Engine Assembly -- Installation |

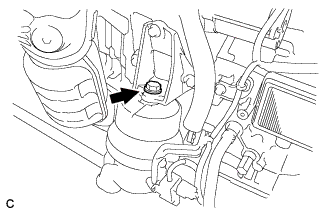

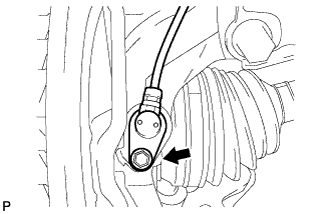

| 1. INSTALL ENGINE COOLANT TEMPERATURE SENSOR |

Using a 19 mm deep socket wrench, install the engine coolant temperature sensor and a new gasket.

- Torque:

- 20 N*m{200 kgf*cm, 14 ft.*lbf}

|

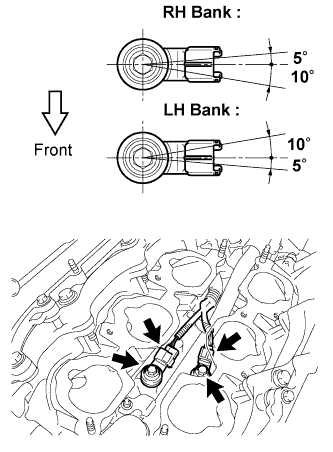

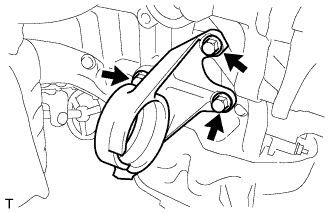

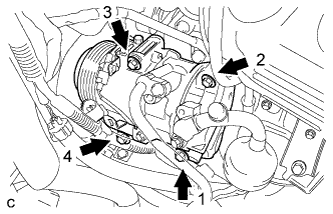

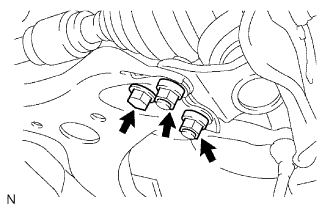

| 2. INSTALL KNOCK CONTROL SENSOR |

Install the 2 knock control sensors with the 2 bolts as shown in the illustration.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

|

Connect the 2 knock control sensor connectors.

| 3. INSTALL ENGINE OIL PRESSURE SWITCH ASSEMBLY |

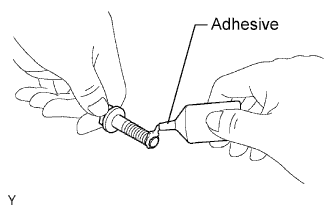

Clean the threads of the oil pressure switch. Apply adhesive to 2 or 3 threads of the oil pressure switch.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent.

|

Using a 24 mm deep socket wrench, install the oil pressure switch.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- NOTICE:

- Do not start the engine within 1 hour after installation to prevent oil leaks.

|

| 4. INSTALL NO. 1 VACUUM SWITCHING VALVE ASSEMBLY |

Install the bolt and No. 1 vacuum switching valve.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

| 5. INSTALL RADIO SETTING CONDENSER |

Install the 2 bolts and 2 radio setting condensers.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

| 6. INSTALL NO. 1 ENGINE MOUNTING BRACKET FRONT LH |

Install the No. 1 engine mounting bracket front LH with the 6 bolts.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

|

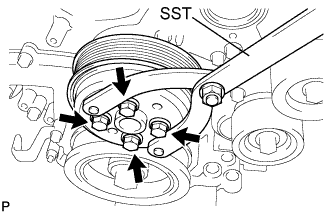

| 7. INSTALL WATER PUMP PULLEY |

Temporarily install the water pump pulley with the 4 bolts.

|

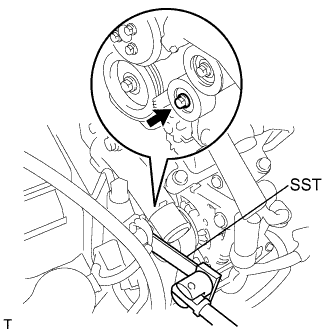

Using SST, hold the water pump pulley.

- SST

- 09960-10010(09962-01000,09963-00700)

Tighten the 4 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

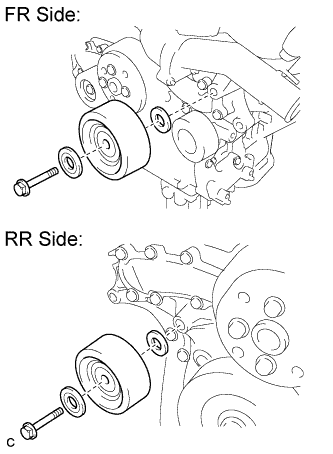

| 8. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY |

Install the No. 2 idler pulley sub-assembly and 2 plates with the bolt.

- Torque:

- 54 N*m{550 kgf*cm, 40 ft.*lbf}

- HINT:

- Plate diameter:

- Idler pulley cover plate: 33.6 mm (1.32 in.)

