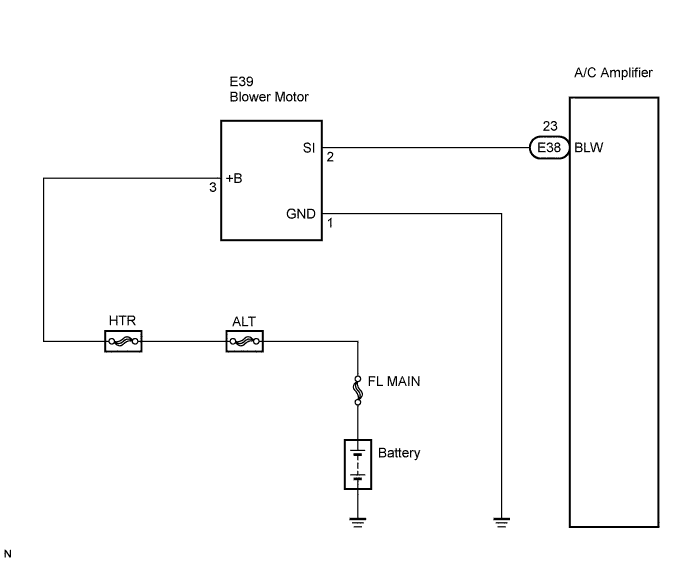

Air Conditioning System Blower Motor Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

PERFORM ACTIVE TEST USING INTELLIGENT TESTER

INSPECT FUSIBLE LINK (HTR)

CHECK HARNESS AND CONNECTOR (BLOWER MOTOR - BODY GROUND)

CHECK HARNESS AND CONNECTOR (BLOWER MOTOR - BATTERY)

CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - BLOWER MOTOR)

INSPECT BLOWER MOTOR

INSPECT AIR CONDITIONING AMPLIFIER

AIR CONDITIONING SYSTEM - Blower Motor Circuit |

DESCRIPTION

The blower motor is operated by signals from the A/C amplifier. The blower motor speed is controlled using various duty ratios.

The blower motor is operated by signals from the A/C amplifier. The blower motor speed is controlled using various duty ratios.Duty Ratio:

- The duty ratio is the ratio of the blower motor ON time (A) to the total of the blower motor ON and OFF time (A + B).

- The blower motor controller controls the blower motor speed.

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.PERFORM ACTIVE TEST USING INTELLIGENT TESTER |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

Select the item below in the Active Test and then check that the blower motor operates.

Active Test / Air Conditioner:Item

| Test Details / Display (Range)

| Diagnostic Note

|

Blower Motor

(Blower Motor)

| Blower motor / Min.: Level 01, Max.: Level 31

| -

|

- Result:

Result

| Proceed to

|

OK

| A

|

NG (blower motor does not operate)

| B

|

NG (blower motor operates but does not change speed)

| C

|

| A |

|

|

|

| PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE |

|

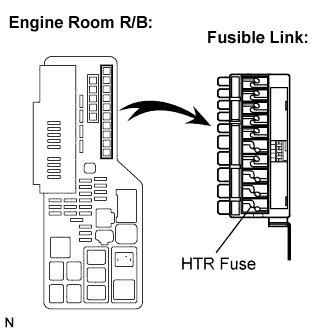

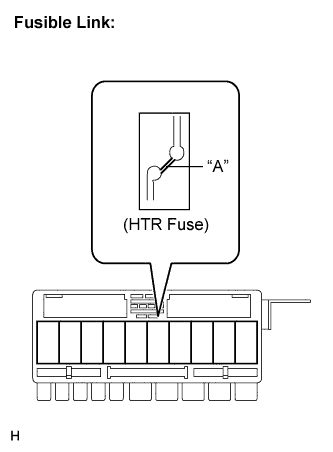

| 2.INSPECT FUSIBLE LINK (HTR) |

Remove the fusible link from the engine room R/B.

Check if the fusible link is melted.

- OK:

- The point indicated by "A" is not melted.

Install the fusible link to the engine room R/B with the nut.

| | REPLACE FUSIBLE LINK (HTR) |

|

|

| 3.CHECK HARNESS AND CONNECTOR (BLOWER MOTOR - BODY GROUND) |

Disconnect the blower motor connector.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

E39-1 (GND) - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 4.CHECK HARNESS AND CONNECTOR (BLOWER MOTOR - BATTERY) |

Disconnect the blower motor connector.

Measure the voltage according to the value(s) in the table below.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

E39-3 (+B) - Body ground

| Always

| 10 to 14 V

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

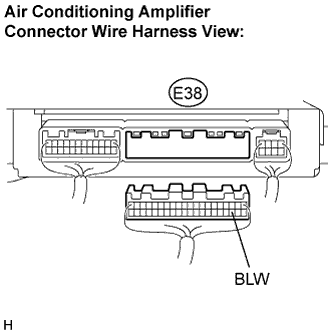

| 5.CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - BLOWER MOTOR) |

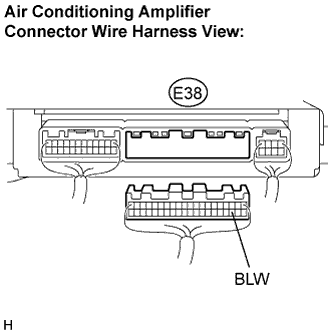

Disconnect the A/C amplifier connector.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

(Symbols)

| Condition

| Specified Condition

|

E39-2 (SI) - E38-23 (BLW)

| Always

| Below 1 Ω

|

E39-2 (SI) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

Reconnect the connector to the blower motor.

Measure the voltage on the A/C amplifier connector side according to the value(s) in the table below.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

E38-23 (BLW) - Body ground

| Ignition switch: ON

| 4.5 to 5.5 V

|

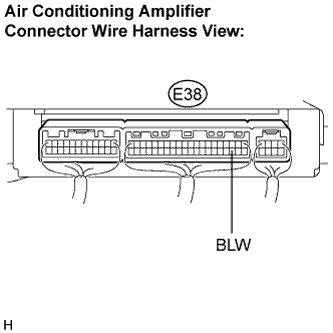

| 7.INSPECT AIR CONDITIONING AMPLIFIER |

Remove the A/C amplifier.

Reconnect the connector to the A/C amplifier.

Turn the ignition switch to the ON position.

Turn the blower switch ON.

Measure the waveform between terminal E38-23 (BLW) of the A/C amplifier and body ground.

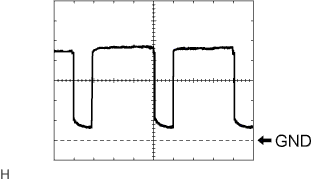

- OK:

- Waveform is as shown in the illustration.

- HINT:

- Waveform varies with the blower level.

Item

| Contents

|

Tool setting

| 1 V/DIV., 500 μs/DIV.

|

Vehicle condition

| Ignition switch: ON

Blower switch: ON

|

| | REPLACE AIR CONDITIONING AMPLIFIER |

|

|

| OK |

|

|

|

| PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE |

|