Differential Case Reassembly

INSTALL DIFFERENTIAL SIDE GEAR

INSTALL FRONT NO. 1 DIFFERENTIAL PINION SHAFT

INSPECT DIFFERENTIAL SIDE GEAR BACKLASH

INSTALL FRONT DIFFERENTIAL PINION SHAFT STRAIGHT PIN

INSTALL FRONT DIFFERENTIAL CASE REAR TAPERED ROLLER BEARING

INSTALL FRONT DIFFERENTIAL CASE FRONT TAPERED ROLLER BEARING

ADJUST DIFFERENTIAL SIDE BEARING PRELOAD

INSTALL FRONT DIFFERENTIAL RING GEAR

INSTALL TRANSAXLE CASE OIL SEAL

INSTALL FRONT TRANSAXLE CASE OIL SEAL

Differential Case -- Reassembly |

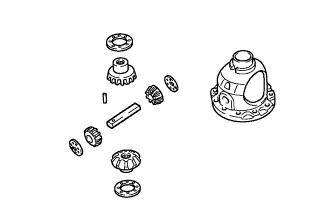

| 1. INSTALL DIFFERENTIAL SIDE GEAR |

Coat the 2 front differential side gears, 2 side gear thrust washers, 2 front differential pinions and 2 pinion thrust washers with ATF and install them to the differential case.

| 2. INSTALL FRONT NO. 1 DIFFERENTIAL PINION SHAFT |

Coat the front No. 1 differential pinion shaft with ATF, and install it to the differential case.

| 3. INSPECT DIFFERENTIAL SIDE GEAR BACKLASH |

Hold the differential case in a vise between aluminum plates.

- NOTICE:

- Do not overtighten the vise.

Place a dial indicator on the tip of the side gear tooth at a right angle.

Hold the pinion gear in the differential case and measure the backlash of the side gear.

- Standard backlash:

- 0 to 0.15 mm (0 to 0.0059 in.)

Thrust washer thicknessThickness

| Thickness

|

1.50 mm (0.0591 in.)

| 1.75 mm (0.0689 in.)

|

1.55 mm (0.0610 in.)

| 1.80 mm (0.0709 in.)

|

1.60 mm (0.0630 in.)

| 1.85 mm (0.07283 in.)

|

1.65 mm (0.0650 in.)

| 1.90 mm (0.07480 in.)

|

1.70 mm (0.0669 in.)

| -

|

If the backlash is greater than the standard range, select another side gear thrust washer.

| 4. INSTALL FRONT DIFFERENTIAL PINION SHAFT STRAIGHT PIN |

Using a pin punch (3 mm) and hammer, install the pinion shaft straight pin.

- NOTICE:

- Align the holes, and install the pinion shaft straight pin.

Using a chisel and hammer, stake the differential case.

- NOTICE:

- Stake the differential case after adjusting the backlash.

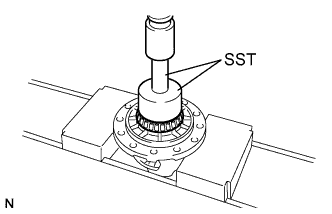

| 5. INSTALL FRONT DIFFERENTIAL CASE REAR TAPERED ROLLER BEARING |

Using SST and a press, install the front differential case rear tapered roller bearing to the differential case.

- SST

- 09726-36010

09950-70010(09951-07100)

- NOTICE:

- Do not damage the bearing cage during bearing inner race installation.

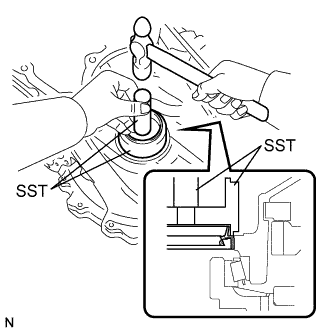

Using SST and a hammer, install the front differential case rear tapered roller bearing outer race to the transaxle case.

- SST

- 09950-60020(09951-00890)

09950-70010(09951-07150)

- NOTICE:

- Ensure that there is no clearance between the bearing and transaxle case.

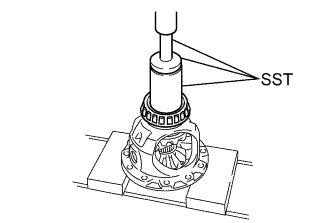

| 6. INSTALL FRONT DIFFERENTIAL CASE FRONT TAPERED ROLLER BEARING |

Using SST and a press, install the front differential case front tapered roller bearing to the differential case.

- SST

- 09710-30012(09710-04081)

09950-60010(09951-00480)

09950-70010(09951-07100)

- NOTICE:

- Do not damage the bearing cage during bearing inner race installation.

Install the shim to the transaxle housing.

Using SST and a hammer, install the front differential case front tapered roller bearing outer race to the transaxle housing.

- SST

- 09950-60020(09951-00890)

09950-70010(09951-07150)

- NOTICE:

- Ensure that there is no clearance between the bearing and transaxle housing.

| 7. ADJUST DIFFERENTIAL SIDE BEARING PRELOAD |

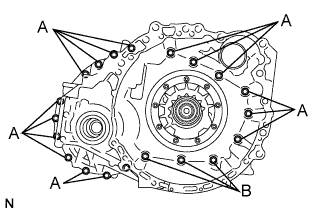

Install the differential assembly to the transaxle case.