- No. 2 idler pulley cover plate: 37.8 mm (1.49 in.)

|

| 9. INSTALL NO. 2 TIMING GEAR COVER |

Install the No. 2 timing gear cover with the 2 bolts.

- Torque:

- 6.0 N*m{61 kgf*cm, 53 in.*lbf}

|

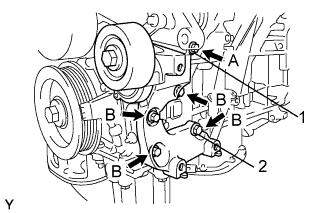

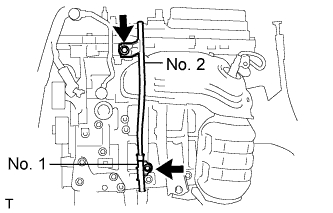

| 10. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY |

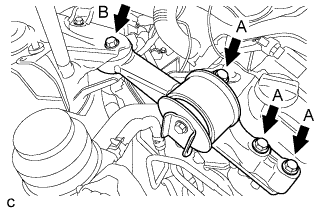

Temporarily install the V-ribbed belt tensioner with the 5 bolts.

- HINT:

- Each bolt length is as follows:

- A: 70 mm (2.76 in.)

- B: 33 mm (1.30 in.)

|

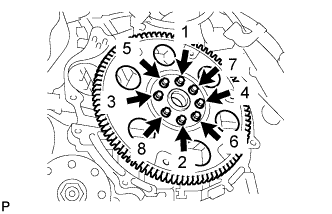

Install the V-ribbed belt tensioner by tightening the bolt 1 and bolt 2 in the order shown in the illustration.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

Tighten the other bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

| 11. INSTALL DRIVE SHAFT BEARING BRACKET |

Install the drive shaft bearing bracket with the 3 bolts.

- Torque:

- 64 N*m{650 kgf*cm, 47 ft.*lbf}

|

| 12. INSTALL ENGINE MOUNTING BRACKET RH |

Install the engine mounting bracket RH with the 3 bolts.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

|

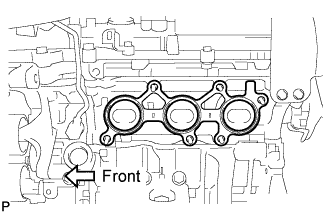

| 13. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH |

Install a new gasket as shown in the illustration.

|

Install the exhaust manifold sub-assembly LH with the 6 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

| 14. INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR |

Install the No. 2 insulator with the 3 bolts.

- Torque:

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

|

| 15. INSTALL NO. 2 MANIFOLD STAY |

Install the No. 2 manifold stay with the bolt and nut.

- Torque:

- 34 N*m{347 kgf*cm, 25 ft.*lbf}

|

| 16. INSTALL OIL LEVEL GAUGE GUIDE SUB-ASSEMBLY |

Install 2 new O-rings to the oil level gauge guide.

|

Apply a light coat of engine oil to the O-rings.

Push in the oil level gauge guide end into the guide hole.

Install the oil level gauge guide No. 1 with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Install the oil level gauge guide No. 2 with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Install the oil level gauge.

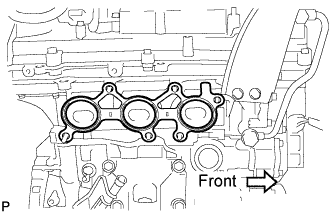

| 17. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH |

Install a new gasket as shown in the illustration.

|

Install the exhaust manifold sub-assembly RH with the 6 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

| 18. INSTALL INTAKE MANIFOLD |

- NOTICE:

- Do not apply oil to the bolts used to install the components listed below:

| Components | ||

| Intake Manifold and Cylinder Head Sub-assembly RH | ||

| Intake Manifold and Cylinder Head Sub-assembly LH |

Set a new gasket on each cylinder head.

- NOTICE:

- Align the port holes of the gasket and cylinder head.

- Make sure that the gasket is installed in the correct direction.

|

Set the intake manifold on the cylinder heads.

Install and tighten the 6 bolts and 4 nuts uniformly in several steps.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 19. INSTALL NO. 2 ENGINE MOUNTING STAY RH |

Install the No. 2 mounting stay RH with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 20. INSTALL IGNITION COIL ASSEMBLY |

Install the 6 ignition coil assemblies with the 6 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

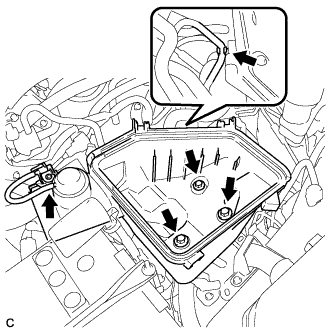

| 21. INSTALL INTAKE AIR SURGE TANK ASSEMBLY |

- NOTICE:

- Do not apply oil to the bolts used to install the components listed below:

| Components | ||

| Surge Tank and Intake Manifold | ||

| No. 1 Surge Tank Stay and Cylinder Head Cover | ||

| No. 1 Surge Tank Stay and Surge Tank | ||

| Throttle Body Bracket and Cylinder Head Cover | ||

| Throttle Body Bracket and Surge Tank |

Install a new gasket to the intake air surge tank.

