Dtc B1423 Pressure Sensor Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT)

CHECK HARNESS AND CONNECTOR (GROUND CIRCUIT)

INSPECT A/C PRESSURE SENSOR (SENSOR SIGNAL CIRCUIT)

INSPECT A/C PRESSURE SENSOR (SENSOR SIGNAL CIRCUIT)

CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - A/C PRESSURE SENSOR)

CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - A/C PRESSURE SENSOR)

CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - A/C PRESSURE SENSOR)

CHECK FOR A/C SYSTEM LEAK

CHARGE REFRIGERANT

RECHECK DTC

INSPECT A/C PRESSURE SENSOR

REPAIR A/C SYSTEM LEAK

INSPECT COOLING FAN SYSTEM

CHARGE REFRIGERANT

RECHECK DTC

REPLACE EXPANSION VALVE

CHARGE REFRIGERANT

RECHECK DTC

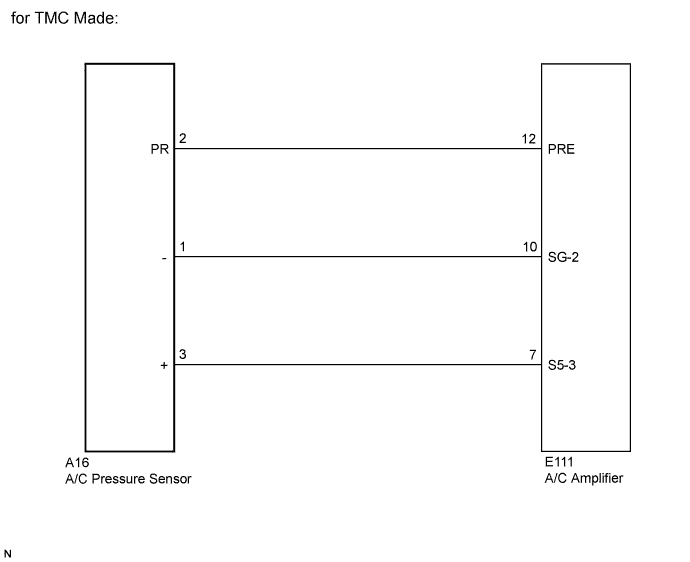

DTC B1423 Pressure Sensor Circuit |

DESCRIPTION

This DTC is output when refrigerant pressure on the high pressure side is extremely low (0.19 MPa (2.0 kgf/cm2, 28 psi) or less) or extremely high (3.14 MPa (32.0 kgf/cm2, 455 psi) or more). The A/C pressure sensor, installed on the high pressure line to detect refrigerant pressure, outputs a refrigerant pressure signal to the A/C amplifier. The A/C amplifier converts this signal to a pressure value according to the sensor characteristics to control the compressor.DTC No.

| DTC Detection Condition

| Trouble Area

|

B1423

| - Open or short in A/C pressure sensor circuit

- Refrigerant pressure on the high pressure line is extremely low (0.19 MPa (2.0 kgf/cm2, 28 psi) or less) or extremely high (3.14 MPa (32.0 kgf/cm2, 455 psi) or more).

| - A/C Pressure sensor

- Harness or connector between A/C pressure sensor and A/C amplifier

- A/C amplifier

- Expansion valve (blocked, stuck)

- Condenser (blocked, deterioration of cooling capacity due to dirt)

- Cooler dryer (moisture in the refrigerant cycle cannot be absorbed)

- Cooling fan system (condenser cannot be cooled down)

- A/C system (leaks, blocked)

|

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

Disconnect the connector from the A/C pressure sensor.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

A16-3 (+) - Body ground

| Ignition switch ON

| 4.75 to 5.25 V

|

Text in Illustration*a

| Front view of wire harness connector

(to A/C Pressure Sensor)

|

| 2.CHECK HARNESS AND CONNECTOR (GROUND CIRCUIT) |

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

A16-1 (-) - Body ground

| Always

| Below 1 Ω

|

Text in Illustration*a

| Front view of wire harness connector

(to A/C Pressure Sensor)

|

| 3.INSPECT A/C PRESSURE SENSOR (SENSOR SIGNAL CIRCUIT) |

Reconnect the connector to the A/C pressure sensor.

