DESCRIPTION

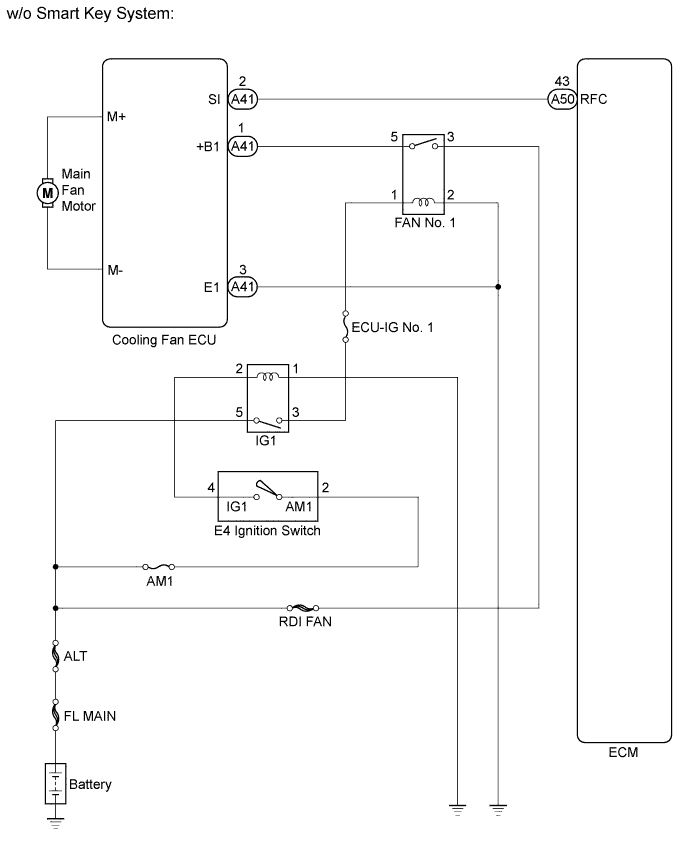

WIRING DIAGRAM

INSPECTION PROCEDURE

PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL COOLING FAN)

INSPECT COOLING FAN ECU

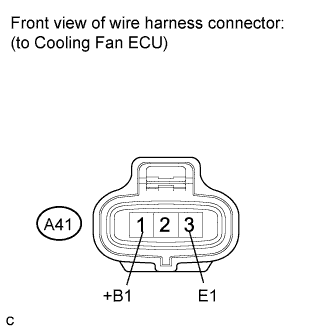

CHECK HARNESS AND CONNECTOR (ECM - COOLING FAN ECU)

INSPECT COOLING FAN MOTOR

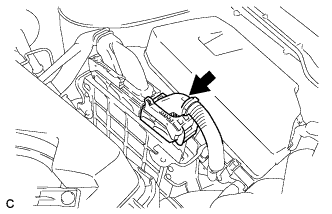

CHECK COOLING FAN ECU (POWER SOURCE)

CHECK HARNESS AND CONNECTOR (COOLING FAN ECU - BODY GROUND)

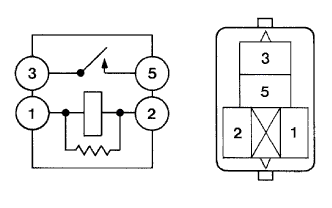

INSPECT FAN NO. 1 RELAY

INSPECT FUSIBLE LINK BLOCK (RDI FAN FUSE)

INSPECT FUSE (ECU-IG NO. 1 FUSE)

CHECK HARNESS AND CONNECTOR (COOLING FAN ECU - FAN NO. 1 RELAY)

CHECK HARNESS AND CONNECTOR (FAN NO. 1 RELAY - BODY GROUND)

CHECK HARNESS AND CONNECTOR (FAN NO. 1 RELAY - ECU-IG NO. 1 FUSE)

CHECK HARNESS AND CONNECTOR (FAN NO. 1 RELAY - RDI FAN FUSE)

CHECK HARNESS AND CONNECTOR (ECM - COOLING FAN ECU)

COOLING FAN SYSTEM - Cooling Fan Circuit |

DESCRIPTION

The ECM calculates an appropriate cooling fan speed based on the engine coolant temperature, air conditioning switch condition, refrigerant pressure, engine speed, and vehicle speed and sends the signals to the cooling fan ECU to regulate the cooling fan. The cooling fan ECU controls the cooling fan speed based on the duty ratio signal sent from the ECM. By basing its control on the operating conditions, the ECM can control the fan speed optimally using the cooling fan ECU, achieving both high cooling performance and quietness. The cooling fan speed is determined based on the engine coolant temperature, air conditioner operating conditions, engine speed, and vehicle speed.

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL COOLING FAN) |

Connect the Techstream to the DLC3.

Turn the ignition switch to ON.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Electric Cooling Fan.

Check the operation of the cooling fan using the Techstream.

- OK:

Tester Operation

| Fan Operation

|

ON

| Cooling fan operates

|

OFF

| Cooling fan stopped

|

- Result:

Result

| Proceed to

|

OK

| A

|

NG (Cooling fan does not operate)

| B

|

NG (Cooling fan does not stop)

| C

|

| 2.INSPECT COOLING FAN ECU |

Disconnect the ECM connector.

Turn the ignition switch to ON.

Check the operation of the cooling fan.

- OK:

- The cooling fan operates.

