Wiper And Washer System Headlight Cleaner Motor And Relay Circuit

DESCRIPTION

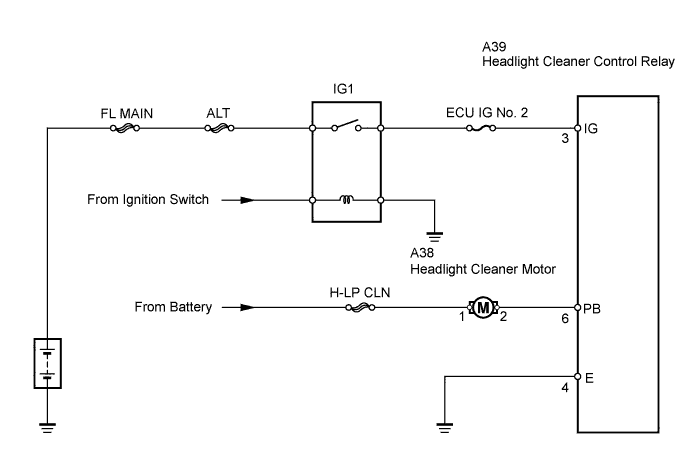

WIRING DIAGRAM

INSPECTION PROCEDURE

INSPECT FUSE (ECU IG NO. 2)

INSPECT HEADLIGHT CLEANER MOTOR AND PUMP ASSEMBLY

CHECK HARNESS AND CONNECTOR (HEADLIGHT CLEANER MOTOR CIRCUIT)

WIPER AND WASHER SYSTEM - Headlight Cleaner Motor and Relay Circuit |

DESCRIPTION

This circuit provides power to the headlight cleaner control relay.The headlight cleaner control relay receives the signal from the switch, etc., to operate the headlight cleaner motor and pump.

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.INSPECT FUSE (ECU IG NO. 2) |

Remove the ECU IG No. 2 fuse from the instrument panel J/B.

Measure the resistance of the fuse.

- Standard resistance:

- Below 1 Ω

| 2.INSPECT HEADLIGHT CLEANER MOTOR AND PUMP ASSEMBLY |

Disconnect the A38 headlight cleaner motor and pump assembly connector.

Connect the positive (+) battery lead to terminal A38-1 of the headlight cleaner motor and pump assembly, and the negative (-) battery lead to terminal A38-2.

- OK:

- Operation sounds are heard.

| | REPLACE HEADLIGHT CLEANER MOTOR AND PUMP ASSEMBLY |

|

|

| 3.CHECK HARNESS AND CONNECTOR (HEADLIGHT CLEANER MOTOR CIRCUIT) |

Connect the A38 headlight cleaner motor and pump assembly connector.

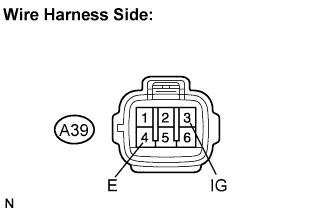

Disconnect the A39 headlight cleaner control relay connector.

Measure the voltage according to the value(s) in the table below.

- Standard voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

A39-3 (IG) - Body ground

| Ignition switch ON

| 10 to 14 V

|

A39-6 (PB) - Body ground

| Always

| 10 to 14 V

|

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

| Specified Condition

|

A39-4 (E) - Body ground

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (HEADLIGHT CLEANER CONTROL RELAY - BATTERY) |

|

|

| OK |

|

|

|

| PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE |

|