Remove the A/C amplifier with the connectors still connected.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Condition

| Specified Condition

|

E62-6 (PRE) - Body ground*1

| Ignition switch ON

(A/C: OFF)

| 0.7 to 4.8 V

|

E111-12 (PRE) - Body ground*2

| Ignition switch ON

(A/C: OFF)

| 0.7 to 4.8 V

|

- *1: except TMC Made 2AZ-FE

- *2: for TMC Made and except TMC Made 2ZR-FE

- HINT:

- If the measured voltage is not within the normal range, there may be a malfunction in the A/C amplifier, A/C pressure sensor, or wire harness. It is also possible that the amount of refrigerant may not be appropriate.

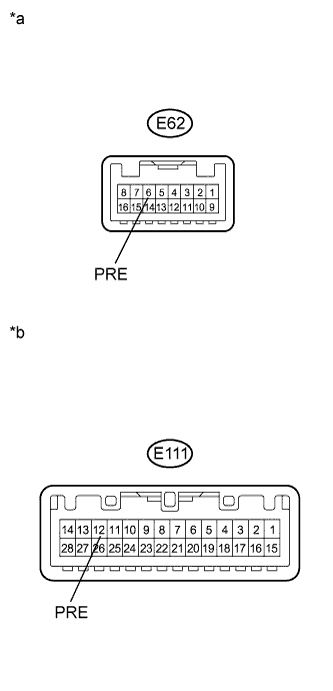

Text in Illustration*a

| Component with wire harness connected

(A/C Amplifier (except TMC Made 2AZ-FE))

|

*b

| Component with wire harness connected

(A/C Amplifier (for TMC Made and except TMC Made 2ZR-FE))

|

| 4.INSPECT A/C PRESSURE SENSOR (SENSOR SIGNAL CIRCUIT) |

Measure the voltage when the following conditions are satisfied.

Item

| Condition

|

Vehicle Doors

| Fully open

|

Temperature Setting

| MAX COLD

|

Blower Speed

| HI

|

A/C Switch

| ON

|

R/F Switch

| RECIRCULATION

|

Interior Temperature

| 25 to 35°C (77 to 95°F)

|

Engine Speed

| 2000 rpm

|

- NOTICE:

- If refrigerant pressure on the high pressure line becomes extremely high during the inspection (if the voltage exceeds 4.8 V), the fail-safe function stops compressor operation. Therefore, measure the voltage before the fail-safe function operates.

- It is necessary to measure the voltage over a period of time (approximately 10 minutes) because the problem symptom may recur after a while.

- HINT:

- When the outside air temperature is low (below -1.5°C (29.3°F)), the compressor stops due to operation of the ambient temperature sensor and the evaporator temperature sensor to prevent the evaporator from freezing. In this case, perform the inspection in a warm indoor environment.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Condition

| Specified Condition

|

E62-6 (PRE) - Body ground*1

| Ignition switch ON

(A/C: ON)

| 0.7 to 4.8 V

|

E111-12 (PRE) - Body ground*2

| Ignition switch ON

(A/C: ON)

| 0.7 to 4.8 V

|

- *1: except TMC Made 2AZ-FE

- *2: for TMC Made and except TMC Made 2ZR-FE

- Result:

Result

| Proceed to

|

OK (When troubleshooting according to DTC)

| A

|

OK (When troubleshooting according to Problem Symptoms Table)

| B

|

NG

| C

|

Text in Illustration*a

| Component with wire harness connected

(A/C Amplifier (except TMC Made 2AZ-FE))

|

*b

| Component with wire harness connected

(A/C Amplifier (for TMC Made and except TMC Made 2ZR-FE))

|

| 5.CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - A/C PRESSURE SENSOR) |

Disconnect the connector from the A/C amplifier.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

A16-3 (+) - E62-1 (S5-3)*1

| Always

| Below 1 Ω

|

E62-1 (S5-3) - Body ground*1

| Always

| 10 kΩ or higher

|

A16-3 (+) - E111-7 (S5-3)*2

| Always

| Below 1 Ω

|

E111-7 (S5-3) - Body ground*2

| Always

| 10 kΩ or higher

|

- *1: except TMC Made 2AZ-FE

- *2: for TMC Made and except TMC Made 2ZR-FE

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 6.CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - A/C PRESSURE SENSOR) |