Using a 5 mm hexagon socket wrench, install the 4 bolts and 2 nuts.

- Torque:

- Bolt:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

- Nut:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

|

Install the throttle body bracket, No. 1 surge tank stay and 4 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

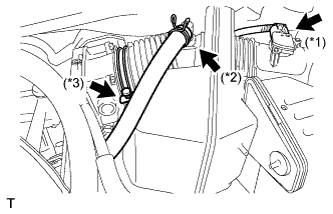

Connect the connector.

|

Install the vacuum hose clamp with the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

|

Connect the No. 1 ventilation hose.

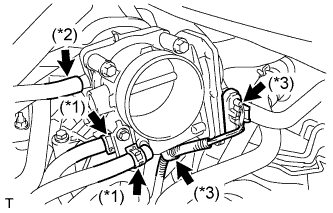

Install the clamp and connect the throttle body assembly connector (*3).

|

Connect the vapor feed hose (*2).

Connect the 2 water by-pass hoses to the throttle body assembly (*1).

| 22. REMOVE ENGINE STAND |

| 23. INSTALL DRIVE PLATE AND RING GEAR SUB-ASSEMBLY |

Using SST, hold the crankshaft.

- SST

- 09213-70011(09213-70020)

09330-00021

|

Apply adhesive to 2 or 3 threads of the mounting bolt end.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent.

Install the front spacer, drive plate and rear spacer on the crankshaft.

Install and tighten the 8 mounting bolts uniformly in several steps.

- Torque:

- 83 N*m{850 kgf*cm, 61 ft.*lbf}

|

| 24. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY |

- HINT:

| 25. INSTALL STARTER ASSEMBLY |

Install the starter assembly with the 2 bolts.

- Torque:

- 37 N*m{380 kgf*cm, 28 ft.*lbf}

|

Connect the wire harness to terminal 30 and install the nut. Then, attach the terminal cap.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

Connect the terminal 50 connector to the starter assembly.

| 26. INSTALL ENGINE WIRE |

| 27. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH |

Coat the spline of the inboard joint shaft assembly with ATF.

|

Align the shaft splines and install the drive shaft assembly LH with a brass bar and hammer.

- NOTICE:

- Set the shaft snap ring with the opening side facing down.

- Be careful not to damage the drive shaft dust cover, boot, and oil seal.

- Move the drive shaft assembly while keeping it level.

| 28. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH |

Coat the spline of the inboard joint shaft assembly with ATF.

|

Install the front drive shaft the assembly RH.

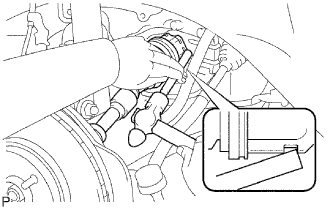

Using a screwdriver, install a new bearing bracket hole snap ring.

- NOTICE:

- Do not damage the boot and oil seal.

- Move the drive shaft assembly while keeping it level.

Install a new bolt.

- Torque:

- 32 N*m{330 kgf*cm, 24 ft.*lbf}

| 29. INSTALL FRONT FRAME ASSEMBLY |

Install the engine mounting insulators RH and LH with the 2 nuts.

- Torque:

- 95 N*m{969 kgf*cm, 70 ft.*lbf}

|

Install the engine mounting insulator FR with the bolt.

- Torque:

- 87 N*m{887 kgf*cm, 64 ft.*lbf}

|

Connect the connector and clamp.

|

Connect the 2 clamps.

|

| 30. INSTALL VANE PUMP ASSEMBLY |

Install the vane pump with the 2 bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

|

Install the pressure feed tube clamp bolt.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

Connect the power steering oil pressure switch connector.

| 31. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE |

Set the engine assembly with transaxle on the engine lifter.

|

Install the engine assembly to the vehicle.

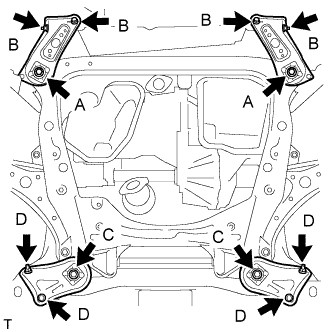

Install the frame side rail plates RH and LH with the 4 bolts and 2 nuts.

- Torque:

- A:

- 85 N*m{867 kgf*cm, 63 ft.*lbf}

- B:

- 32 N*m{329 kgf*cm, 24 ft.*lbf}

Install the front suspension member brace rear RH and LH with the 4 bolts and 2 nuts.

- Torque:

- C:

- 85 N*m{867 kgf*cm, 63 ft.*lbf}

- D:

- 32 N*m{329 kgf*cm, 24 ft.*lbf}

| 32. INSTALL COOLER COMPRESSOR ASSEMBLY |

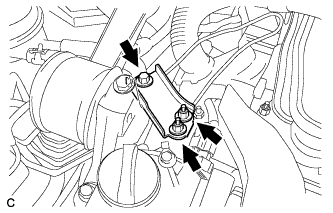

Temporarily install the cooler compressor with the 4 bolts.

|

Install the compressor with the 4 bolts by tightening the bolts in the order shown in the illustration.

