Cylinder Block Disassembly

INSPECT CONNECTING ROD THRUST CLEARANCE

INSPECT CONNECTING ROD OIL CLEARANCE

REMOVE PISTON SUB-ASSEMBLY WITH CONNECTING ROD

REMOVE CONNECTING ROD BEARING

REMOVE PISTON RING SET

REMOVE PISTON PIN HOLE SNAP RING

REMOVE PISTON

INSPECT CRANKSHAFT THRUST CLEARANCE

REMOVE CRANKSHAFT

REMOVE UPPER CRANKSHAFT THRUST WASHER

REMOVE CRANKSHAFT BEARING

REMOVE NO. 2 CRANKSHAFT BEARING

REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY

REMOVE STUD BOLT

REMOVE RING PIN

REMOVE STRAIGHT PIN

Cylinder Block -- Disassembly |

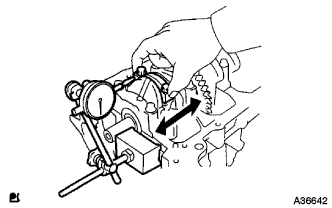

| 1. INSPECT CONNECTING ROD THRUST CLEARANCE |

Install the connecting rod cap (COROLLA_ZRE142 RM00000224E012X.html).

Using a dial indicator, measure the thrust clearance while moving the connecting rod back and forth.

- Standard thrust clearance:

- 0.160 to 0.362 mm (0.00630 to 0.0143 in.)

- Maximum thrust clearance:

- 0.362 mm (0.0143 in.)

If the thrust clearance is greater than the maximum, replace the connecting rod assemblies as necessary. If necessary, replace the crankshaft.

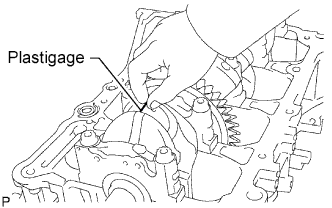

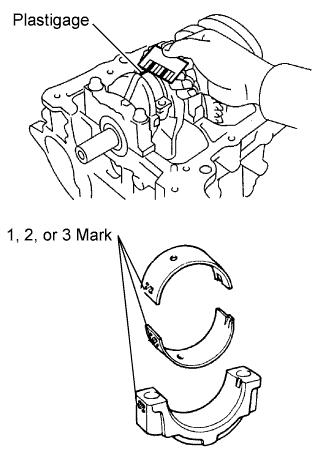

| 2. INSPECT CONNECTING ROD OIL CLEARANCE |

Clean the crank pin and bearing.

Check the crank pin and bearing for pitting and scratches.

Lay a strip of Plastigage on the crank pin.

Check that the front mark of the connecting rod cap is facing forward.

Install the connecting rod cap (COROLLA_ZRE142 RM00000224E012X.html).

- NOTICE:

- Do not turn the crankshaft.

Remove the 2 bolts and connecting rod cap (COROLLA_ZRE142 RM00000224D012X.html).

|

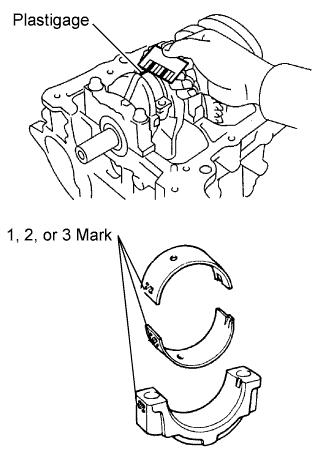

Measure the Plastigage at its widest point.

- Standard oil clearance:

- 0.024 to 0.048 mm (0.000945 to 0.00189 in.)

- Maximum oil clearance:

- 0.063 mm (0.00248 in.)

- NOTICE:

- Completely remove the Plastigage after the measurement.

If the oil clearance is greater than the maximum, replace the connecting rod bearings. If necessary, inspect the crankshaft.

- HINT:

- If replacing a bearing, replace it with one that has the same number as its respective connecting rod cap. Each bearing's standard thickness is indicated by a 1, 2, or 3 mark on its surface.

- Standard Connecting Rod Large End Bore Diameter:

Mark

| Specified Condition

|

Mark 1

| 51.000 to 51.007 mm (2.0079 to 2.0082 in.)

|

Mark 2

| 51.008 to 51.013 mm (2.0082 to 2.0084 in.)

|

Mark 3

| 51.014 to 51.020 mm (2.0084 to 2.0087 in.)

|

- Standard Connecting Rod Bearing Thickness:

Mark

| Specified Condition

|

Mark 1

| 1.485 to 1.488 mm (0.0585 to 0.0586 in.)

|

Mark 2

| 1.489 to 1.491 mm (0.0586 to 0.0587 in.)

|

Mark 3

| 1.492 to 1.494 mm (0.0587 to 0.0588 in.)

|

- Standard crankshaft pin diameter:

- 47.990 to 48.000 (1.8894 to 1.8898 in.)