Disconnect the connector from the A/C amplifier.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

A16-1 (-) - E62-4 (SG-2)*1

| Always

| Below 1 Ω

|

E62-4 (SG-2) - Body ground*1

| Always

| 10 kΩ or higher

|

A16-1 (-) - E111-10 (SG-2)*2

| Always

| Below 1 Ω

|

E111-10 (SG-2) - Body ground*2

| Always

| 10 kΩ or higher

|

- *1: except TMC Made 2AZ-FE

- *2: for TMC Made and except TMC Made 2ZR-FE

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 7.CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - A/C PRESSURE SENSOR) |

Disconnect the connector from the A/C amplifier.

Disconnect the connector from the A/C pressure sensor.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

A16-2 (PR) - E62-6 (PRE)*1

| Always

| Below 1 Ω

|

E62-6 (PRE) - Body ground*1

| Always

| 10 kΩ or higher

|

A16-2 (PR) - E111-12 (PRE)*2

| Always

| Below 1 Ω

|

E111-12 (PRE) - Body ground*2

| Always

| 10 kΩ or higher

|

- *1: except TMC Made 2AZ-FE

- *2: for TMC Made and except TMC Made 2ZR-FE

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 8.CHECK FOR A/C SYSTEM LEAK |

Install the manifold gauge set.

Recover the refrigerant from the A/C system using a refrigerant recovery unit.

Evacuate the A/C system and check that vacuum can be maintained.

- OK:

- Vacuum can be maintained in the A/C system.

- HINT:

- If vacuum cannot be maintained in the A/C system, there may be a refrigerant leak. In this case, it is necessary to repair or replace the leaking part of the A/C system.

Add an appropriate amount of refrigerant (COROLLA_ZRE142 RM00000114604ZX_01_0002.html).

Recheck for DTCs when the following conditions are satisfied.

Item

| Condition

|

Vehicle Doors

| Fully open

|

Temperature Setting

| MAX COLD

|

Blower Speed

| HI

|

A/C Switch

| ON

|

R/F Switch

| RECIRCULATION

|

Interior Temperature

| 25 to 35°C (77 to 95°F)

|

Engine Speed

| 2000 rpm

|

- NOTICE:

- If refrigerant pressure on the high pressure line is excessive, this DTC will be set. Therefore, it is necessary to measure the voltage over a period of time (approximately 10 minutes) because this DTC may be set after the A/C has been operating for a while.

- HINT:

- When the outside air temperature is low (below -1.5°C (29.3°F)), the compressor stops due to signals from the ambient temperature sensor and the evaporator temperature sensor to prevent the evaporator from freezing. In this case, perform the inspection in a warm indoor environment.

- Result:

Result

| Proceed to

|

DTC B1423 is output

| A

|

DTC B1423 is not output

| B

|

- NOTICE:

- If the DTC was set due to an insufficient or excessive amount of refrigerant, the problem may have been solved after performing the previous step. However, the root cause of insufficient refrigerant may be refrigerant leaks. The root cause of excessive refrigerant may be adding refrigerant when the level was insufficient. Therefore, identify and repair any refrigerant leaks as necessary.

| 11.INSPECT A/C PRESSURE SENSOR |

Install the manifold gauge set.

Disconnect the connector from the A/C pressure sensor.

Connect the three 1.5 V dry cell batteries' positive (+) lead to terminal 3, and the negative (-) lead to terminal 1.

Connect the voltmeter's positive (+) lead to terminal 2, and the negative (-) lead to terminal 1.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Condition

| Specified Condition

|

A16-2 (PR) - A16-1 (-)

| Refrigerant pressure:

0.39 to 3.187 MPa (57 to 463 psi)

| 1.0 to 4.8 V

|

Text in Illustration*a

| Component without harness connected

(A/C Pressure Sensor)

|

*b

| Voltage (V)

|

*c

| Refrigerant Pressure (MPa (psi))

|

| 12.REPAIR A/C SYSTEM LEAK |

Identify the area where refrigerant leaks from (COROLLA_ZRE142 RM00000114604ZX_01_0004.html).