- Torque:

- 25 N*m{250 kgf*cm, 18 ft.*lbf}

Install the 2 connector clamps.

| 33. INSTALL GENERATOR ASSEMBLY |

Install the bracket with the bolt.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

|

Install the wire harness clamp stay with the bolt.

- Torque:

- 8.4 N*m{86 kgf*cm, 74 in.*lbf}

|

Connect the wire harness clamp.

|

Install the generator assembly to the cylinder block with the bolt.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Install the 2 bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

|

Connect the generator connector to the generator assembly.

|

Install the generator wire with the nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

Install the terminal cap.

Connect the 2 wire harness clamps.

Connect the magnetic clutch connector to the compressor and magnetic clutch.

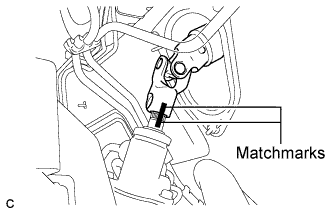

| 34. INSTALL STEERING SLIDING YOKE |

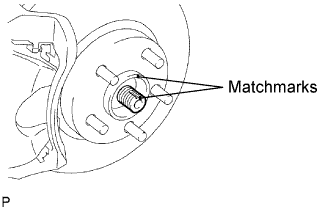

Align the matchmarks on the steering sliding yoke and the steering link assembly.

|

Install the bolt.

- Torque:

- 35 N*m{360 kgf*cm, 26 ft.*lbf}

|

| 35. INSTALL DRIVE PLATE AND TORQUE CONVERTER CLUTCH SETTING BOLT |

Apply a few drops of adhesive to 2 threads on the tip of the 6 torque converter clutch mounting bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

|

Install the 6 torque converter clutch mounting bolts.

- Torque:

- 41 N*m{418 kgf*cm, 30 ft.*lbf}

- NOTICE:

- First install the black colored bolt, and then the silver colored 5 bolts.

|

| 36. INSTALL NO. 1 EXHAUST PIPE SUPPORT BRACKET |

Install the No. 1 exhaust pipe support bracket with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 37. INSTALL FRONT AXLE ASSEMBLY LH |

Align the matchmarks and install the front drive shaft assembly to the front axle hub sub-assembly.

- NOTICE:

- Be careful not to damage the drive shaft boot and speed sensor rotor.

|

| 38. INSTALL FRONT AXLE ASSEMBLY RH |

- HINT:

- Use the same procedure described for the LH side.

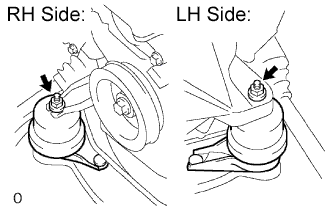

| 39. INSTALL FRONT SUSPENSION LOWER NO. 1 ARM LH |

Install the lower ball joint to the front suspension lower No. 1 arm with the bolt and 2 nuts.

- Torque:

- 75 N*m{765 kgf*cm, 55 ft.*lbf}

|

| 40. INSTALL FRONT SUSPENSION LOWER NO. 1 ARM RH |

- HINT:

- Use the same procedure described for the LH side.

| 41. INSTALL TIE ROD ASSEMBLY LH |

Install the tie rod end sub-assembly to the steering knuckle with the nut.

- Torque:

- 49 N*m{500 kgf*cm, 36 ft.*lbf}

Install a new cotter pin.

- NOTICE:

- If the holes for the cotter pin are not aligned, tighten the nut up to 60° further.

| 42. INSTALL TIE ROD ASSEMBLY RH |

- HINT:

- Use the same procedure described for the LH side.

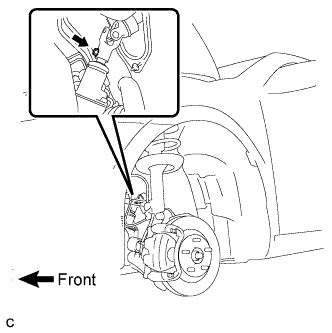

| 43. INSTALL FRONT SPEED SENSOR LH |

Install the front speed sensor to the steering knuckle with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

- NOTICE:

- Prevent foreign matter from adhering to the speed sensor.

- Be careful not to damage the speed sensor.

|

Install the flexible hose and the speed sensor to the shock absorber with the bolt and set the sensor clip on the knuckle.

- Torque:

- 19 N*m{192 kgf*cm, 14 ft.*lbf}

- NOTICE:

- Be careful not to damage the speed sensor.

- Prevent foreign matter from adhering to the speed sensor.

- Do not twist the sensor wire when installing the speed sensor.

|

| 44. INSTALL FRONT SPEED SENSOR RH |

- HINT:

- Use the same procedure described for the LH side.

| 45. INSTALL FRONT STABILIZER LINK ASSEMBLY LH |

Install the stabilizer link assembly with the nut.