Reconnect the ECM connector.

| 3.CHECK HARNESS AND CONNECTOR (ECM - COOLING FAN ECU) |

Disconnect the cooling fan ECU connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

Tester Connection

| Condition

| Specified Condition

|

A50-43 (RFC) - A41-2 (SI)

| Always

| Below 1 Ω

|

- Standard Resistance (Check for Short):

Tester Connection

| Condition

| Specified Condition

|

A50-43 (RFC) or A41-2 (SI) - Body ground

| Always

| 10 kΩ or higher

|

Reconnect the ECM connector.

Reconnect the cooling fan ECU connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (ECM - COOLING FAN ECU) |

|

|

| 4.INSPECT COOLING FAN MOTOR |

Disconnect the cooling fan ECU connector.

Connect a battery positive (+) lead to terminal 2 of the cooling fan motor connector, and connect a battery negative (-) lead to terminal 1 of the cooling fan motor connector.

Check the cooling fan motor.

- OK:

- The cooling fan operates.

Reconnect the cooling fan ECU connector.

| 5.CHECK COOLING FAN ECU (POWER SOURCE) |

Disconnect the cooling fan ECU connector.

Turn the ignition switch to ON.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

A41-1 (+B1) - A41-3 (E1)

| Ignition switch ON

| 11 to 14 V

|

Reconnect the cooling fan ECU connector.

| 6.CHECK HARNESS AND CONNECTOR (COOLING FAN ECU - BODY GROUND) |

Disconnect the cooling fan ECU connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

A41-3 (E1) - Body ground

| Always

| Below 1 Ω

|

Reconnect the cooling fan ECU connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (COOLING FAN ECU - BODY GROUND) |

|

|

| 7.INSPECT FAN NO. 1 RELAY |

Remove the FAN No. 1 relay from the engine room relay block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

3 - 5

| Normal

| 10 kΩ or higher

|

3 - 5

| Apply battery voltage between terminals 1 and 2

| Below 1 Ω

|

Reinstall the FAN No. 1 relay.

| 8.INSPECT FUSIBLE LINK BLOCK (RDI FAN FUSE) |

Check the RDI FAN fuse.

| | REPLACE FUSIBLE LINK BLOCK |

|

|

| 9.INSPECT FUSE (ECU-IG NO. 1 FUSE) |

Remove the ECU-IG No. 1 fuse from the instrument panel junction block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

ECU-IG No. 1 fuse

| Always

| Below 1 Ω

|

Reinstall the ECU-IG No. 1 fuse.

| | REPLACE FUSE (ECU-IG NO. 1 FUSE) |

|

|

| 10.CHECK HARNESS AND CONNECTOR (COOLING FAN ECU - FAN NO. 1 RELAY) |

Disconnect the cooling fan ECU connector.

Remove the FAN No. 1 relay from the engine room relay block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

Tester Connection

| Condition

| Specified Condition

|

A41-1 (+B1) - 5 (FAN No.1 relay)

| Always

| Below 1 Ω

|

- Standard Resistance (Check for Short):

Tester Connection

| Condition

| Specified Condition

|

A41-1 (+B1) or 5 (FAN No.1 relay) - Body ground

| Always

| 10 kΩ or higher

|

Reconnect the cooling fan ECU connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (COOLING FAN ECU - FAN NO. 1 RELAY) |

|

|

| 11.CHECK HARNESS AND CONNECTOR (FAN NO. 1 RELAY - BODY GROUND) |

Remove the FAN No. 1 relay from the engine room relay block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

2 (FAN No.1 relay) - Body ground

| Always

| Below 1 Ω

|

Reinstall the FAN No. 1 relay.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (FAN NO. 1 RELAY - BODY GROUND) |

|

|

| 12.CHECK HARNESS AND CONNECTOR (FAN NO. 1 RELAY - ECU-IG NO. 1 FUSE) |

Remove the ECU-IG No. 1 fuse from the instrument panel junction block.

Remove the FAN No. 1 relay from the engine room relay block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

Tester Connection

| Condition

| Specified Condition

|

2 (ECU-IG No. 1 fuse) - 1 (FAN No.1 relay)

| Always

| Below 1 Ω

|

- Standard Resistance (Check for Short):

Tester Connection

| Condition

| Specified Condition

|

2 (ECU-IG No. 1 fuse) or 1 (FAN No.1 relay) - Body ground

| Always

| 10 kΩ or higher

|

Reinstall the ECU-IG No. 1 fuse.

Reinstall the FAN No. 1 relay.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (FAN NO. 1 RELAY - ECU-IG NO. 1 FUSE) |

|

|

| 13.CHECK HARNESS AND CONNECTOR (FAN NO. 1 RELAY - RDI FAN FUSE) |

Remove the fusible link block assembly from the engine room relay block.

Disconnect the fusible link block connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

Tester Connection

| Condition

| Specified Condition

|

3 (FAN No. 1 relay) - 1C-2 (Fusible link block)

| Always

| Below 1 Ω

|

- Standard Resistance (Check for Short):

Tester Connection

| Condition

| Specified Condition

|

3 (FAN No. 1 relay) or 1C-2 (Fusible link block) - Body ground

| Always

| 10 kΩ or higher

|

Reconnect the fusible link block connector.

Reinstall the fusible link block assembly.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (FAN NO. 1 RELAY - RDI FAN FUSE) |

|

|

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS OR CONNECTOR (BATTERY - RDI FAN FUSE) |

|

| 14.CHECK HARNESS AND CONNECTOR (ECM - COOLING FAN ECU) |

Disconnect the cooling fan ECU connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

A50-43 (RFC) - A41-2 (SI)

| Always

| Below 1 Ω

|

Reconnect the ECM connector.

Reconnect the cooling fan ECU connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (ECM - COOLING FAN ECU) |

|

|