Repair the identified area of the A/C system.

Evacuate the A/C system.

| 13.INSPECT COOLING FAN SYSTEM |

Check that the cooling fan operates normally.

- HINT:

- Cooling Fan Circuit (COROLLA_ZRE142 RM000002YZE03NX.html for 2AZ-FE).

- Cooling Fan Circuit (COROLLA_ZRE142 RM000002WE9079X.html for 2ZR-FE).

| | REPAIR COOLING FAN SYSTEM |

|

|

Use a refrigerant recovery unit to recover refrigerant.

Evacuate the A/C system.

Add an appropriate amount of refrigerant (COROLLA_ZRE142 RM00000114604ZX_01_0002.html).

- HINT:

- If refrigerant is added and the system has not been properly evacuated (insufficient vacuum time), moisture in the air remaining in the system will freeze in the expansion valve, blocking the flow on the high pressure side. Therefore, recover the refrigerant and properly evacuate the system. Add an appropriate amount of refrigerant, and check for DTCs.

Recheck for DTCs when the following conditions are satisfied.

Item

| Condition

|

Vehicle Doors

| Fully open

|

Temperature Setting

| MAX COLD

|

Blower Speed

| HI

|

A/C Switch

| ON

|

R/F Switch

| RECIRCULATION

|

Interior Temperature

| 25 to 35°C (77 to 95°F)

|

Engine Speed

| 2000 rpm

|

- NOTICE:

- If refrigerant pressure on the high pressure line is excessive, this DTC will be set. Therefore, it is necessary to measure the voltage over a period of time (approximately 10 minutes) because DTC may be set after the A/C has been operating for a while.

- HINT:

- When the outside air temperature is low (below -1.5°C (29.3°F)), the compressor stops due to signals from the ambient temperature sensor and the evaporator temperature sensor to prevent the evaporator from freezing. In this case, perform the inspection in a warm indoor environment.

- If refrigerant is added and the system has not been properly evacuated (insufficient vacuum time), moisture in the air remaining in the system will freeze in the expansion valve, blocking the flow on the high pressure side. Therefore, recover the refrigerant and properly evacuate the system. Add an appropriate amount of refrigerant, and check for DTCs. If the DTC is not output, it indicates that the cooler dryer in the condenser is not able to absorb moisture in the refrigerant. In this case, to complete the repair, it is necessary to replace the cooler dryer.

- Result:

Result

| Proceed to

|

DTC B1423 is output

| A

|

DTC B1423 is not output

| B

|

| 16.REPLACE EXPANSION VALVE |

Replace the expansion valve with a new one (COROLLA_ZRE142 RM000001HLX05GX.html).

- HINT:

- Replace the expansion valve with a normal one because the expansion valve is either stuck or clogged.

Add an appropriate amount of refrigerant (COROLLA_ZRE142 RM00000114604ZX_01_0002.html).

Recheck for DTCs when the following conditions are satisfied.

Item

| Condition

|

Vehicle Doors

| Fully open

|

Temperature Setting

| MAX COLD

|

Blower Speed

| HI

|

A/C Switch

| ON

|

R/F Switch

| RECIRCULATION

|

Interior Temperature

| 25 to 35°C (77 to 95°F)

|

Engine Speed

| 2000 rpm

|

- NOTICE:

- If refrigerant pressure on the high pressure line is excessive, this DTC will be set. Therefore, it is necessary to measure the voltage over a period of time (approximately 10 minutes) because this DTC may be set after the A/C has been operating for a while.

- HINT:

- When the outside air temperature is low (below -1.5°C (29.3°F)), the compressor stops due to operation of the ambient temperature sensor and the evaporator temperature sensor to prevent the evaporator from freezing. In this case, perform the inspection in a warm indoor environment.

- If refrigerant pressure is not normal after replacing the expansion valve with a new one, the condenser or pipes may be clogged with dirt, dust or other contaminants. In this case, clean or replace the condenser or pipes.

- Result:

Result

| Proceed to

|

DTC B1423 is not output

| A

|

DTC B1423 is output

| B

|