- Torque:

- 74 N*m{755 kgf*cm, 55 ft.*lbf}

- HINT:

- If the ball joint turns together with the nut, use a hexagon wrench (6 mm) to hold the stud.

|

| 46. INSTALL FRONT STABILIZER LINK ASSEMBLY RH |

- HINT:

- Use the same procedure described for the LH side.

| 47. INSTALL FRONT AXLE HUB NUT LH |

Clean the threaded parts on the drive shaft and front axle hub nut using a non-residue solvent.

- NOTICE:

- Be sure to perform this work for a new drive shaft. Keep the threaded parts free of oil and foreign objects.

Using a socket wrench (30 mm), install a new axle hub nut.

- Torque:

- 294 N*m{3,000 kgf*cm, 217 ft.*lbf}

|

Using a chisel and hammer, stake the front axle hub nut.

| 48. INSTALL FRONT AXLE HUB NUT RH |

- HINT:

- Use the same procedure described for the LH side.

| 49. INSTALL EXHAUST PIPE ASSEMBLY FRONT |

Install 2 new gaskets to the exhaust front pipe.

Install the exhaust front pipe to the exhaust manifolds with the 4 nuts.

- Torque:

- 62 N*m{632 kgf*cm, 46 ft.*lbf}

| 50. INSTALL EXHAUST PIPE NO. 1 SUPPORT BRACKET |

Install the front support brackets with the 2 nuts.

- Torque:

- 33 N*m{337 kgf*cm, 24 ft.*lbf}

- NOTICE:

- Be sure to install the support brackets in the correct direction.

|

| 51. CONNECT NO. 1 OIL RESERVOIR TO PUMP HOSE |

Connect the No. 1 oil reservoir to pump hose.

|

| 52. CONNECT RETURN TUBE SUB-ASSEMBLY |

Connect the return tube sub-assembly.

|

| 53. CONNECT FUEL TUBE SUB-ASSEMBLY |

Push in the fuel tube connector to the fuel pipe until the connector makes a "click" sound.

- NOTICE:

- Check for damage or contamination on the connected part of the pipe.

- Check if the pipe and the connector are securely connected by trying to pull them apart.

|

Install the No. 1 fuel pipe clamp.

|

| 54. CONNECT TRANSMISSION CONTROL CABLE ASSEMBLY |

Install the clip and nut to connect the cable to the transaxle.

- Torque:

- 13 N*m{130 kgf*cm, 9 ft.*lbf}

|

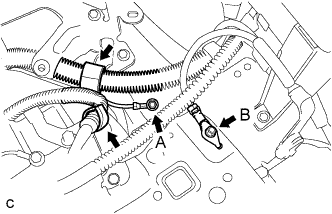

| 55. CONNECT ENGINE WIRE |

Install the bolt and clamp to the bracket.

- Torque:

- 8.4 N*m{85 kgf*cm, 74 in.*lbf}

|

Install the 2 bolts and 2 clamps to the body.

- Torque:

- Bolt A:

- 12 N*m{123 kgf*cm, 9 ft.*lbf}

- Bolt B:

- 8.4 N*m{85 kgf*cm, 74 in.*lbf}

|

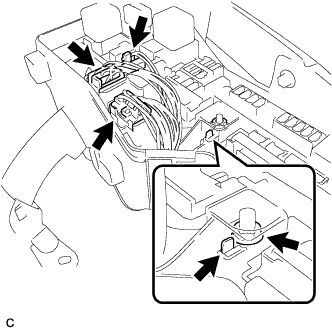

Connect the connectors to the engine room junction block. Then, install it with the nut and 3 connectors.

- Torque:

- 8.4 N*m{85 kgf*cm, 74 in.*lbf}

|

| 56. INSTALL RELAY BLOCK COVER UPPER |

| 57. INSTALL ECM |

- HINT:

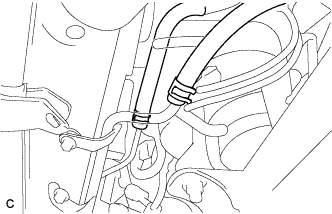

| 58. CONNECT HEATER WATER HOSE INLET |

Connect the heater inlet water hose.

|

| 59. CONNECT HEATER WATER HOSE OUTLET |

Connect the heater outlet water hose.

| 60. CONNECT NO. 1 OIL COOLER INLET HOSE |

Install the clamp and connect the oil cooler inlet hose.

|

| 61. CONNECT NO. 1 OIL COOLER OUTLET HOSE |

Install the clamp and connect the oil cooler outlet hose.

| 62. INSTALL RADIATOR HOSE INLET |

Install the clamp and connect the radiator hose inlet.

|

| 63. INSTALL RADIATOR HOSE OUTLET |

Install the clamp and connect the radiator hose outlet.

|

| 64. CONNECT CHECK VALVE TO BRAKE BOOSTER HOSE |

Install the clamp and connect the check valve to brake booster hose.

|

| 65. CONNECT NO. 1 FUEL VAPOR FEED HOSE |

Install the clamp and connect the No. 1 fuel vapor feed hose.

|

| 66. INSTALL ENGINE MOVING CONTROL ROD SUB-ASSEMBLY |

Temporarily install the engine moving control rod with the 4 bolts.

|

First install the bolts labeled A in the illustration, and then the remaining bolt B.

- Torque:

- 38 N*m{388 kgf*cm, 28 ft.*lbf}

| 67. INSTALL NO. 2 ENGINE MOUNTING STAY RH |

Temporarily install the No. 2 engine mounting stay RH with the bolt.

- Torque:

- 38 N*m{388 kgf*cm, 28 ft.*lbf}

|

Tighten the 2 nuts.

- Torque:

- 23 N*m{235 kgf*cm, 17 ft.*lbf}

| 68. INSTALL INTAKE AIR RESONATOR SUB-ASSEMBLY |

Install the intake air resonator with the bolt and clip.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

|

| 69. INSTALL BATTERY |

Install the battery and battery tray.

|

Install the battery clamp with the bolt and nut.

- Torque:

- Bolt:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

- Nut:

- 3.5 N*m{36 kgf*cm, 31 in.*lbf}

| 70. INSTALL NO. 1 AIR CLEANER INLET |

Install the No. 1 air cleaner inlet with the bolt.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

|

| 71. INSTALL AIR CLEANER CASE SUB-ASSEMBLY |

Install the air cleaner case with the 3 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

|

Connect the vacuum hose and hose clamp.

| 72. INSTALL AIR CLEANER CAP SUB-ASSEMBLY |

Install the air cleaner cap sub-assembly, and connect the 3 bands.

|

Connect the mass air flow meter connector (*1).

|

Connect the No. 2 ventilation hose (*2).

Connect the hose band (*3).

Connect the 3 vacuum hoses.

|

| 73. INSTALL AIR CLEANER INLET ASSEMBLY |

Install the air cleaner inlet with the clamp and 2 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

|

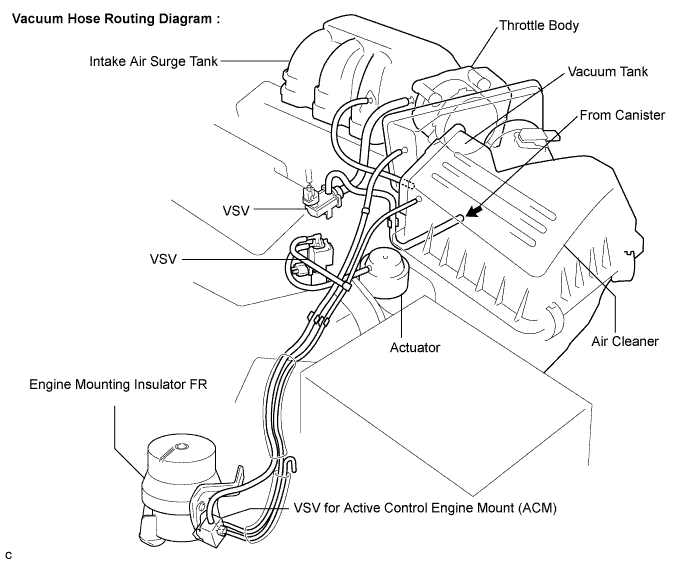

| 74. CONNECT VACUUM HOSES |

| 75. INSTALL V-RIBBED BELT |

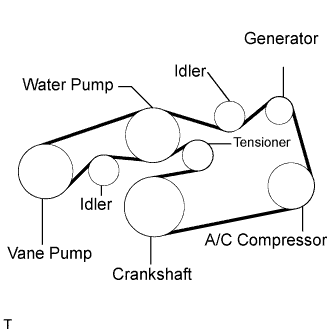

Install the V-ribbed belt.

|

Using SST, turn the belt tensioner counterclockwise and remove the bar.

- SST

- 09249-63010

If it is difficult to install the V-ribbed belt, perform the following procedure:

Put the V-ribbed belt on every pulley except the tensioner pulley as shown in the illustration.

While releasing the belt tension by turning the belt tensioner counterclockwise, put the V-ribbed belt on the tensioner pulley.

- NOTICE:

- Put the backside of the V-ribbed belt on the tensioner pulley and idler pulley.

- Check that the V-ribbed belt is properly set to each pulley.

After installing the V-ribbed belt, check that it fits properly in the ribbed grooves. Confirm that the belt has not slipped out of the grooves on the bottom of the crank pulley by hand.

|

| 76. INSTALL COWL TOP PANEL OUTER SUB-ASSEMBLY |

Install the cowl top panel outer sub-assembly with the 4 bolts and 4 nuts.

- Torque:

- Bolt:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

- Nut:

- 85 N*m{867 kgf*cm, 63 ft.*lbf}

|

| 77. INSTALL WINDSHIELD WIPER LINK ASSEMBLY |

- HINT:

| 78. INSTALL FRONT WHEELS |

- Torque:

- 103 N*m{1,050 kgf*cm, 76 ft.*lbf}

| 79. ADD ENGINE OIL |

| 80. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- Torque:

- 6.9 N*m{70 kgf*cm, 61 in.*lbf}

| 81. ADD ENGINE COOLANT |

Close the radiator drain cock plug and 2 cylinder block drain cock plugs.

