Engine -- Inspection |

| 1. INSPECT ENGINE COOLANT |

Inspect the engine coolant (CAMRY_ACV40 RM000000V1Q01EX.html).

| 2. INSPECT ENGINE OIL |

Inspect the engine oil (CAMRY_ACV40 RM000001R0T011X.html).

| 3. INSPECT BATTERY |

Inspect the battery (CAMRY_ACV40 RM000001AR900IX.html).

| 4. INSPECT SPARK PLUGS |

Inspect the spark plugs (CAMRY_ACV40 RM000001QVP01BX_01_0002.html).

| 5. INSPECT AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY |

Remove the air cleaner filter element sub-assembly.

Visually check that there is no dirt, blockage, and/or damage to the air cleaner filter element.

- HINT:

- If there is any dirt or a blockage in the air cleaner filter element, clean it with compressed air.

- If any dirt or a blockage remains even after cleaning the air cleaner filter element with compressed air, replace it.

| 6. INSPECT IGNITION TIMING |

Warm up the engine.

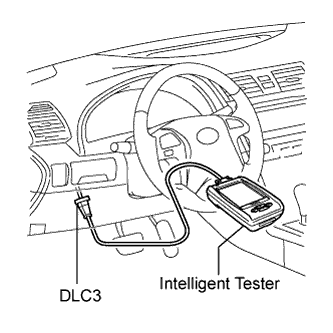

When using the intelligent tester:

Check the ignition timing.Connect the intelligent tester to the DLC3.

Enter DATA LIST MODE on the intelligent tester.

- Ignition timing:

- 8 to 12° BTDC at idle

- HINT:

- Refer to the intelligent tester operator's manual for help when selecting the DATA LIST.

|

When not using the intelligent tester:

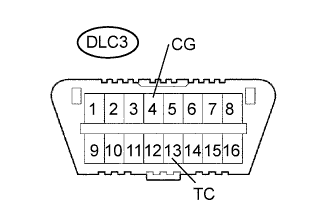

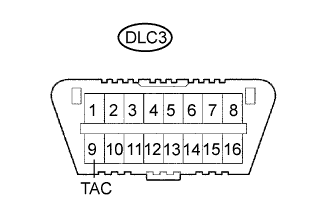

Check the ignition timing.Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

- SST

- 09843-18040

- NOTICE:

- Confirm the terminal numbers before connecting them. Connection with a wrong terminal can damage the engine.

- Turn off all electrical systems before connecting the terminals.

- Perform this inspection after the cooling fan motor is turned off.

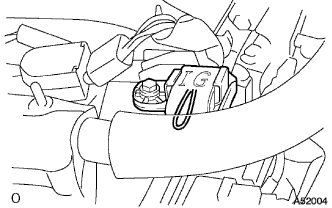

Remove the No. 1 engine cover.

Pull out the wire harness as shown in the illustration. Connect the clip of the timing light to the wire harness.

- NOTICE:

- Use a timing light which can detect the first signal.

- After checking, be sure to tape the wire harness.

Check the ignition timing at idle.

- Ignition timing:

- 8 to 12° BTDC at idle

- NOTICE:

- When checking the ignition timing, the transmission should be in neutral.

- HINT:

- After engine rpm is kept at 1,000 to 1,300 rpm for 5 seconds, check that it returns to idle speed.

Disconnect terminals 13 (TC) and 4 (CG) of the DLC3.

Check the ignition timing at idle.

- Ignition timing:

- 5 to 15° BTDC at idle

Confirm that the ignition timing moves to the advanced angle side when the engine rpm is increased.

Remove the timing light.

|

| 7. INSPECT ENGINE IDLE SPEED |

Warm up the engine.

|

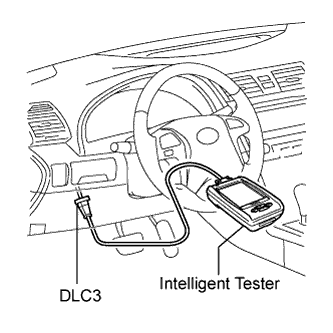

When using the intelligent tester:

Check the idle speed.Connect the intelligent tester to the DLC3.

- HINT:

- Refer to the intelligent tester operator's manual for further details.

Enter DATA LIST MODE on the intelligent tester.

- Idle speed:

Item Specified Condition M/T 650 to 750 rpm A/T 610 to 710 rpm

- NOTICE:

- When checking the idle speed, the transmission should be in neutral.

- Check the idle speed with the cooling fan off.

- Switch off all accessories and air conditioning before connecting the intelligent tester.

When not using the intelligent tester:

Check the idle speed.Using SST, connect the tachometer tester probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18030

Check the idle speed.

- Idle speed:

Item Specified Condition M/T 650 to 750 rpm A/T 610 to 710 rpm

|

| 8. INSPECT COMPRESSION |

Warm up and stop the engine.

Disconnect the injector connectors.

Remove the ignition coils.

Remove the spark plugs.

Check the cylinder compression pressure.

Insert a compression gauge into the spark plug hole.

Fully open the throttle.

While cranking the engine, measure the compression pressure.

- Compression pressure:

- 1.360 MPa (13.9 kgf/ cm2, 198 psi)

- Minimum pressure:

- 0.98 MPa (10 kgf/ cm2, 142 psi)

- Difference between each cylinder:

- 100 kPa (1.0 kgf/ cm2, 14 psi)

- NOTICE:

- Always use a fully charged battery to obtain an engine speed of 250 rpm or more.

- Check the other cylinders' compression pressure in the same way.

- This measurement must be done as quickly as possible.

If the cylinder compression is low, pour a small amount of engine oil into the cylinder through the spark plug hole and inspect again.

- HINT:

- If adding oil increases the compression, the piston rings and/or cylinder bore may be worn or damaged.

- If pressure stays low, a valve may be stuck or seated improperly, or there may be leakage in the gasket.

|

| 9. INSPECT CO/HC |

Start the engine.

Run the engine at 2,500 rpm for approximately 180 seconds.

Insert the CO/HC meter testing probe at least 40 cm (1.3 ft) into the tailpipe during idling.

Immediately check CO/HC concentration at idle and/or 2,500 rpm.

- HINT:

- Complete the measuring within 3 minutes.

- Check regulations and restrictions in your area when performing 2 mode CO/HC concentration testing (engine check at both idle speed and at 2,500 rpm).

If the CO/HC concentration does not comply with regulations, troubleshoot in the order given below.

Check A/F sensor operation (CAMRY_ACV40 RM0000012OG006X_01_0001.html).

See the table below for possible causes, and then inspect and repair.

CO HC Problems Causes Normal High Rough idle - Faulty ignitions:

- Incorrect timing

- Fouled, shorted or improperly gapped plugs

- Incorrect valve clearance

- Leaky intake and exhaust valves

- Leaky cylinders

Low High Rough idle

(fluctuating HC reading)- Vacuum leaks:

- PCV hoses

- Intake manifold

- Throttle body

- Brake booster line

- Lean mixture causing misfire

High High Rough idle

(black smoke from exhaust)- Restricted air filter

- Plugged PCV valve

- Faulty SFI system:

- Faulty pressure regulator

- Defective engine coolant temperature sensor

- Defective MAF meter

- Faulty ECM

- Faulty injectors

- Faulty throttle position sensor

- Faulty ignitions: