in.) Used belt 7.6 to 10.0 mm (0.299 to 0.394 in.)

- Tension:

Item Specified Condition New belt 700 to 800 N (71 to 82 kg, 157 to 180 lb) Used belt 550 to 750 N (56 to 77 kg, 124 to 169 lb)

- HINT:

- When inspecting the V belt deflection, apply 98 N (10 kgf) tensile force to it.

- After installing a new belt, run the engine for approximately 5 minutes and then readjust the tension to (new belt) specifications.

- Check the V-ribbed belt deflection and tension at the specified point.

- V-ribbed belt tension and deflection should be checked after 2 revolutions of the engine.

- V-ribbed belt tension and deflection should be checked at TDC crank angle and cold condition.

- When adjusting a belt, adjust its deflection and tension to the intermediate values of the specification.

- When reinstalling a belt which has been used for over 5 minutes, adjust its deflection and tension to the used belt specification.

- When using a belt tension gauge, confirm its accuracy by using a master gauge first.

- If using a sonic tension meter:

- Weight:

- 15 g/rib*m

- Width:

- 6 ribs

- Span:

- 188 mm (7.40 in.) (w/ air Conditioning)

- 282 mm (11.1 in.) (w/o air Conditioning)

|

| 6. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

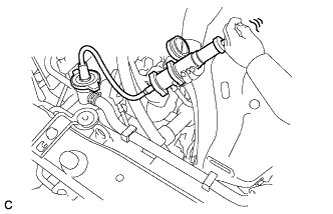

Connect the cable to the negative battery terminal.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 7. ADD ENGINE COOLANT |

Tighten the lower radiator drain cock plug.

Loosen the upper radiator drain cock plug.

Slowly fill the radiator with TOYOTA Super Long Life Coolant (SLLC).

- Standard Capacity:

Item Capacity Engine coolant 5.5 liters (5.8 US qts, 4.8 lmp. qts)

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology is a combination of low phosphates and organic acids).

- NOTICE:

- Never use water as a substitute for engine coolant.

Squeeze the inlet and outlet radiator hoses several times by hand, and then check the level of the coolant.

If the coolant level is low, add coolant.

Tighten the upper radiator drain cock plug.

Slowly pour coolant into the radiator reservoir tank until it reaches the FULL line.

Install the radiator cap sub-assembly and reservoir tank cap.

Start the engine and warm it up.

Bleed air from the cooling system.

- NOTICE:

- Before starting the engine, turn the A/C switch off.

- Adjust the air conditioning temperature setting to MAX (HOT).

- Adjust the air conditioning blower setting to LO.

Warm up the engine until the thermostat opens. While the thermostat is open, allow the coolant to circulate for several minutes.

- HINT:

- Thermostat opening timing can be determined by squeezing the inlet radiator hose, and sensing vibrations when the engine coolant starts to flow inside the hose.

- CAUTION:

- When squeezing the radiator hoses:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan.

Stop the engine, and wait until the engine coolant cools down.

Add engine coolant to the FULL line on the radiator reservoir.

| 8. INSPECT FOR COOLANT LEAK |

- CAUTION:

- To avoid the danger of being burned, do not remove the radiator cap sub-assembly while the engine and radiator assembly are still hot. Thermal expansion will cause hot engine coolant and steam to blow out from the radiator assembly.

Fill the radiator assembly with engine coolant, then attach a radiator cap tester.

|

Pump it to 118 kPa (1.2 kgf/cm2, 17.0 psi), then check that the pressure does not drop.

If the pressure drops, check the hoses, radiator assembly and water pump assembly for leakage. If there are no signs or traces of external engine coolant leakage, check the heater core, cylinder block and head.

| 9. INSTALL ENGINE UNDER COVER RH |

| 10. INSTALL NO. 2 CYLINDER HEAD COVER |

Engage the 4 clips to install the No. 2 cylinder head cover.

- NOTICE:

- Be sure to engage the clips securely.

- Do not apply excessive force or do not hit the cover to engage the clips. This may cause the cover to break.

|