- Torque:

- 13 N*m{130 kgf*cm, 9 ft.*lbf} for cylinder block drain cock plug

Slowly fill the radiator with TOYOTA Super Long Life Coolant (SLLC).

- Specified capacity:

- 9.0 liters (9.5 US qts, 7.9 lmp. qts)

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

- Contact your TOYOTA dealer for further details.

Slowly pour coolant into the radiator reservoir tank until it reaches the FULL line.

Press the inlet and outlet radiator hoses several times by hand, and then check the level of the coolant.

If the coolant level is low, add coolant.

Install the radiator cap sub-assembly and reservoir tank cap.

Start the engine, and warm it up.

- HINT:

- Adjust the air conditioner set temperature to MAX (HOT).

Stop the engine, and wait until the engine coolant cools down.

Add engine coolant to the FULL line on the radiator reservoir.

| 82. ADD AUTOMATIC TRANSAXLE FLUID |

- HINT:

| 83. ADD POWER STEERING FLUID |

| 84. BLEED POWER STEERING FLUID |

Check the fluid level (CAMRY_ACV40 RM000001A0S01SX_01_0006.html).

Jack up the front of the vehicle and support it with stands.

Turn the steering wheel.

With the engine stopped, turn the steering wheel slowly from lock to lock several times.

Lower the vehicle.

Start the engine.

Run the engine at idle for a few minutes.

Turn the steering wheel.

With the engine idling, turn the steering wheel left or right to the full lock position and keep it in that position for 2 to 3 seconds, then turn the steering wheel to the opposite full lock position and keep it there for 2 to 3 seconds.

Repeat this procedure several times.

Stop the engine.

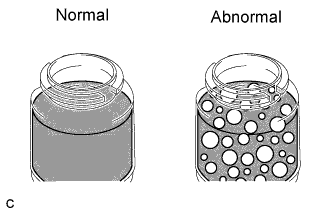

Check for foaming or emulsification.

- HINT:

- If the system has to be bled twice because of forming or emulsification, be sure to check for fluid leaks in the system.

|

Check the fluid level (CAMRY_ACV40 RM000001A0S01SX_01_0006.html).

| 85. CHECK FOR FUEL LEAKS |

Check fuel pump operation.

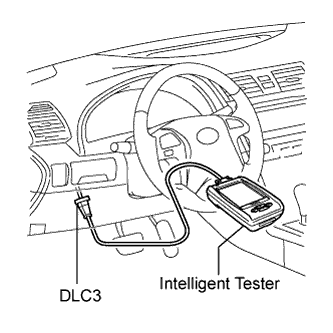

Connect the intelligent tester to the DLC3.

Turn the ignition switch to the ON position and push the intelligent tester main switch on.

- NOTICE:

- Do not start the engine.

Select the following menus: Powertrain / Engine / Active Test / Control the Fuel Pump /Speed.

Check for pressure in the fuel inlet tube from the fuel line. Check that sound of fuel flowing in the fuel tank can be heard. If no sound can be heard, check the integration relay, fuel pump, ECM and wiring connector.

Check for fuel leaks.

Check that there are no fuel leaks anywhere on the system after performing maintenance. If there is a fuel leak, repair or replace parts if necessary.

Turn the ignition switch off.

Disconnect the intelligent tester from the DLC3.

| 86. CHECK FOR ENGINE OIL LEAKS |

| 87. CHECK FOR ENGINE COOLANT LEAKS |

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

- NOTICE:

- Before performing each inspection, turn the A/C switch OFF.

Fill the radiator with coolant and attach a radiator cap tester.

|

Warm up the engine.

Using a radiator cap tester, increase the pressure inside the radiator to 118 kPa (1.2 kgf*cm, 17 psi), and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator and water pump for leaks. If no external leaks are found, check the heater core, cylinder block and cylinder head.

| 88. CHECK FOR EXHAUST GAS LEAKS |

| 89. CHECK SHIFT LEVER POSITION |

When shifting from the P to the R position with the ignition switch on (IG) and the brake pedal depressed, make sure that the shift lever moves smoothly and moves correctly into the position.

Start the engine and make sure that the vehicle moves forward when shifting from the N to the D position and moves rearward when shifting to the R position. If operation cannot be done as specified, inspect the park/neutral position switch assembly and check the shift lever assembly installation condition.

| 90. CHECK AND ADJUST FRONT WHEEL ALIGNMENT |

- HINT:

| 91. CHECK IGNITION TIMING |

Warm up the engine.

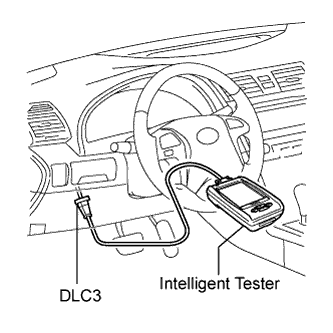

When using the intelligent tester:

Check the ignition timing.Connect the intelligent tester to the DLC3.

