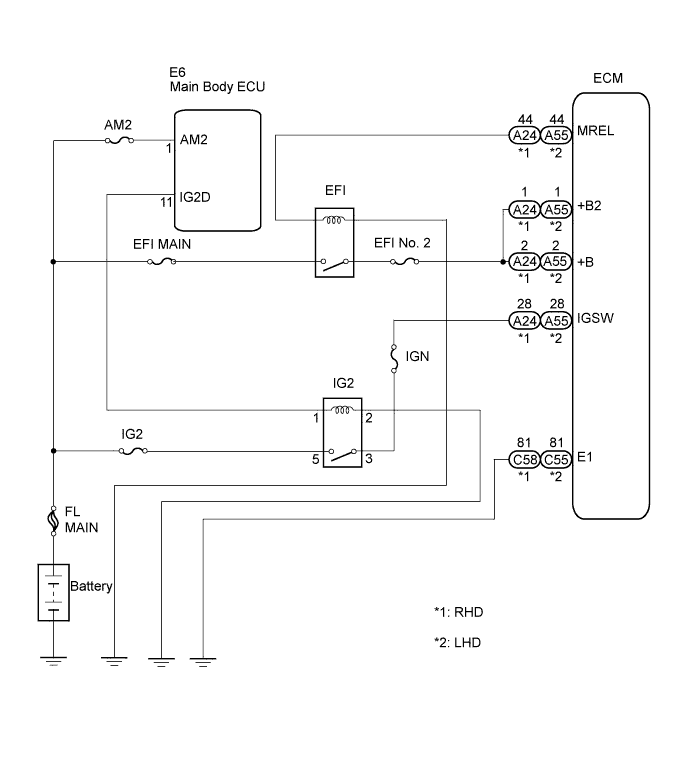

Sfi System Ecm Power Source Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK HARNESS AND CONNECTOR (ECM - BODY GROUND)

CHECK ENGINE ROOM JUNCTION BLOCK (EFI RELAY VOLTAGE)

INSPECT EFI MAIN FUSE

CHECK HARNESS AND CONNECTOR (ENGINE ROOM JUNCTION BLOCK - BATTERY)

INSPECT ENGINE ROOM JUNCTION BLOCK (EFI RELAY)

INSPECT EFI NO. 2 FUSE

CHECK HARNESS AND CONNECTOR (ECM - ENGINE ROOM JUNCTION BLOCK)

INSPECT ECM (IGSW VOLTAGE)

INSPECT IGNITION RELAY NO. 2

CHECK HARNESS AND CONNECTOR (IG2 RELAY - BODY GROUND)

CHECK HARNESS AND CONNECTOR (ECM - BODY GROUND)

SFI SYSTEM - ECM Power Source Circuit |

DESCRIPTION

When the engine switch is turned on (IG), the battery voltage is applied to terminal IGSW of the ECM. The ECM MREL output signal causes a current to flow to the coil, closing the contacts of the EFI MAIN relay and supplying power to terminal +B of the ECM.If the engine switch is turned off, the ECM holds the EFI MAIN relay ON for a maximum of 2 seconds to allow for the initial setting of the throttle valve.When the engine switch is turned on (IG), voltage from the ECM's MREL terminal applies to the engine room junction block (EFI relay). This causes the contacts of the engine room junction block (EFI relay) to close, which supplies power to terminal +B or +B1 of the ECM.

WIRING DIAGRAM

INSPECTION PROCEDURE

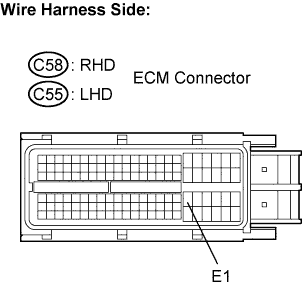

| 1.CHECK HARNESS AND CONNECTOR (ECM - BODY GROUND) |

Disconnect the C58 (RHD) or C55 (LHD) ECM connector.

Measure the resistance between the terminals.

- Standard resistance:

- RHD:

Tester Connection

| Specified Condition

|

E1 (C58-81) - Body ground

| Below 1 Ω

|

- LHD:

Tester Connection

| Specified Condition

|

E1 (C55-81) - Body ground

| Below 1 Ω

|

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

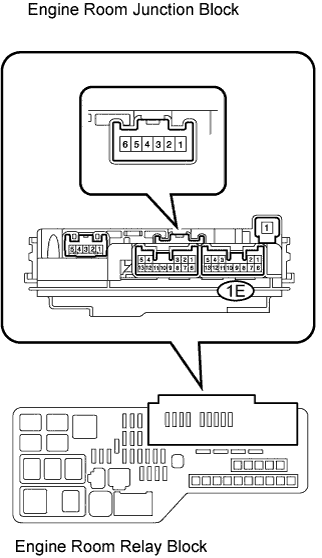

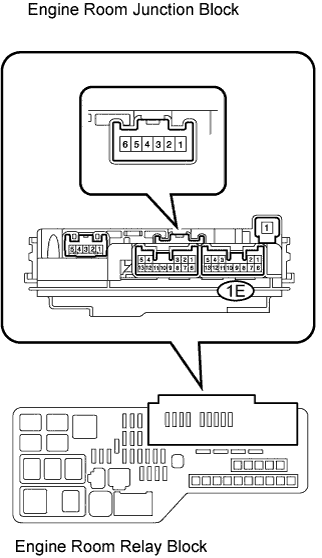

| 2.CHECK ENGINE ROOM JUNCTION BLOCK (EFI RELAY VOLTAGE) |

Remove the engine room junction block from the engine room R/B.

Turn the engine switch on (IG).

Measure the voltage between the terminals.

- Standard voltage:

Tester Connection

| Specified Condition

|

1E-6 - Body ground

| 11 to 14 V

|

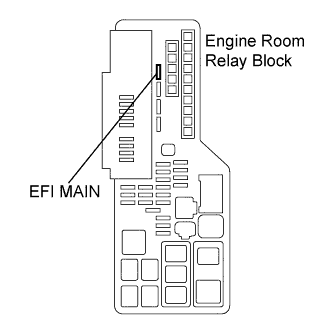

Remove the EFI MAIN fuse from the engine room R/B.

Measure the EFI MAIN fuse resistance.

- Standard resistance:

- Below 1 Ω

Reinstall the EFI MAIN fuse.

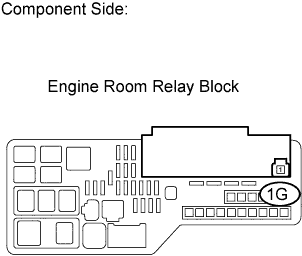

| 4.CHECK HARNESS AND CONNECTOR (ENGINE ROOM JUNCTION BLOCK - BATTERY) |

Disconnect the negative battery terminal.

Disconnect the positive battery terminal.

Remove the engine room junction block from the engine room R/B.

Measure the resistance between the terminals.

- Standard resistance:

- Check for open:

Tester Connection

| Specified Condition

|

1G-1 - Positive battery terminal

| Below 1 Ω

|

- Check for short:

Tester Connection

| Specified Condition

|

1G-1 or Positive battery terminal - Body ground

| 10 kΩ or higher

|

Reinstall the engine room junction block.

Reconnect the positive battery terminal.

Reconnect the negative battery terminal.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 5.INSPECT ENGINE ROOM JUNCTION BLOCK (EFI RELAY) |

Remove the engine room junction block from the engine room R/B.

Measure the resistance between the terminals.

- Standard resistance:

Tester Connection

| Specified Condition

|

1E-6 - 1E-12

| 10 kΩ or higher

|

1E-6 - 1E-12

| Below 1 Ω

(Apply battery voltage between terminals 1E-9 and 1E-11)

|

Reinstall the engine room junction block.

| | REPLACE ENGINE ROOM JUNCTION BLOCK |

|

|

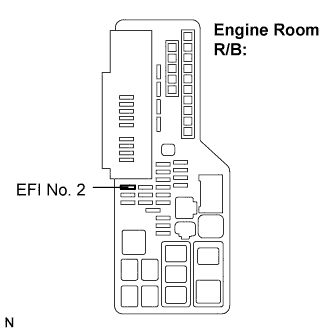

Remove the EFI No. 2 fuse from the engine room R/B.

Measure the EFI No. 2 fuse resistance.

- Standard resistance:

- Below 1 Ω

Reinstall the EFI No. 2 fuse.

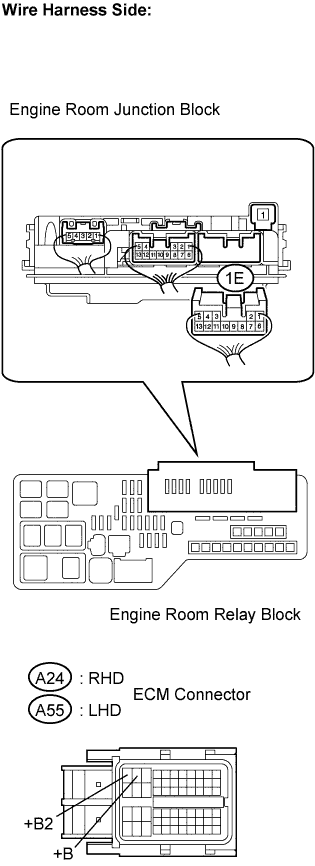

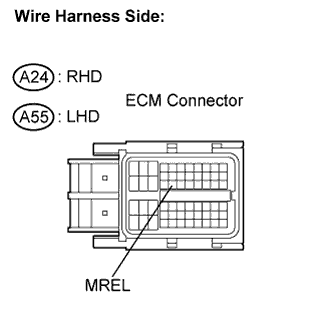

| 7.CHECK HARNESS AND CONNECTOR (ECM - ENGINE ROOM JUNCTION BLOCK) |

Disconnect the A24 (RHD) or A55 (LHD) ECM connector.

Remove the engine room junction block from the engine room R/B.

Measure the resistance between the terminals.

- Standard resistance (Check for open):

- RHD:

Tester Connection

| Specified Condition

|

1E-6 - +B (A24-2)

| Below 1 Ω

|

1E-6 - +B2 (A24-1)

| Below 1 Ω

|

- LHD:

Tester Connection

| Specified Condition

|

1E-6 - +B (A55-2)

| Below 1 Ω

|

1E-6 - +B2 (A55-1)

| Below 1 Ω

|

- Standard resistance (Check for open):

- RHD:

Tester Connection

| Specified Condition

|

1E-6 or +B (A24-2) - Body ground

| 10 kΩ or higher

|

1E-6 or +B2 (A24-1) - Body ground

| 10 kΩ or higher

|

- LHD:

Tester Connection

| Specified Condition

|

1E-6 or +B (A55-2) - Body ground

| 10 kΩ or higher

|

1E-6 or +B2 (A55-1) - Body ground

| 10 kΩ or higher

|

Reinstall the engine room junction block.

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 8.INSPECT ECM (IGSW VOLTAGE) |

Disconnect the A24 (RHD) or A55 (LHD) ECM connector.

Measure the voltage between the terminals.

- Standard voltage:

- RHD:

Tester Connection

| Specified Condition

|

IGSW (A24-28) - Body ground

| 11 to 14 V

|

- LHD:

Tester Connection

| Specified Condition

|

IGSW (A55-28) - Body ground

| 11 to 14 V

|

Reconnect the ECM connector.

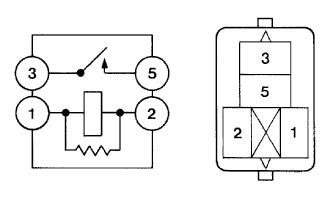

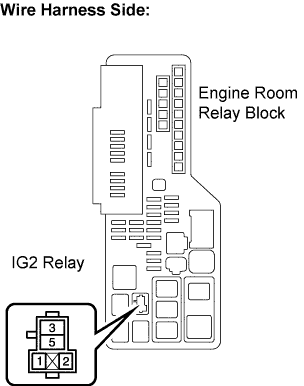

| 9.INSPECT IGNITION RELAY NO. 2 |

Remove the IG2 relay from the engine room R/B.

Measure the resistance between the terminals.

- Standard resistance:

Tester Connection

| Specified Condition

|

3 - 5

| 10 kΩ or higher

|

3 - 5

| Below 1 Ω

(Apply battery voltage between terminals 1 and 2)

|

Reinstall the IG2 relay.

| | REPLACE IGNITION RELAY NO. 2 |

|

|

| 10.CHECK HARNESS AND CONNECTOR (IG2 RELAY - BODY GROUND) |

Remove the IG2 relay from the engine room R/B.

Measure the resistance between the terminals.

- Standard resistance:

Tester Connection

| Specified Condition

|

IG2 relay terminal 2 - Body ground

| Below 1 Ω

|

Reinstall the IG2 relay.

- Result:

| | GO TO ENTRY AND START SYSTEM |

|

|

| B |

|

|

|

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 11.CHECK HARNESS AND CONNECTOR (ECM - BODY GROUND) |

Disconnect the A24 (RHD) or A55 (LHD) ECM connector.

Measure the resistance between the terminals.

- Standard resistance:

- RHD:

Tester Connection

| Specified Condition

|

MREL (A24-24) - Body ground

| Below 1 Ω

|

- LHD:

Tester Connection

| Specified Condition

|

MREL (A55-24) - Body ground

| Below 1 Ω

|

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|