Automatic Transaxle System -- Hydraulic Test |

| PERFORM HYDRAULIC TEST |

Measure the line pressure.

- NOTICE:

- Perform the test at the normal operating ATF (Automatic Transmission Fluid) temperature: 50 to 80°C (122 to 176°F).

- The line pressure test should always be carried out in pairs. One technician should observe the conditions of wheels or wheel stoppers outside the vehicle while the other is performing the test.

- Be sure to prevent SST hose from interfering with the exhaust pipe.

- This check must be conducted after checking and adjusting the engine.

- Perform the test when the A/C is OFF.

- When conducting the stall test, do not continue for more than 5 seconds.

Warm up the ATF (Automatic Transmission Fluid).

Lift the vehicle up.

Remove the engine under cover.

Connect the intelligent tester to the DLC3.

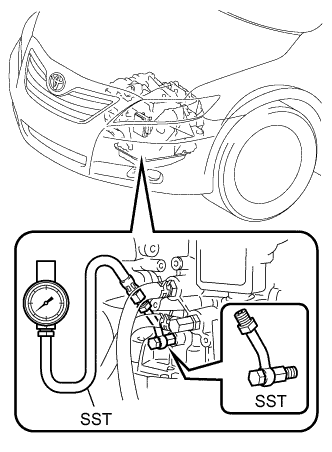

Remove the test plug on the transaxle case front left side and install the SST.

- SST

- 09992-00095(09992-00231,09992-00271)

Start the engine.

Shift to the D position, and then use the intelligent tester to hold 3rd gear using active test. Measure the line pressure while the engine is idling.

Specified line pressure: Condition D position kPa (kgf/cm2, psi) Idling 360 to 430 kPa

(3.7 to 4.4 kgf/cm2, 52 to 62 psi)Turn the ignition switch OFF.

Disconnect the connector of the TCM.

- HINT:

- Disconnect the connector only when performing the D position stall test.

Start the engine.

Firmly depress the brake pedal, shift to the D position, depress the accelerator pedal all the way down, and check the line pressure while the stall test is performed.

Specified line pressure: Condition D position kPa (kgf / cm2, psi) Stall test 1160 to 1350 kPa

(11.8 to 13.8 kgf/cm2, 168 to 196 psi)Turn the ignition switch OFF.

Connect the TCM connector, depress the brake pedal firmly, shift to the R position, and check the line pressure while the engine is idling and during the stall test.

Specified line pressure: Condition R position kPa (kgf / cm2, psi) Idling 800 to 950 kPa

(8.2 to 9.7 kgf/cm2, 116 to 138 psi)Stall test 1900 to 2200 kPa

(19.4 to 22.4 kgf/cm2, 276 to 319 psi)Remove the SST, and install the test plug.

Clear the DTC.

Evaluation: Problem Possible cause Measured values are higher than the specified value in all positions - Shift solenoid valve (SLT) defective

- Regulator valve defective

Measured values are lower than the specified value in all positions - Shift solenoid valve (SLT) defective

- Regulator valve defective

- Oil pump defective

Pressure is low in the D position only - D position circuit fluid leak

- Clutch No. 1 (C1) defective

Pressure is low in the R position only - R position circuit fluid leak

- Brake No. 2 (B2) defective

- Brake No. 3 (B3) defective

- Shift solenoid valve (SLT) defective

|