Enter DATA LIST mode with the intelligent tester.

- Ignition timing:

- 8 to 12° BTDC at idle

- HINT:

- Refer to the intelligent tester operator's manual for help when selecting the DATA LIST.

|

When not using the intelligent tester:

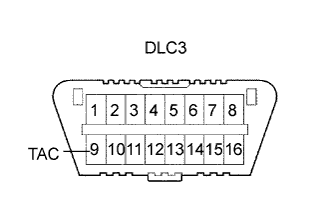

Check the ignition timing.Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

- SST

- 09843-18040

- NOTICE:

- Confirm the terminal numbers before connecting them. Connection with a wrong terminal can damage the engine.

- Turn off all electrical systems before connecting the terminals.

- Perform this inspection after the cooling fan motor is turned off.

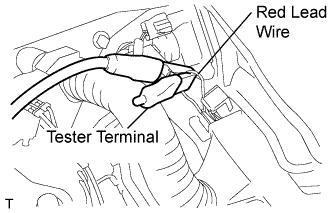

Remove the V-bank cover.

Pull out the red lead wire harness.

Connect the tester terminal of the timing light to the red lead wire as shown in the illustration.

- NOTICE:

- Use a timing light which can detect the first signal.

Check the ignition timing at idle.

- Ignition timing:

- 8 to 12° BTDC at idle

- NOTICE:

- When checking the ignition timing, the transmission should be in neutral.

- HINT:

- Run the engine at 1,000 to 1,300 rpm for 5 seconds, and then check that the engine rpm returns to idle speed.

Disconnect terminals 13 (TC) and 4 (CG) of the DLC3.

Check the ignition timing at idle.

- Ignition timing:

- 12 to 22° BTDC at idle

Confirm that the ignition timing moves to the advanced angle side when the engine rpm is increased.

Remove the timing light.

|

| 92. CHECK ENGINE IDLE SPEED |

Warm up the engine.

When using the intelligent tester:

Check the idle speed.Connect the intelligent tester to the DLC3.

Enter DATA LIST mode with the intelligent tester.

- Idle speed:

- 600 to 700 rpm

- NOTICE:

- When checking the idle speed, the transmission should be in neutral.

- Check the idle speed with the cooling fan off.

- Switch off all accessories and air conditioning before connecting the intelligent tester.

- HINT:

- Refer to the intelligent tester operator's manual for further details.

|

When not using the intelligent tester:

Check the idle speed.Using SST, connect the tachometer test probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18030

Check the idle speed.

- Idle speed:

- 600 to 700 rpm

|

| 93. CHECK CO/HC |

Start the engine.

Run the engine at 2,500 rpm for approximately 180 seconds.

Insert the CO/HC meter testing probe at least 40 cm (1.3 ft) into the tailpipe during idling.

Check CO/HC concentration at idle and/or 2,500 rpm.

- HINT:

- Check regulations and restrictions in your area when performing 2 mode CO/HC concentration testing (engine check at both idle speed and at 2,500 rpm).

- If the CO/HC concentration does not comply with regulations, perform troubleshooting in the order given below.

Check A/F sensor and heated oxygen sensor operation.

See the table below for possible causes, and then inspect and repair.

CO HC Problems Causes Normal High Rough idle - Faulty ignitions:

- Incorrect timing

- Fouled, shorted or improperly gapped plugs

- Incorrect valve clearance

- Leaks in intake and exhaust valves

- Leaks in cylinders

Low High Rough idle

(fluctuating HC reading)- Vacuum leaks:

- PCV hoses

- Intake manifold

- Throttle body

- Brake booster line

- Lean mixture causing misfire

High High Rough idle

(black smoke from exhaust)- Restricted air filter

- Plugged PCV valve

- Faulty SFI system:

- Faulty fuel pressure regulator

- Defective engine coolant temperature sensor

- Defective MAF meter

- Faulty ECM

- Faulty injectors

- Faulty throttle position sensor

- Faulty ignitions:

| 94. CHECK FUNCTION OF THROTTLE BODY |

Inspect the throttle control motor for operating sounds.

Turn the ignition switch on (IG).

When turning the accelerator pedal position sensor lever, check for running sounds of the motor. The motor should be running smoothly without friction sounds.

If operation is not as specified, check the throttle control motor, wiring and ECM (CAMRY_ACV40 RM0000022NJ002X_01_0001.html).

|

| 95. INSTALL FRONT FENDER APRON SEAL RH |

| 96. INSTALL ENGINE UNDER COVER LH |

| 97. INSTALL ENGINE UNDER COVER RH |

| 98. INSTALL V-BANK COVER SUB-ASSEMBLY |

Engage the 3 retainers to install the V-bank cover.

|

| 99. INSTALL COOL AIR INTAKE DUCT SEAL |

Install the intake duct seal with the 7 clips.

|

| 100. CHECK ABS SPEED SENSOR SIGNAL |