Clean the contact surfaces of the transaxle case and transaxle housing.

Install the transaxle housing to the transaxle case with the 20 bolts.

- Torque:

- Bolt A:

- 31 N*m{316 kgf*cm, 23 ft.*lbf}

- Bolt B:

- 23 N*m{234 kgf*cm, 17 ft.*lbf}

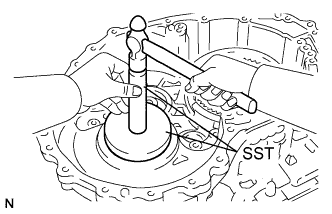

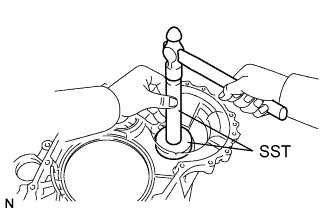

Using SST, turn the differential assembly right and left 2 or 3 times to settle the bearing.

- SST

- 09564-33010

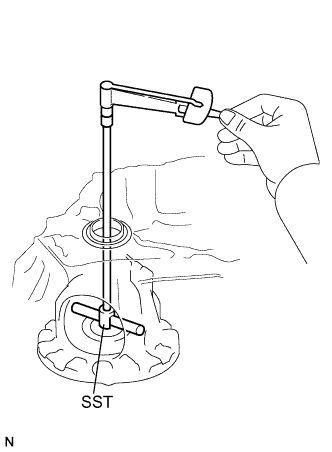

Using SST and a torque wrench, measure the turning torque of the differential side bearing while rotating SST at 10 rpm.

- SST

- 09564-33010

- Turning torque:

- 1.05 to 1.93 N*m (10.70 to 19.67 kgf*cm, 9.29 to 17.08 in.*lbf)

If the turning torque is not within the specified range, refer to the table below to select a shim so that the turning torque is within the specified range.

Shim thickness: mm (in.)Thickness

| Thickness

| Thickness

| Thickness

|

2.000 (0.0787)

| 2.225 (0.0876)

| 2.450 (0.0965)

| 2.675 (0.1054)

|

2.025 (0.0797)

| 2.250 (0.0886)

| 2.475 (0.0974)

| 2.700 (0.1063)

|

2.050 (0.0807)

| 2.275 (0.0896)

| 2.500 (0.0984)

| 2.725 (0.1073)

|

2.075 (0.0817)

| 2.300 (0.0906)

| 2.525 (0.0994)

| 2.750 (0.1083)

|

2.100 (0.0827)

| 2.325 (0.0915)

| 2.550 (0.1004)

| 2.775 (0.1093)

|

2.125 (0.0837)

| 2.350 (0.0925)

| 2.575 (0.1014)

| 2.800 (0.1102)

|

2.150 (0.0847)

| 2.375 (0.0935)

| 2.600 (0.1024)

| 2.825 (0.1112)

|

2.175 (0.0856)

| 2.400 (0.0945)

| 2.625 (0.1034)

| 2.850 (0.1122)

|

2.200 (0.0866)

| 2.425 (0.0955)

| 2.650 (0.1043)

| 2.875 (0.1132)

|

Remove the 20 bolts and the transaxle housing from the transaxle case.

Remove the differential assembly from the transaxle case.

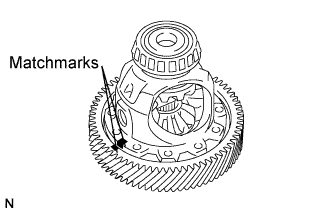

| 8. INSTALL FRONT DIFFERENTIAL RING GEAR |

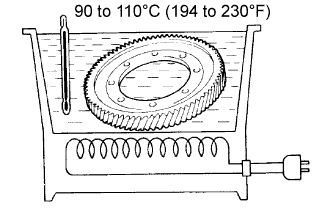

Using ATF and a heater, heat the front differential ring gear to 90 to 110°C (194.0 to 230.0°F).

- NOTICE:

- Do not heat the ring gear to more than 110°C (230.0°F).

Clean the contact surface of the front differential case.

Align the matchmarks, and install the front differential ring gear case quickly.

- NOTICE:

- Do not install the bolts while the ring gear is hot.

Tighten the 12 bolts.

- Torque:

- 120 N*m{1,223 kgf*cm, 88 ft.*lbf}

- NOTICE:

- Tighten the bolts a little at a time in diagonal order.

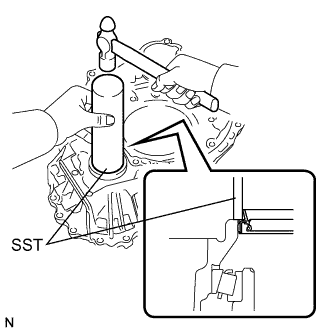

| 9. INSTALL TRANSAXLE CASE OIL SEAL |

Coat the lip of a new oil seal with MP grease.

Using SST and a hammer, install the oil seal.

- SST

- 09316-10010

09950-70010(09951-07100)

- Oil seal drive in depth:

- -0.5 to 0.5 mm (-0.0197 to 0.0197 in.)

| 10. INSTALL FRONT TRANSAXLE CASE OIL SEAL |

Coat the lip of a new oil seal with MP grease.

Using SST and a hammer, install the oil seal.

- SST

- 09308-14010

- Oil seal drive in depth:

- -0.5 to 0.5 mm (-0.0197 to 0.0197 in.)