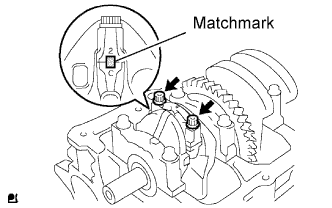

| 3. REMOVE PISTON SUB-ASSEMBLY WITH CONNECTING ROD |

Check that the matchmarks on the connecting rod and cap are aligned to ensure the correct reassembly.

- HINT:

- The matchmarks on the connecting rods and caps are provided for ensuring the correct reassembly.

Using a 12 mm socket wrench, uniformly loosen and remove the 2 bolts.

Using the 2 removed connecting rod cap bolts, remove the connecting rod cap and lower bearing by wiggling the connecting rod cap right and left.

- HINT:

- Keep the lower bearing inserted in the connecting rod cap.

Push the piston, connecting rod assembly and upper bearing through the top of the cylinder block.

- HINT:

- Keep the bearing, connecting rod and cap together.

- Arrange the piston and connecting rod assemblies in the correct order.

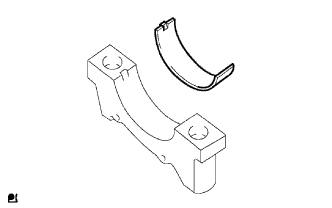

| 4. REMOVE CONNECTING ROD BEARING |

Remove the connecting rod bearings.

- HINT:

- Arrange the removed parts in the correct order.

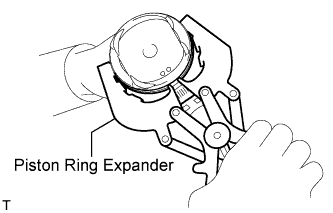

| 5. REMOVE PISTON RING SET |

Using a piston ring expander, remove the 2 compression rings.

Remove the oil ring rail and oil ring expander by hand.

- HINT:

- Arrange the removed parts in the correct order.

| 6. REMOVE PISTON PIN HOLE SNAP RING |

Using a screwdriver, pry out the 2 snap rings.

Gradually heat the piston to between 80 and 90°C (176 and 194°F).

Using a plastic hammer and brass bar, lightly tap out the piston pin and remove the connecting rod.

- HINT:

- The piston and pin are a matched set.

- Arrange the pistons, pin, rings, connecting rods and bearings in the correct order.

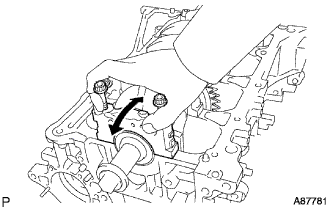

| 8. INSPECT CRANKSHAFT THRUST CLEARANCE |

Install the main bearing cap (COROLLA_ZRE142 RM00000224E012X.html).

Using a dial indicator, measure the thrust clearance while prying the crankshaft back and forth with a screwdriver.

- Standard thrust clearance:

- 0.04 to 0.24 mm (0.00157 to 0.00945 in.)

- Maximum thrust clearance:

- 0.30 mm (0.0118 in.)

If the thrust clearance is greater than the maximum, replace the thrust washers as a set.

- HINT:

- The thrust washer thickness is 1.93 to 1.98 mm (0.0760 to 0.0780 in.).

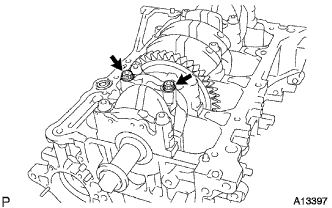

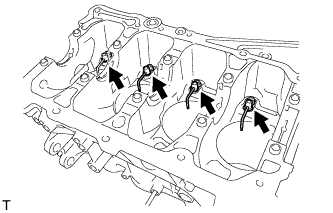

Uniformly loosen and remove the 10 main bearing cap bolts in the sequence shown in the illustration.

Use 2 removed main bearing cap bolts to remove the 5 main bearing caps and 5 lower bearings.

- NOTICE:

- Insert the bolts into one of the caps. Ease the cap out by gently pulling up and applying force toward the front and back side of the cylinder block, as shown in the illustration. Take care not to damage the contact surfaces of the cap and cylinder block.

- HINT:

- Keep the lower bearing and main bearing cap.

- Arrange the main bearing caps in the correct order.

Lift out the crankshaft.

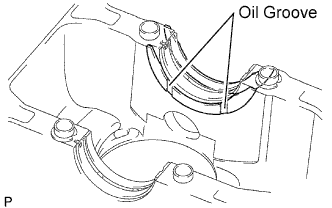

| 10. REMOVE UPPER CRANKSHAFT THRUST WASHER |

Remove the upper thrust washers from the cylinder block.

| 11. REMOVE CRANKSHAFT BEARING |

Remove the 5 crankshaft bearings from the cylinder block.

- HINT:

- Arrange the removed parts in the correct order.

| 12. REMOVE NO. 2 CRANKSHAFT BEARING |

Remove the 5 No. 2 crankshaft bearings from the 5 main bearing caps.

- HINT:

- Arrange the removed parts in the correct order.

| 13. REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY |

Using a 5 mm hexagon wrench, remove the bolts and oil nozzles.